Automation

report

The BOTTOM LINE

- Addressing the labor market

- Flexible and versatile solutions

- Preparing for future challenges

Automating into the future

Strategies for implementing automation and robotics for select operational processes help companies meet demand amidst a persistent labor shortage.

Douglas J. Peckenpaugh, Group Editorial Director

As the dark days of the COVID-19 pandemic descended upon America in early 2020, the American population began reacting to their new reality—and it was clear that snack and bakery production across the country would face a clear challenge. People were stocking up on supplies at an alarming rate, and the rush was on to keep grocery store shelves stocked.

This mad rush to stock up on supplies prompted snack and bakery companies to increase throughput, add new shifts to keep facilities producing at peak capacity, often with a reduced workforce. As a result, many operations clearly saw their limitations—aspects of production that could stand updating.

A clear strategy for updating capabilities while simultaneously addressing staffing challenges is investing in robotics and automation to streamline key aspects of production.

Meeting needs

“It is really a challenging, yet exciting, time to be an automation supplier in this industry,” says Rick Hoskins, CEO, Colborne Foodbotics, Lake Forest, IL. “While I would argue demand for automation is at an all-time high, we have a significant number of challenges in the supply chain. It’s really a perfect storm of issues, from significant price increases across the board to limited supply of most components and raw materials.”

Courtesy of Colborne Foodbotics

“Cobots enhance processes by alleviating the requirements placed on humans and make production more efficient.”

