Ovens, proofers, dryers, & fryers

PROCESSING

The BOTTOM LINE

- Features and benefits of equipment are important

- Digitalization is key

- New technology

Snack and bakery companies looking to purchase new or improved ovens, proofers, fryers, and dryers have a long list of requests when it comes to features and benefits, according to manufacturers of those types of equipment.

Those include: sanitation, accessibility, consistency, reliability, comprehensiveness, higher capacity, digitalization, energy efficiency, waste reduction, and greater interest in baked snacks, kettle and tortilla chips, and the use of locally sourced ingredients.

Reliable and efficient

Customers of ovens, proofers, dryers, and fryers look for benefits like sanitation, digitalization, and others.

Ed Finkel, Contributing Writer

Field reports

Bühler Group’s biscuit division, based in Copenhagen, Denmark, has experienced increased demand for baked snacks, says Amaury de Ricqlès, head of business development for biscuits. In addition, customers are requesting the use of healthy, sustainable, and more locally available ingredients.

Customers of AMF Bakery Systems, Richmond, Virginia, have been asking for greater energy efficiency and the use of alternative fuels to bring that about, says Philip Domeniucci, baking system specialist. “We’re doing analyses of that and what we can bring to the market to reduce the amount of energy they’re using,” he says.

Resource-saving manufacturing processes, ideally combined with digitization, are top of mind for customers of Koenig Bakery Systems, Ashland, VA, according to Richard Breeswine, president and CEO.

Courtesy of Heat and Control

The company also has seen a greater demand for higher-quality, more nutrition-focused products, he says.

Banner-Day, Saginaw, MI, regularly hears from customers who want to improve the reliability of their production processes, says Mike Day, president. This requires the ability to eliminate both lost product and greater labor expenses due to nuisance electrical power interruptions, he says.

Customers of Heat and Control, Hayward, CA, want higher capacity, in part due to greater demand for snacks, as people have been working from home during COVID and noshing more regularly. Greater interest in kettle chips, and potato chips more generally, has been part of that trend, says Don Giles, director of sales, processing systems. And the company has noticed higher popularity of both vacuum fried snacks and high-protein, multi-grain snack chips.

“They want to go into limited production on new production, small runs with quick changeovers.”

— Teri Johnson, vice president, TNA North America

Courtesy of tna

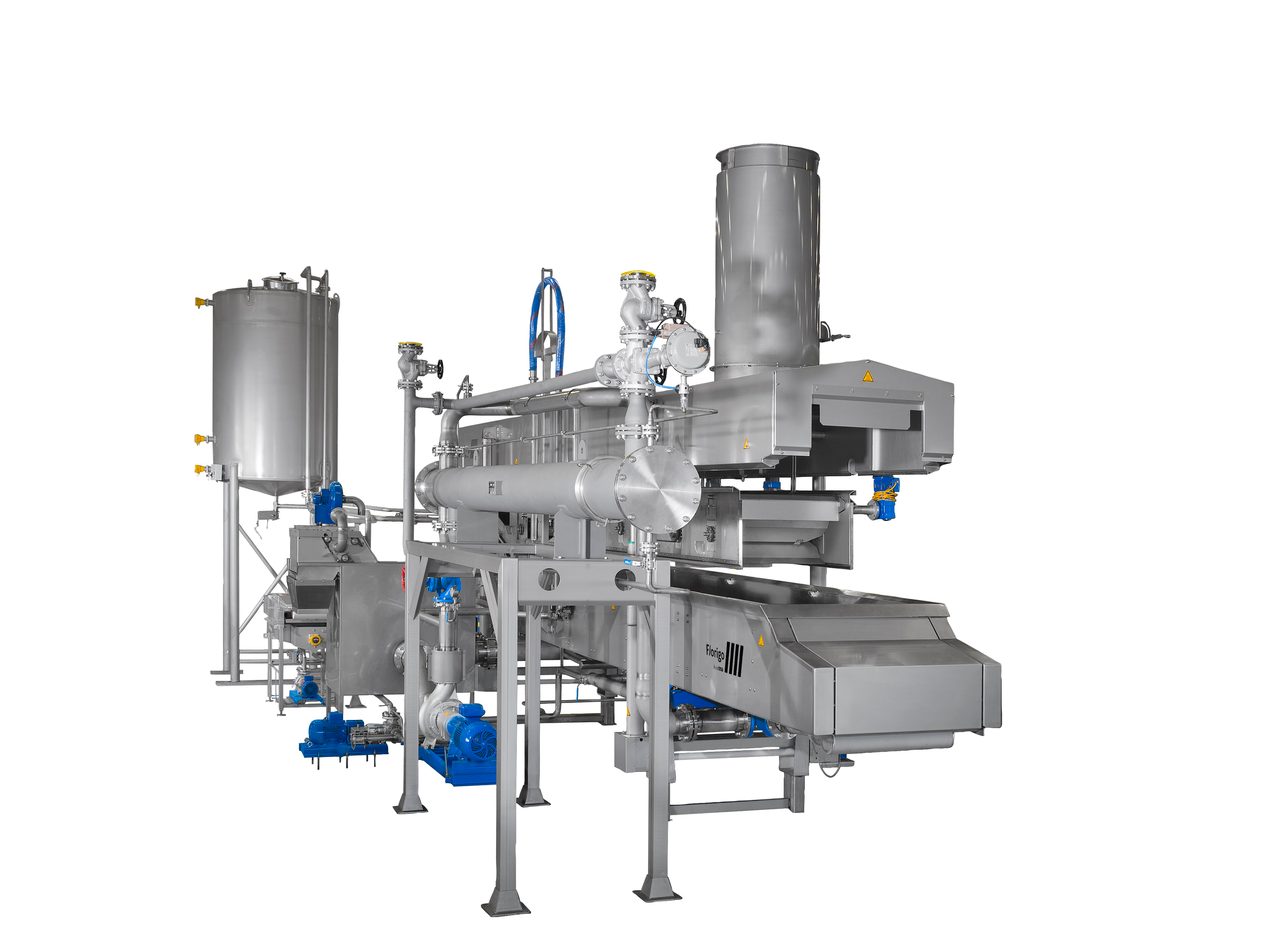

Complete systems that handle raw product through the fryer and then into seasoning, packaging and distribution have been top of mind for customers of TNA North America, Coppell, TX, says Daniel Luna, processing solution specialist. “They’re looking for one source to do the complete line for them,” he says. Luna also has heard more requests for both stainless steel construction and further automation. “They’re asking us to add more sensors, more reliable sensors,” he adds. “Limited production runs drive the demands.”

Teri Johnson, vice president, TNA North America, cites heavy demand for both tortilla chips and pork rinds. And she says that the many co-packers the company works with need flexibility and automation. “They have high turnover. They can’t get a lot of skilled workers,” she says. “We’re seeing demands for new or refresher training for employees. They want to go into limited production on new production, small runs with quick changeovers.”

G&F Systems, Inc., Roosevelt, NY, receives regular requests for greater sanitation and accessibility, as well as proofer air-handling equipment that uses both dry heat and cooling coils, as opposed to a purge fan, says Anthony Salsone, vice president, sales & engineering.

“Bakers want to maintain proofer consistency—very tight, dry heat and absolute humidity bands along with mitigating stratification inside the proofer,” he says. “This has led to new energy and environmental opportunities, such as industrial heat pumps to make use of the excess waste heat in the proofer to produce chilled water for the cooling—creating a closed-loop energy system—which is a big score for sustainability objectives.”

Courtesy of G&F Systems

New and improved

The biscuit division of Bühler is among those that have rolled out new or improved ovens in the past year or so, expanding its portfolio in the baked snacks market. The company has two new complete process lines, one for baked, fabricated chips, and the other for extruded pretzels, de Ricqlès says.

The fabricated chips line can be supplied with a continuous mixing system and includes forming, baking, drying and post-seasoning solutions from Bühler Group, creating a one-stop shop for the customer, he says.

The pretzel line extrudes at 300 strokes per minute, faster than the market standard, de Ricqlès says. The machine also offers gentle handling of breads and doughs. “We don’t stress the dough,” he says.

“Our ovens are also first-in-class in energy consumption. The design of our convection oven, using the drying section, is compact and efficient.”

AMF Bakery Systems has a couple of new oven products as well. The company is in the process of rolling out the hydrogen-fired Multi-Bake Vita open, which has U.S. and international patents pending related to its burner design, and which provides a combination hydrogen/natural gas burner that can use one or the other, or a blend, Domeniucci says.

“We have found that by mixing a specific amount of hydrogen, we can reduce the carbon footprint by 25 percent,” he says. “Moving forward, with the potential elimination of fossil fuels, we don’t have a lot of choices other than electric—and I think [finding enough capacity for] electric is going to be a challenge if you take all automobiles and change them to electric.”

Secondly, AMF has released Smart Oven technology aimed to increase production efficiency and energy savings by uploading real-time data to the cloud, where end users can do real-time analyses and report them back to the plant. Not released in the U.S. just yet, the Smart Oven app looks at how much energy is released through evaporation and dissipation, how much rises up the chimney, and how much actually goes into heating the product, Domeniucci says.

Courtesy of Koenig Baking Systems

Koenig has released the latest models of both the Roto Passat SE and Passat OH ovens, which are the smallest on the market and offer an “extremely long service life,” Breeswine says. “An innovative, user-friendly control panel enables intuitive operation of the oven, and with the ‘Smart Connect’ package, several ovens can be networked with one another and conveniently controlled from the office.”

The latest models also offers greater energy efficiency, Breeswine says. The company has done so with several upgrades, including “a flow-optimized heating coil, high-quality sandwich insulation with an aluminum intermediate layer, a continuously adjustable steam and control system, and the double-walled baking door make of Duplex steel, with real ventilation for low surface temperatures.”

G&F Systems offers custom-designed and manufactured “turn-key” spiral proofing environmental systems, Salsone says. “Our typical design houses all of the proofing equipment, in self-contained single or double stainless-steel towers, which are located either inside or outside of the proofing enclosure,” he says. “This linear arrangement of the proofing equipment offers multiple benefits, including reduced footprint, ease of maintenance and [improved] sanitation.”

G&F has partnered with Air Management Technologies to strategically design systems with improved sanitary design of interior and exterior ductwork, Salsone says. “Our current design focus revolves around sanitation and ways to improve accessibility inside the proofer closure,” he says. “Additional innovations have been on distribution devices, which require less space, improving maintenance accessibility inside the proofer enclosure where ductwork often protrudes into the space.”

Banner-Day has reintroduced a product called PIP—Power Interruption Protection, which guards against nuisance short duration interruptions of power supply to ovens and proofers. “These events create costly and challenging disruptions,” Day says. “Oven purge is lost, and consequently must be re-purged prior to relighting. In many instances, oven purge can take upwards of 10 to 15 minutes. When having to purge and relight the oven, product in the oven is often lost, as well as product in the proofer.”