Robotics & automation

packaging

The BOTTOM LINE

- Challenges to manufacturers

- Robot design costs

- Pandemic hygiene standards

New robotic technology is helping to streamline and improve bakery and snack operations in both primary and secondary packaging applications. Areas of innovation include end-of-arm tooling (EOAT), sanitation, and space optimization. Gripper technology also is advancing to handle delicate products such as soft bakery items.

On the move

New systems improve packaging operations in bakery and snack plants.

Neal Lorenzi, Contributing Writer

However, the nature of bakery and snack plants poses many challenges to manufacturers. One challenge is the wide variety of production options, ranging from large tunnel oven systems to smaller rack oven systems. A one-size-fits-all approach won’t work in these situations. “You need a diverse robotic platform to automate these wide-ranging production systems,” says Dave Wood, product manager at Syntegon Packaging Technology, New Richmond, WI. “That’s why Syntegon offers a modular approach to robotics.”

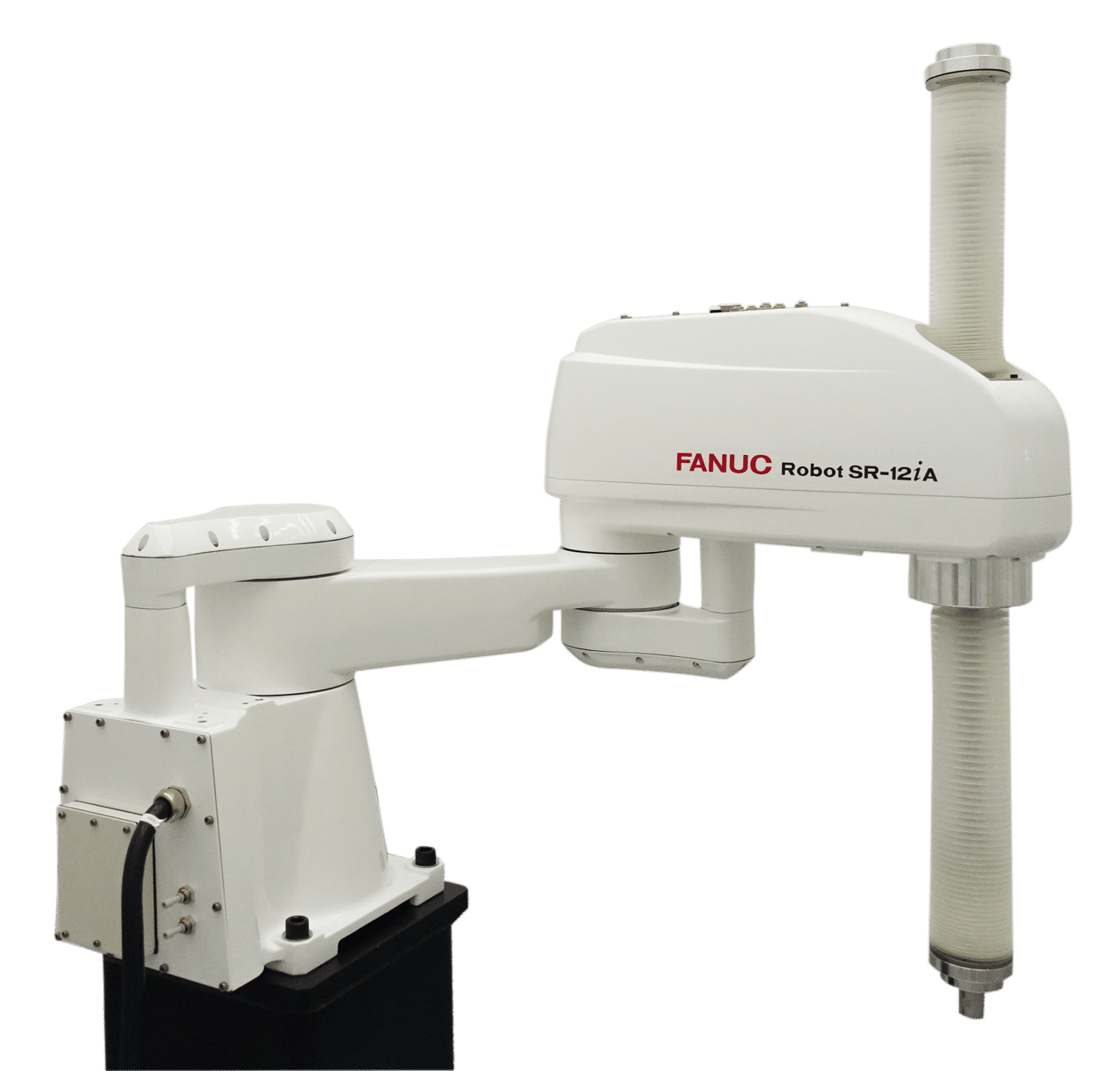

Also, robotic food adaptations add additional costs to a robot’s design, according to Wes Garrett, senior account manager, FANUC America Corp., Rochester Hills, MI. “A manufacture may prefer a full stainless robot design; however, the return on investment (ROI) may not allow for justification of the project. There has to be a balance of what is nice to have and what is absolutely necessary.”

Advances in technology

Robots designed for flexibility are crucial in bakery and snack production, according to Maria Ferrante, senior director, marketing and communications for PMMI, Herndon, VA. “Robots with pick-and place capabilities that handle secondary packaging are now designed with the speed and flexibility to support shelf-ready and retail-ready packaging. In addition, pick-and-place robots can help ensure high hygienic standards, which have been accelerated by the pandemic.”

Gripper technology also is advancing to handle delicate products such as soft bakery items. All these advances make robots more versatile and adaptable to specific production needs. “The flexibility with EOAT has helped changeover times. You don’t need to change out the entire robot, just change the end effectors and a do a little programming,” Ferrante says.