— Sean Riley, senior director, media and industry communications, PMMI

Courtesy of PMMI

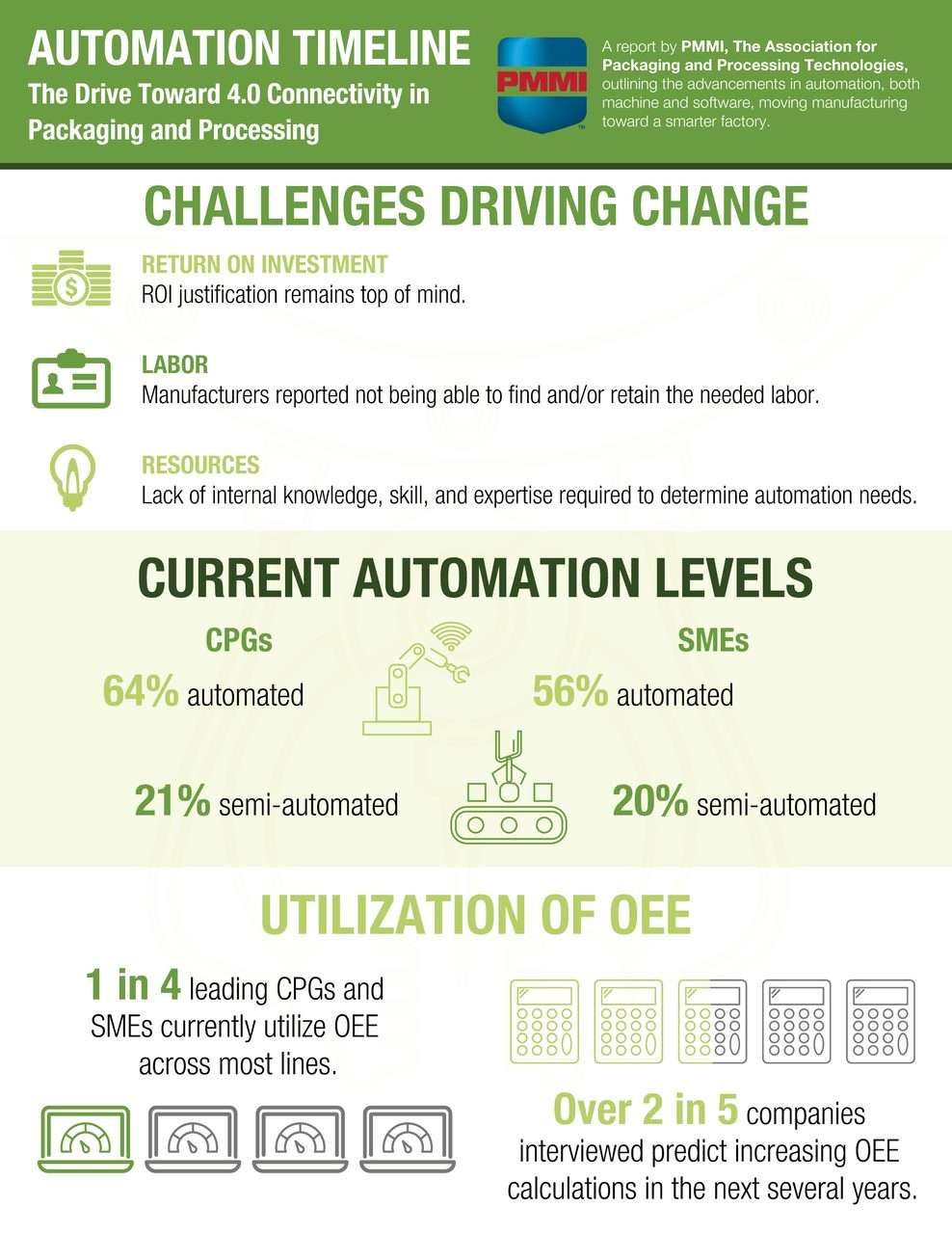

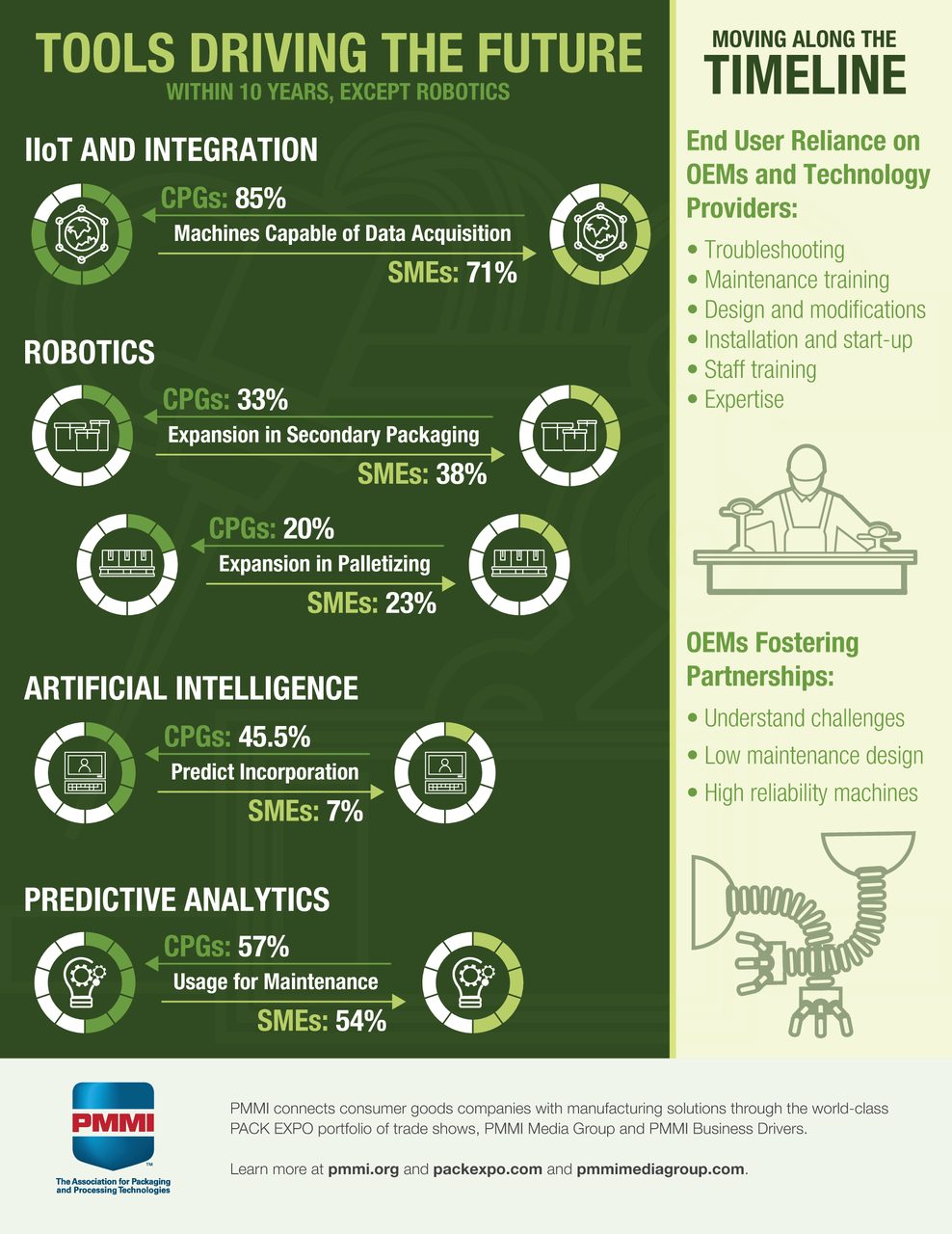

A recent PMMI white paper, “Automation Timeline: The Drive Toward 4.0 Connectivity in Packaging and Processing,” found 13 percent of surveyed respondents—mostly from larger CPG companies—report they accelerated their timelines for automation as a result of COVID-19, says Sean Riley, senior director, media and industry communications, PMMI, Herndon, VA. “As manufacturers deal with an evolving and possibly permanently changed supply chain, companies have reestablished their embrace of robotics.” Manufacturers have concerns about the workforce, and are looking into robotics technology to keep operations afloat.

“One of the fastest areas of growth for robot usage in manufacturing is collaborative robots (cobots),” says Riley. “Cobots enhance processes by alleviating the requirements placed on humans and make production more efficient. They were on the rise before the outbreak of COVID-19 because of their versatility and ability to be quickly redeployed elsewhere with only minimal reprogramming. These advantages make cobots a potential solution during the COVID-19 pandemic to ease the transition of companies into new operational realities as labor availability fluctuates and production schedules shift.”

Meeting market demands for a diverse—but conceptually integrated—product sets broadens revenue potential. “The snack food and bakery market is a highly volatile market, with healthier ingredients and options such as low-calorie, organic, gluten-free, and added vitamins/nutritional ingredients still gaining popularity,” says Billy Goodman, managing director, Cama North America, Buffalo Grove, IL. Automation can help companies keep up with production demands, while addressing today’s labor challenges.

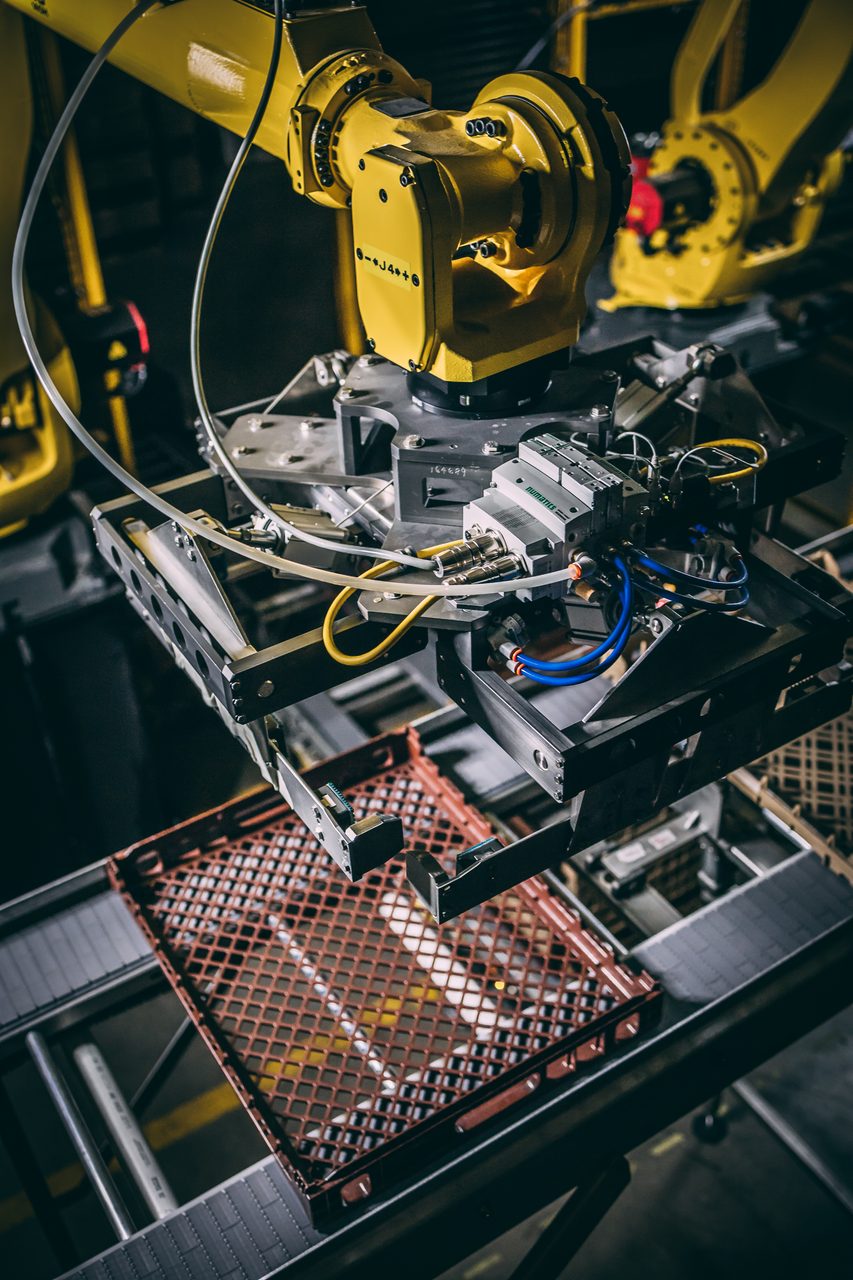

“The desire to implement flexible automation, including robots, is strong in the snack and bakery market,” says Dean Elkins, segment leader, handling, Yaskawa Motoman, Miamisburg, OH. “In some cases, this is driven by shorter batch runs requiring faster equipment changeover and setup. In some cases, the need for flexibility is driven by using new packaging designs which robots can easily accommodate.” Operators can now choose from an increased range of sanitary robot and cobot designs for primary and secondary packaging applications.

Courtesy of Yaskawa Motoman

The market is seeing continual innovation in product and packaging formats from traditional designs, Goodman notes, as well as a move toward more sustainable packaging—but perhaps in single serve and/or shelf-ready packaging. That can add complexity to processes for cartoners, case packers, sleeving systems, and loading systems—machines that gain value when they have the flexibility to run multiple package formats on the same machine. Cama Group’s high-speed IF Series Case Packer is a Monoblock Loading Unit, with full robotic monoblocks, that can run pouches, bags, cartons, rigid containers, flow-wrapped products, and trays.

“Cama’s advanced technology also delivers connectivity to enterprise systems for batch data capture, ERP, and remote maintenance,” says Goodman.

Artificial intelligence (AI) sits at the heart of many robotics and automation projects, with machines replicating processes traditionally executed by people. “Most snack and bakery manufacturers have at most only started to think about AI,” says Liran Akavia, COO and co-founder, Seebo, Tel Aviv, Israel. “In fact, in many cases, they don’t even have basic data on their production lines.” He notes some large producers like Mondelez International, General Mills, and Nestlé already use AI to reduce waste and optimize their production processes.

“Companies today are seeking ways to maintain or increase output and profitability,” says Sebastien Schmitt, robotics director, North America, Staubli Corp., Duncan, SC. “They can no longer do this by simply adding more workers, since many either cannot work or choose not to work in those environments. Additionally, many companies are competing for a limited labor pool by offering higher hourly wages, hiring bonuses, and enhanced benefits packages. This combination of immediate and long-term labor costs is raising the cost per hour of labor.”

This has pushed snack and bakery companies to use resources other than manual labor to maintain or increase output with their existing production lines, says Schmitt. “This is driving them to invest in automating as much of their process as possible.”

Courtesy of Staubli Corp.

Distancing regulations during the COVID-19 pandemic also illustrated personnel challenges on production lines. “Automation has played a role to mitigate the risk of spread,” says Schmitt.

“If there were any fence-sitters before the pandemic hit, there can’t be many left now,” says Martin Riis, business development manager, Apex Motion Control, Surrey, British Columbia. “Labor shortages continue to be one of the greatest challenges on the production floor, specifically manual labor. We are experiencing demand for robotics and system automation at a record pace with no signs of slowing down. Our cobots are being built and shipped around the world to help fill the gaps left by a diminished manual labor force.”

At the beginning of the COVID-19 pandemic, demand and sales for some bakery and other food products went through the roof, notes Riis. Meanwhile, the labor force was reduced, with some production personnel ceasing work for various reasons.

As a result of COVID-19, the snack food and bakery market has also seen an increased need for automation, along with increased acceptance of remote tools for troubleshooting, maintenance, and factory acceptance testing (FAT), says Goodman. While he notes Cama Group has offered varying levels of augmented reality (AR) and Industry 4.0 solutions for several years, the pandemic has elevated this technology from a novelty to a necessity.

Courtesy of Cama Group

“COVID-19 is the driver of the good, the bad, and the ugly,” says Hoskins. “This is causing the demand increases that we are seeing, but has also created the issues we are seeing in supply chain. Couple that with the issues caused in running the business and keeping your employees safe, and you really have a lot of challenges to solve.” All in all, he notes, the industry has done a great job collaborating and managing expectations to keep projects successful.

“While we offer many standard, off-the-shelf robotics solutions, we are seeing a real uptick in requests that are highly customized,” says Hoskins. Projects once considered too expensive because of their custom nature are now getting the green light because of the current labor issues. The primary driver of the increased demand right now is the necessity to reduce labor to reduce our customers’ risks, he says.

“There is a recognition that something needs to change,” says Akavia. “The market is extremely competitive, and only getting more saturated and competitive with time. That makes it increasingly difficult to edge out the competition. At the same time, consumer expectations are also getting progressively higher. People expect an excellent product every single time, and they expect that product to be available every time they go to the store or shop online. When their expectations aren’t met, consumers are quick to simply go for the next brand.”

This means snack and bakery manufacturers are investing a lot of thought, effort, and resources on new ways to meet demand and consumer expectations in a scalable way, says Akavia. “It’s clear that automation and other AI-related technologies are the way forward, but baked goods manufacturers are often unsure where to start.”

A key challenge is how to improve production efficiency at a time when it is very difficult to find enough people to staff existing production lines, says Akavia. “The role of AI is to bridge that gap—to take an ‘ordinary’ production team, with all its limitations, and enable that team to perform exceptionally. We’ve seen an unprecedented wave of demand over the past year and a half, with so many leading manufacturers turning to Seebo to solve precisely this challenge. I think there’s a clear understanding out there that the early bird catches the worm: Those manufacturers who get ahead of the game will gain a serious competitive advantage in the coming years.”

The robots are coming

The pandemic created a need for social distancing amidst an ongoing labor shortage. Industrial robots and cobots have, in many cases, allowed for the addition of shifts to increase throughput while allowing for social distancing and sanitation, says Elkins.

Yaskawa offers high-speed delta (models MPP3 and MPP3S), as well as SCARA (models SG400 and SG650) robots, which can be used in applications like sortation, tray loading, or the manipulation of product into flow wrappers, says Elkins. For secondary packaging front, Yaskawa’s HC10DT and HC10XP collaborative robots, or the GP4, GP7, GP8, GP12, and GP25 models, are suited to tray packing and case packing applications, he says. “All the delta, GP- and HC-series robots are available with food-grade grease.” Yaskawa’s new HC20XP and PL-series palletizing robots can be utilized for end-of-line palletizing of trays or cases.

Robotic operations and cobots continue to bring a wider range of solutions to bakery processes. Riis notes Apex Motion Control offers standard and custom solutions for most production applications, including:

- BAKER-BOT, a versatile cobot that easily integrates with most production systems and is very easy to use, notes Riis. It helps reduce or remove tasks associated with repetitive strain. It’s used for tray handling, such as loading and unloading trays from bakery racks and conveyors; palletizing and primary or secondary pick-and-place applications; robotic decorating or spraying; and depositing or filling.

- DECO-BOT, an all-in-one robotic decorating, drizzling and writing system with built-in conveyor and controls that integrates into production conveyors or as a standalone system. It features and automated rose decorator featuring two color decorating heads/nozzles and capabilities to run cupcakes in 6 or 12 pack configurations at 20 cycles a minute, and writing or drizzling at 6 inches per second, with quick tooling and nozzle changeovers. It can help reduce incidence of personnel repetitive strain injury and helps with skilled labor shortages.

- SMART CONVEYORS are standard or custom conveyors purposely designed for pre- and post-bake bakery production, in straight, inclined, multi-directional, and/or multi-level, with break-away points on the conveyor if used in limited spaces and solutions for any production scenario and footprint. A cake-layering conveyor automatically stacks iced layers of cake as they move down the conveyor line to be iced and decorated.

Courtesy of Apex Motion Control

“As we like to say with our Baker-Bot cobot, it’s happy doing dull, dangerous, and dirty jobs,” says Riis. It removes repetitive tasks such as moving products or trays from one place to another, or decorating cakes, cupcakes, and cookies, he notes. They have a very small footprint and can safely work alongside humans.

“We don’t believe that robotics and automation will or should eliminate the need for manual labor, but there needs to be a precise balance between the two so that that dependency on filling those manual-labor positions lessens—especially when the manual labor pool is shrinking,” says Riis.

Schmitt notes Staubli’s TS2 SCARA series robots, with a reach of 40 to 100 cm, can now go in hygienic and sensitive environments. He also recommends Hygienic Environment (HE) six-axis robots for primary handling and washdown areas. The HE version of the TX2 series for sensitive food applications that require fast kinematics can withstand washdown and temperature changes, he notes. The six-axis robots are used for decorating, unloading cakes from oven trays, handling/transfer of cake bases or trays, etc., he says.

Supporting roles

Cama Group’s existing AR technologies have proved essential over the last 18 months, says Goodman. “We have seen vast amounts of remote interactions between our factory in Italy and customers all over the globe, ensuring quicker commissioning and testing during installs and maximum uptime during operation.”

Greater need often catalyzes greater opportunities for innovation. “We are finding new, interesting, and useful ways to exploit AR’s capabilities to offer even greater service to our customers,” says Goodman.

An Augmented Machine Assistance Package on BreakThrough Generation (BTG) machines provides immersive, line-side support for warranty, spare parts, and consumables, notes Goodman. “Cama’s AR support not only helps ensure maximum uptime, it also simplifies the spare parts process through a single point of contact.”

Motors underpin many automation tasks. Laurie Andres, marketing manager, NORD, Waunakee, WI, notes NORD offers highly efficient motors, including:

- IE5+ Synchronous Motors, with the high operational efficiency available. It features a reduction of variation through constant torque over a wide speed range. A non-ventilated (N-Design) option works in hygienic washdown areas, while the ventilated variant (F-Design) has high overload capacity.

- DuoDrive Integrated Gear Motor, with extremely high system efficiency (up to 92 percent). It features a compact, smooth, washdown design, and quiet operation.