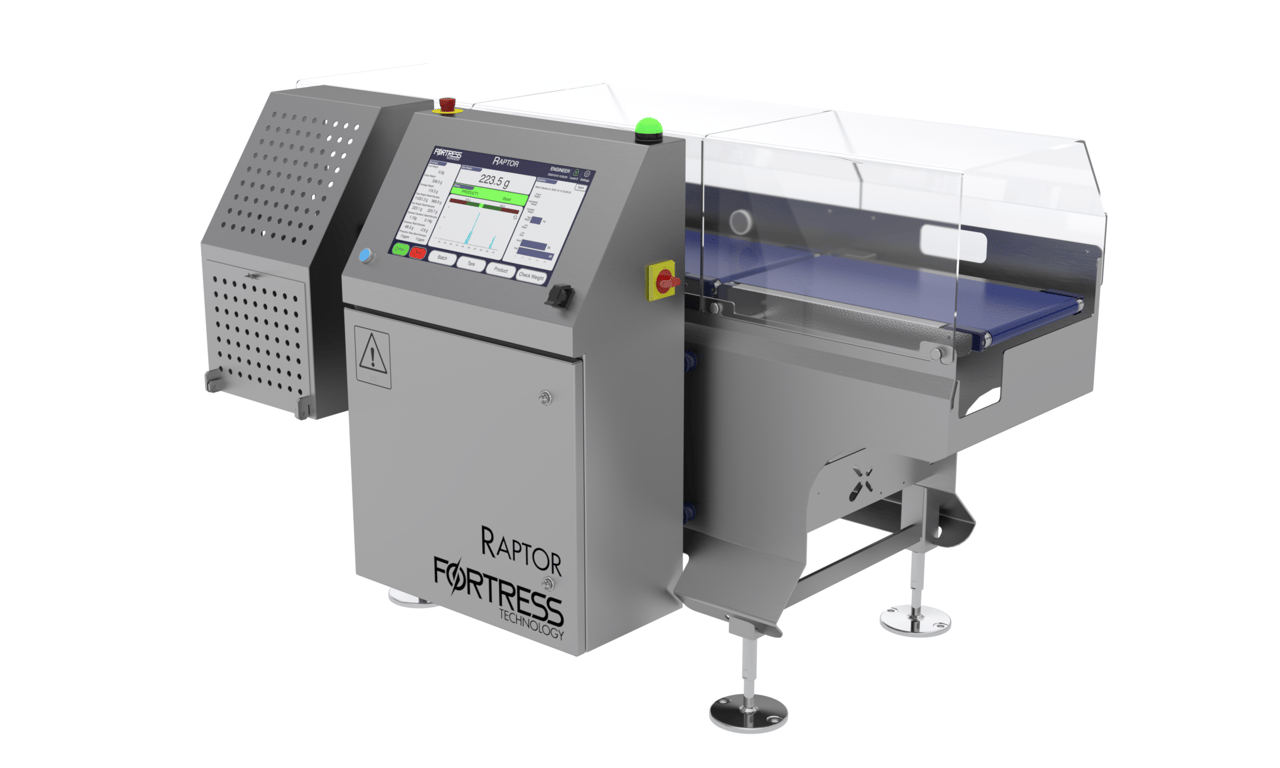

“Depending on applications, foreign objects can be detected using color cameras or hyperspectral cameras, which take multiple images at different wavelengths,” says Zhao. “Some foreign objects may appear in similar colors as the food products, but will show much higher contrast under different wavelength of source light.”