EOAT is especially important when considering baked goods, according to John Weddleton, product manager of automation at Harpak-ULMA, Taunton, MA. “A traditional vacuum-based gripping tool is not suitable for all products. Pastries, for example, are typically delicate, flaky, and are often coated in either a powder, glaze, or icing—a combination of characteristics not ideal for a suction cup gripping tool.” He notes that new gripping tools have been specifically designed to handle such fragile food items at high speeds.

“Pick-and-place robots can help ensure high hygienic standards, which have been accelerated by the pandemic.”

— Maria Ferrante, senior director, marketing and communications, PMMI

Soft Robotics Inc., Bedford, MA, is at the forefront of this trend. The company recently upgraded its mGrip Modular Gripping System with new capabilities and an IP69K rating to enable safe food handling. “These new features put more capabilities into the hands of machine builders to design flexible EOAT that can withstand high-pressure wash downs,” says Julie Collura, director of marketing communications. Soft Robotics collaborates with both robot manufacturers and end users.

Courtesy of Soft Robotics

Also, mGrip’s increased adaptability allows bakery and snack producers to handle challenging products on virtually any type of robot; one gripper can be used to pick multiple SKUs. “New, compact finger modules enable tighter grip spacing (down to 20mm) to improve picking performance for smaller items. These smaller, lighter finger modules result in lower-mass tools, which improve product handling, permit faster rates and cause less system wear over time,” Collura adds.

Advances in 3D printing have brought forth the ability to form very complex manipulators at the end of the robot arm. As this technology becomes more affordable, it is being deployed in many new areas, according to Ferrante. “Robots also are becoming smaller, more compact and therefore more affordable. They have gone from big dedicated lines to small and lightweight modules that can be moved around.”

The development of compact, articulated robots such as the Motoman GP4 allows for greater flexibility in the way that items, such as cookies, crackers and flow-wrapped products, can be presented to the robot for manipulation, according to Dean Elkins, segment leader, handling for Yaskawa Motoman, Miamisburg, OH. “Also, the robot’s IP67 construction and incorporation of food-grade grease make it easier to use in sanitary applications.

“Some cooperative robots (cobots), such as the Motoman HC10XP, feature a streamlined design, enabling them to be integrated into areas where standard industrial robots cannot work as effectively due to their need for safeguarding,” Elkins adds. “Also, the HC10XP features an IP67 construction and food-grade grease.”

Courtesy of Yaskawa Motoman

When calculating the ROI of robotics, it is important to consider factors such as labor, floor space requirements, maintenance costs, overall equipment effectiveness, and changeover time, notes Elkins. A calculator on the Association for Advancing Automation website can help determine ROI (see “ROI Robot System Value Calculator”).

Breaking innovations

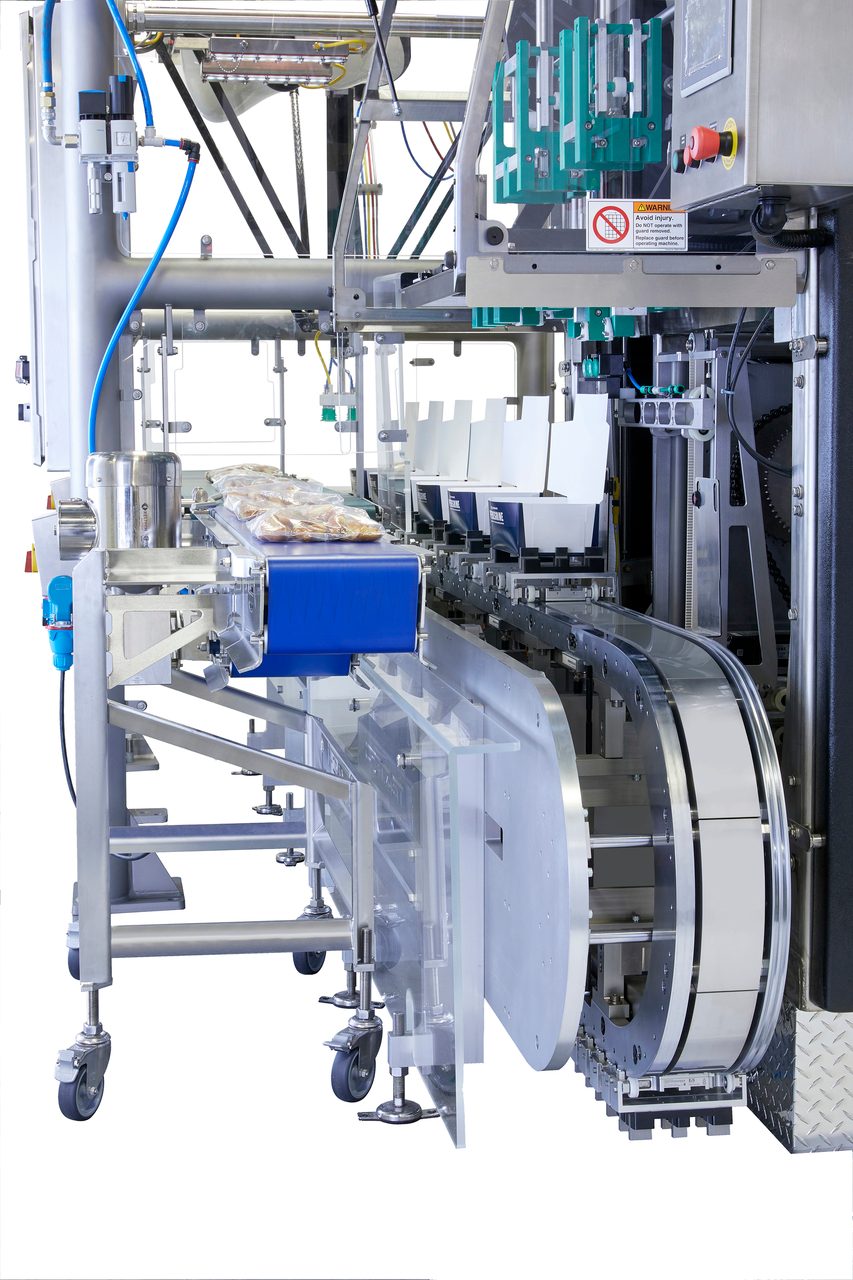

New packaging equipment that incorporates robotics offers many of the aforementioned flexibility, hygienic, and space-saving features. JLS Automation, York, PA, has introduced the Peregrine Carton Loading and Closing Machine, which enables full carton control from forming through closing, without turns or conveyors, at high speeds. “The JLS TRAK, a high-speed carton management system, combined with the Peregrine’s positive carton transport (PCT) system, keeps the machine small and compact,” says Craig Souser, president and CEO.

Once cartons are loaded, the JLS TRAK moves down the line where a vision-guided robot simultaneously closes the carton, picks it up and places it on a discharge conveyor where it is sent downstream. “The Peregrine streamlines the process and eliminates the need for carton plows, tucker wheels and additional conveyors,” Souser notes.

Courtesy of JLS Automation

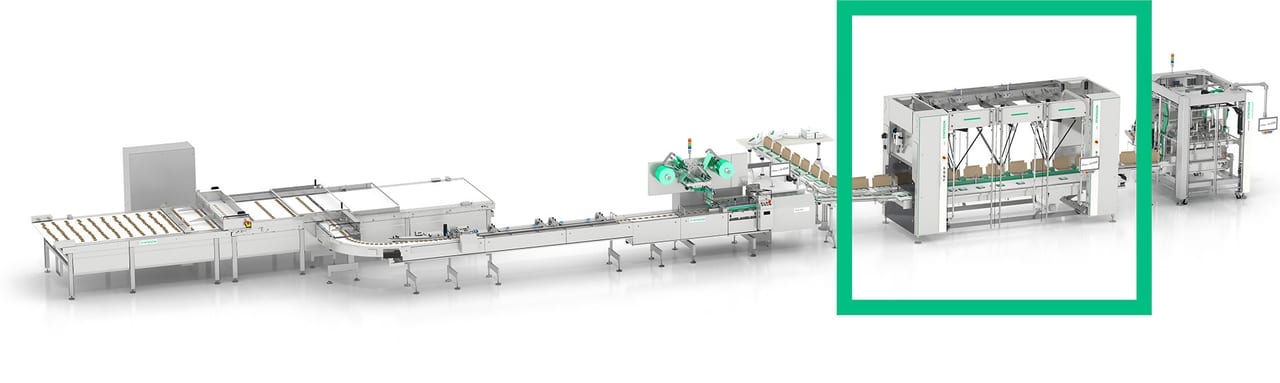

Syntegon Packaging Technology has introduced the RPP (robotic pick-and-place) platform, which is modular and allows bakery and snack producers to upgrade automation with simple add-on modules as production needs increase. Delta robots can be flexibly connected and, together with transport modules, seamlessly integrated into an overall system. RPP cells provide good visibility, easy access to products and efficient cleaning, the company reports.

Courtesy of Syntegon

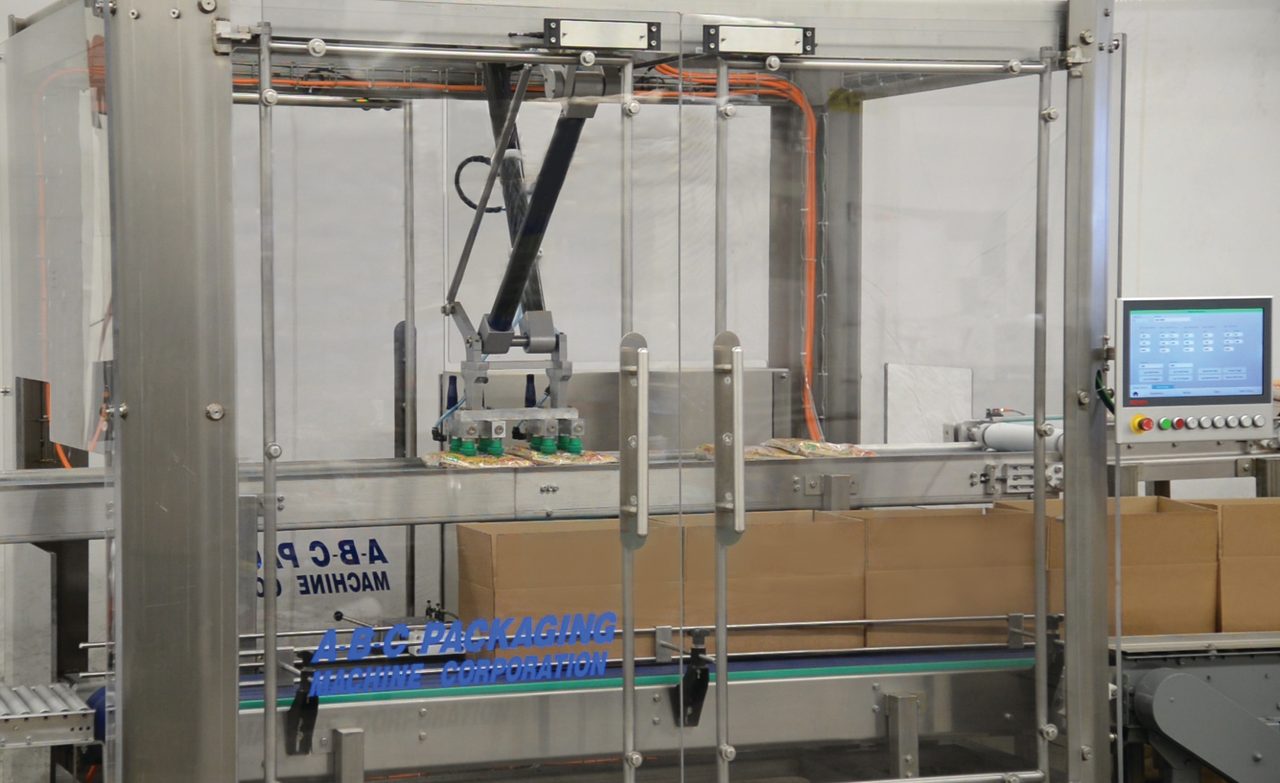

A-B-C Packaging Machine Corp., Tarpon Springs, FL, offers the M600 robotic packer, which offers many benefits for bakery and snack producers, according to Bryan Sinicrope, vice president of marketing and integrator sales. “The gentle handling of this packer is a key benefit for delicate bakery and snacks as products are gripped, transferred and packed with careful precision. For higher volume, we can pack multiple cases or trays at once, which multiply the line volume while maintaining a constant speed with smooth, gentle product handling.”

Another advantage is flexibility, Sinicrope adds. “The M600 can pack cartons, semi-rigid containers, flexible packages, bags, cups or multipacks. It is easily changed to pack different patterns with simple touch-screen commands. Also, new products and pack patterns can be set up at a human machine interface and grippers are easily reconfigured.”

Courtesy of A-B-C Packaging

BluePrint Automation, South Chesterfield, VA, offers the Spider 300v Packing System, which utilizes Vision Guided Delta Robots to pattern form arriving products onto a pick belt for robotic placement into cases, trays, or cartons either in a vertical or horizontal pack pattern. The system allows for random product arrival at high speeds and provides flexibility in packaging formats.

“Low product count and single-file presentation of shelf-ready display cases usually requires a large labor force to maintain minimum plant efficiency,” says Jason Hogue, Southeast sales manager. “The Spider 300v can run up to 50 display cases per minute, improving plant efficiency without a large labor burden.”

Yaskawa Motoman has introduced the GP-series robots, which are well suited for primary and secondary packaging operations, according to Elkin. “Our new SG400 and SG650 SCARA (selective compliance articulated robot arm) robots offer a space-saving design for packaging tasks. Coupled with optional 2D or 3D vision systems, they can work in lights-out (no human presence) operations cost effectively.” In addition, Yaskawa material handling robots give programmers the option of affecting robot motion through a series of easy add-on instructions.

Courtesy of BluePrint Automation