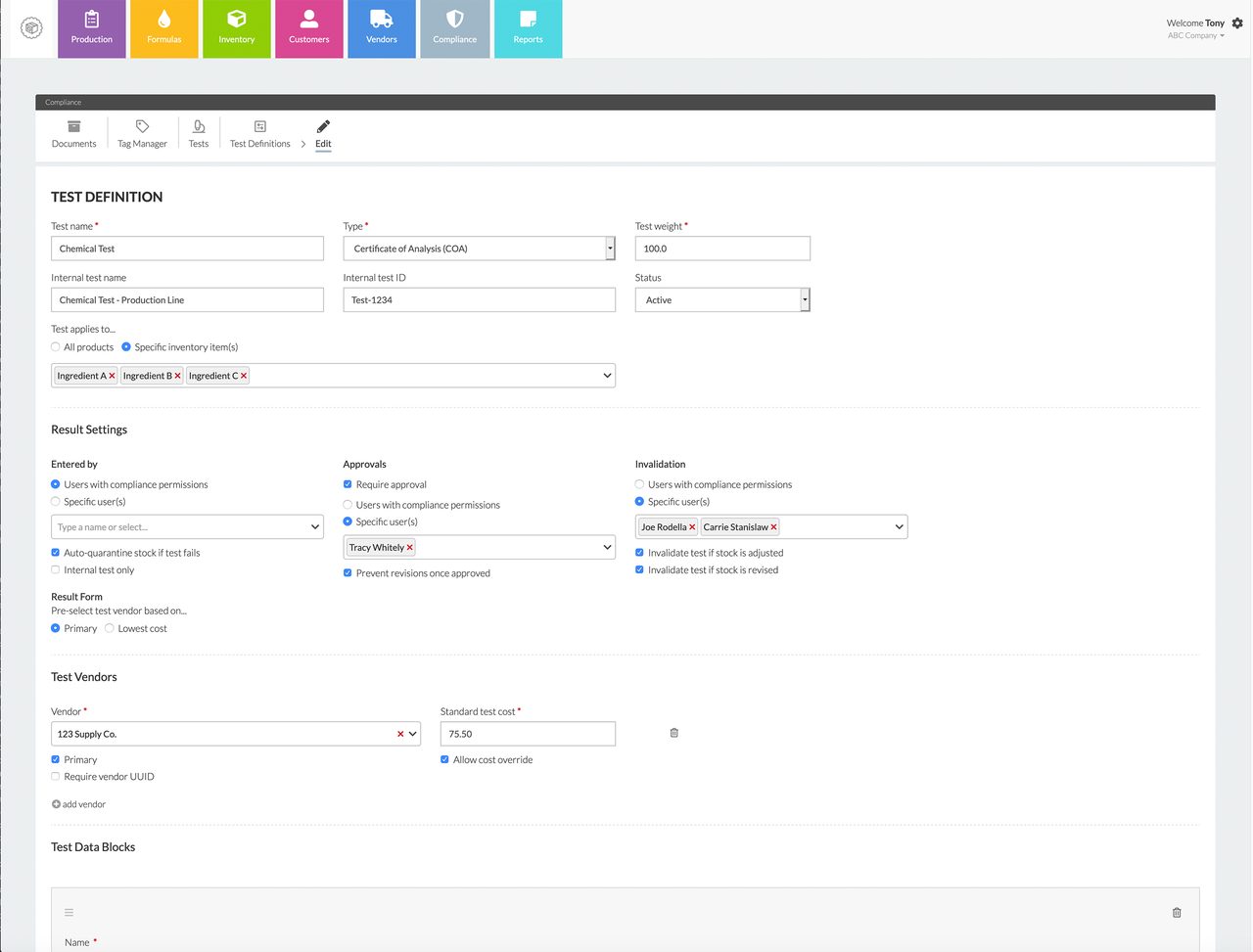

Eric Weisbrod, vice president, product management, InfinityQS, Fairfax, VA, says that all of the company’s software solutions directly address the needs of all food manufacturers as well as snack food and bakery operations. “Our software products are used not just for process control reasons, but also to directly support your HAACP, GMP, SSOP, sanitation, and other food-specific data collection requirements,” he notes.

There are several key benefits that this industry can enjoy with a centralized quality system, including data-driven insights, data accessibility, and data assurance, Weisbrod says. “Every organization is required to collect different types of data for process improvement, compliance, customer requirements, etc. This data is already being collected, so it should be turned into actionable intelligence by having tools to aggregate and roll up data so it can be meaningfully analyzed and, most importantly, acted upon.”

Data accessibility is directly applicable to audits and traceability for all kinds of checks (HACCP, GMP, SSOP, etc.), says Weisbrod. “Simply having the data available in a centralized, electronic system means results are immediately available to answer internal questions, customer requests, and audit requests. This is vastly superior to using paper and pencil, or a collection of scattered spreadsheets or local applications.”

Weisbrod says that manufacturers have similar concerns regarding their quality checks: