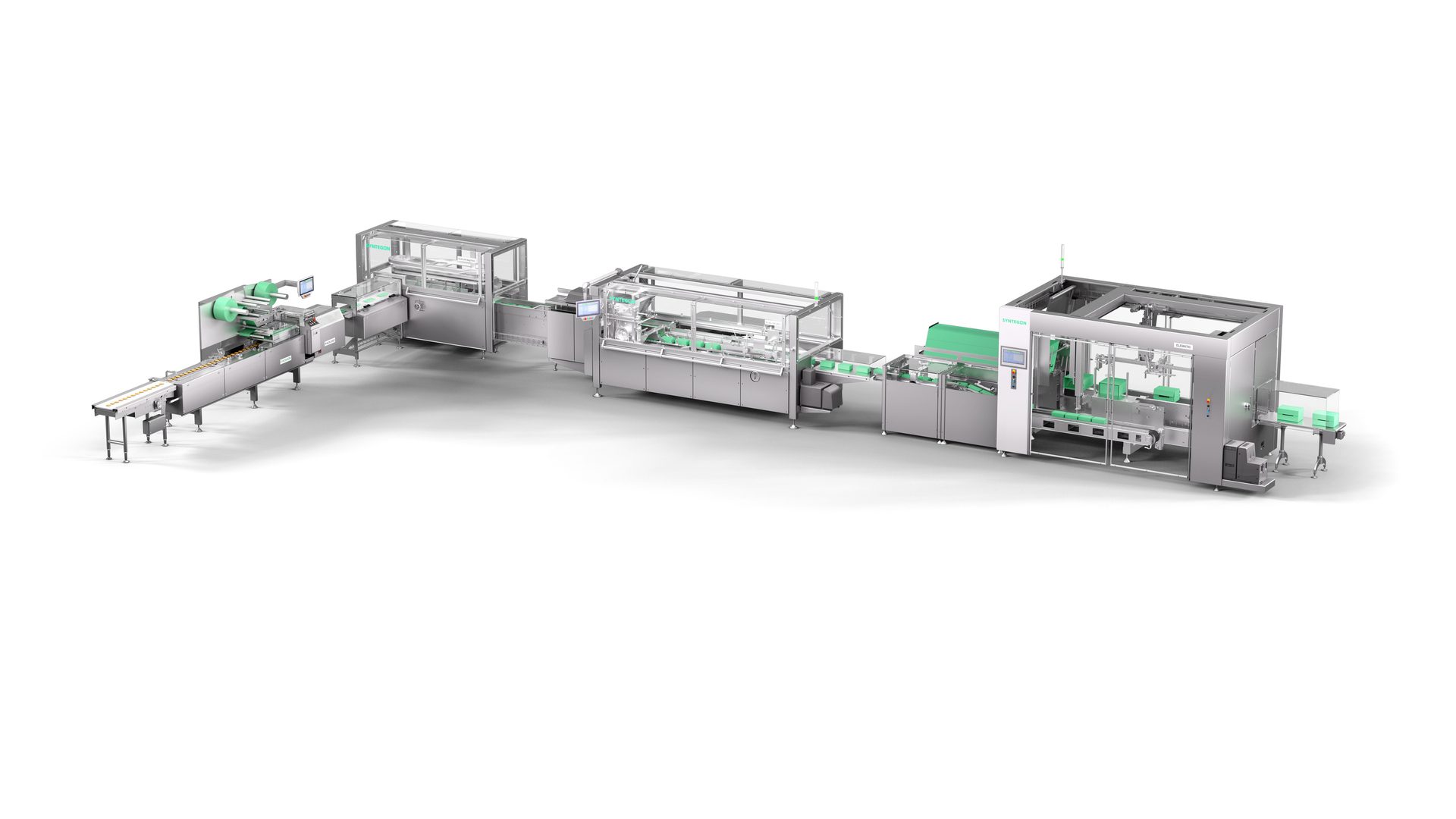

Bakery packaging equipment

Tech & Techniques

The BOTTOM LINE

- Flexibility is high on the list of priorities when shopping for tech

- Gentle product handling is desirable, especially for delicate bakery products

- Advances in automation are good news for equipment specifiers

Turning it around

Quick changeovers and efficiency are top priorities for snack and bakery packaging systems.

Neal Lorenzi, Contributing Writer

When it comes to improving their packaging operations, snack and bakery producers are seeking equipment that handles multiple formats with seamless, fast changeover. Other desired capabilities include integrated automation, gentle product handling, flexible changeover and sustainability. Sanitation (via hygienic, open-frame construction) is another. Sustainability also has become a key driver, with many producers wanting to reduce the use of corrugated materials.

Delivering innovations

In response, equipment vendors now offer equipment that features automated changeover mechanisms to eliminate manual adjustment and minimize downtime. Some offer complete, modular solutions that integrate forming, loading and closing within a single system. Robotics is playing a transformative role, especially in case and tray packing. Collaborative robots (cobots) also play a growing role—particularly in bakeries with limited floor space.

Courtesy of Formost Fuji

Courtesy of Somic Packaging, Inc.

Commitment to innovative training programs also is important. Formost Fuji offers onsite training as well as customized in-person classes at its factory, designed to match customers’ needs and skill levels. Heat and Control has created E-Learning tools that include tutorials to machine operation and keys to optimize efficiency.

Snack and bakery production does pose challenges to vendors. Unpredictable product shapes and conditions require designs that can adapt in real time. Another is handling delicate products at high speeds, which demands precision robotics and vision systems. Layout restrictions pose a challenge in many plants, due to lines being designed years prior to packaging automation.

Somic Packaging Inc. offers the 434 Wraparound Case Packer, which can handle wraparound cases and display trays. When paired with a cover applicator, it also runs two-piece, tray-and-cover, retail-ready packages. “Our new 434 SuperFlex elevates this capability by combining physical collation with pick-and-place versatility. This enables the creation of unique formats and customized variety packs,” says CEO Peter Fox.

Campbell Wrapper Corp. offers the eXcel high-speed flow wrapper, which can run heat seal and cold seal films. It features an easy-to-setup automatic film splicer and servo-driven film rolls for improved film tension control. “The machine has a simple design with reduced parts for ease of maintenance and numbered and directional arrows on all film rollers for easy operator thread up,” notes Mike Jarmuskiewicz, vice president of sales and marketing.

Courtesy of Campbell Wrapper Corp.

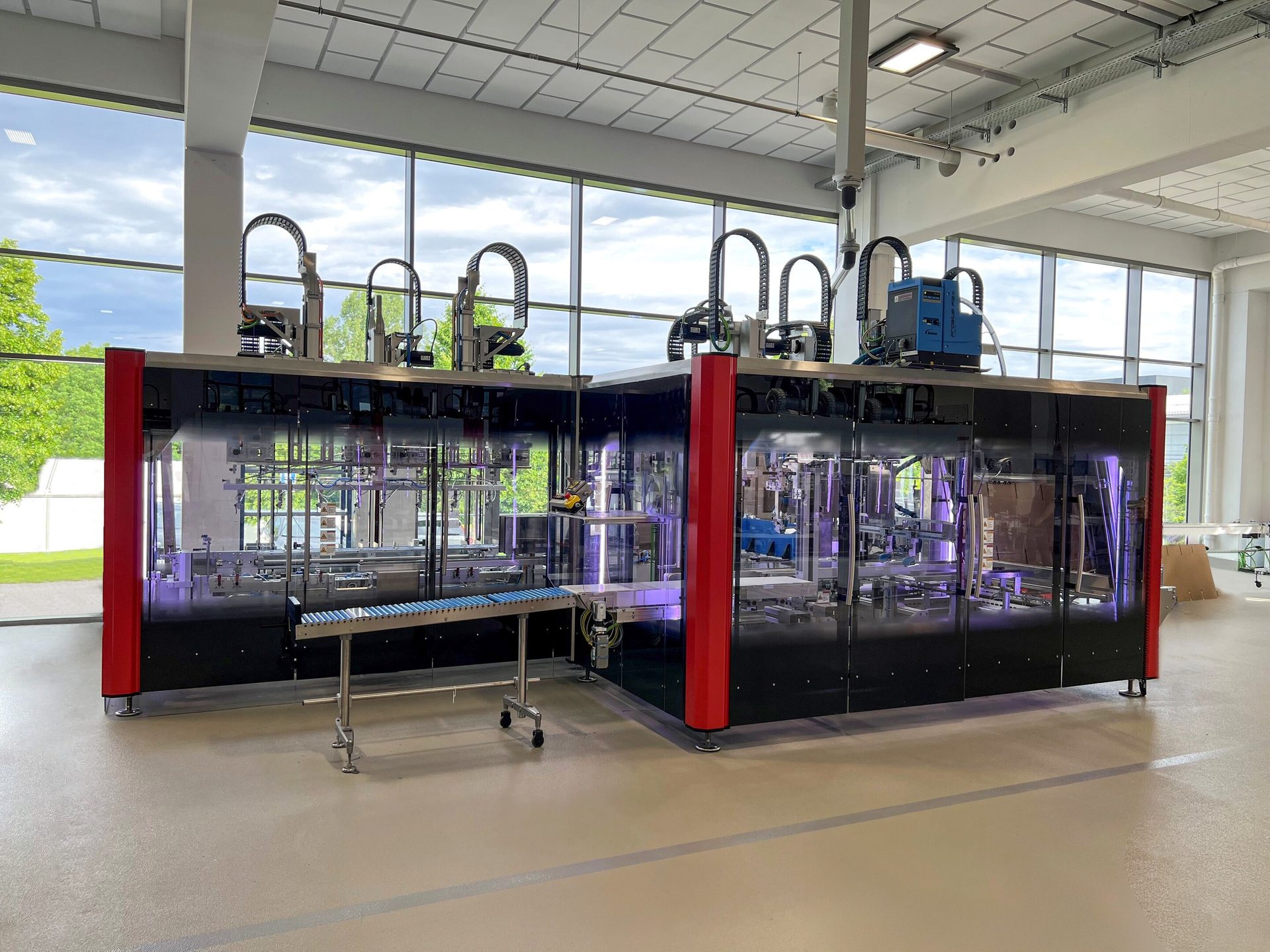

The latest advances from Cama USA center on modular systems that can be decoupled or combined in a mono-block framework to fit within small footprints. Included within these packaging machines are robots as well as carton/case conveying tracks that allow automatic centerline changes, more size capability and faster operation. “Our Model IF320 can process 90 cartons per minute within a small footprint. This system can be expanded to multiple modules, allowing for variety packing,” says Billy Goodman, managing director.

Courtesy of Cama USA

The new EVO Series Case Packer from Delkor Systems integrates vision-guided robotics with a six-axis gantry system, allowing multiple packages to be picked and placed per cycle with precision. It is only 25 ft. in length and 6 ft. in width (one cell configuration). “The modular EVO architecture supports expansion from one to four robotic cells, capable of packing up to 280 products per minute, including bags or pouches ranging from 2 oz. to 30 lb.,” says Kevin Weiss, vice president of operations. EVO can be paired with Delkor’s Trayfecta X Series Former, which reportedly eliminates corrugated warp by forming square cases from lower-grade corrugated materials in humid or dry environments.

Courtesy of Delkor Systems

Formost Fuji offers a range of packaging solutions for bakery and snack producers. The company’s product lineup includes the Alpha 8 series of horizontal flow wrappers, as well as multiple bagging machines. “We also design automated packaging lines customized to customers’ operational requirements. This ensures that systems are optimized for ease of use, cost-effectiveness, and budget alignment,” says Angela McDaniel, marketing coordinator.

The use of tray sealing equipment (rigid tray with a top-sealing film) is a good alternative to clamshells and offers modified atmosphere packaging (MAP) to extend shelf life, according to Josh Becker, bakery and confection segment manager at Harpak-Ulma. To that end, the company offers the entry level Mondini Cigno tray sealer and the Mondini NeuralVision (finished package inspection system) for tray sealed products. “With the tray sealer, producers can utilize MAP for potential shelf-life extensions,” Becker states.

Courtesy of Harpak-Ulma

Robotic solutions

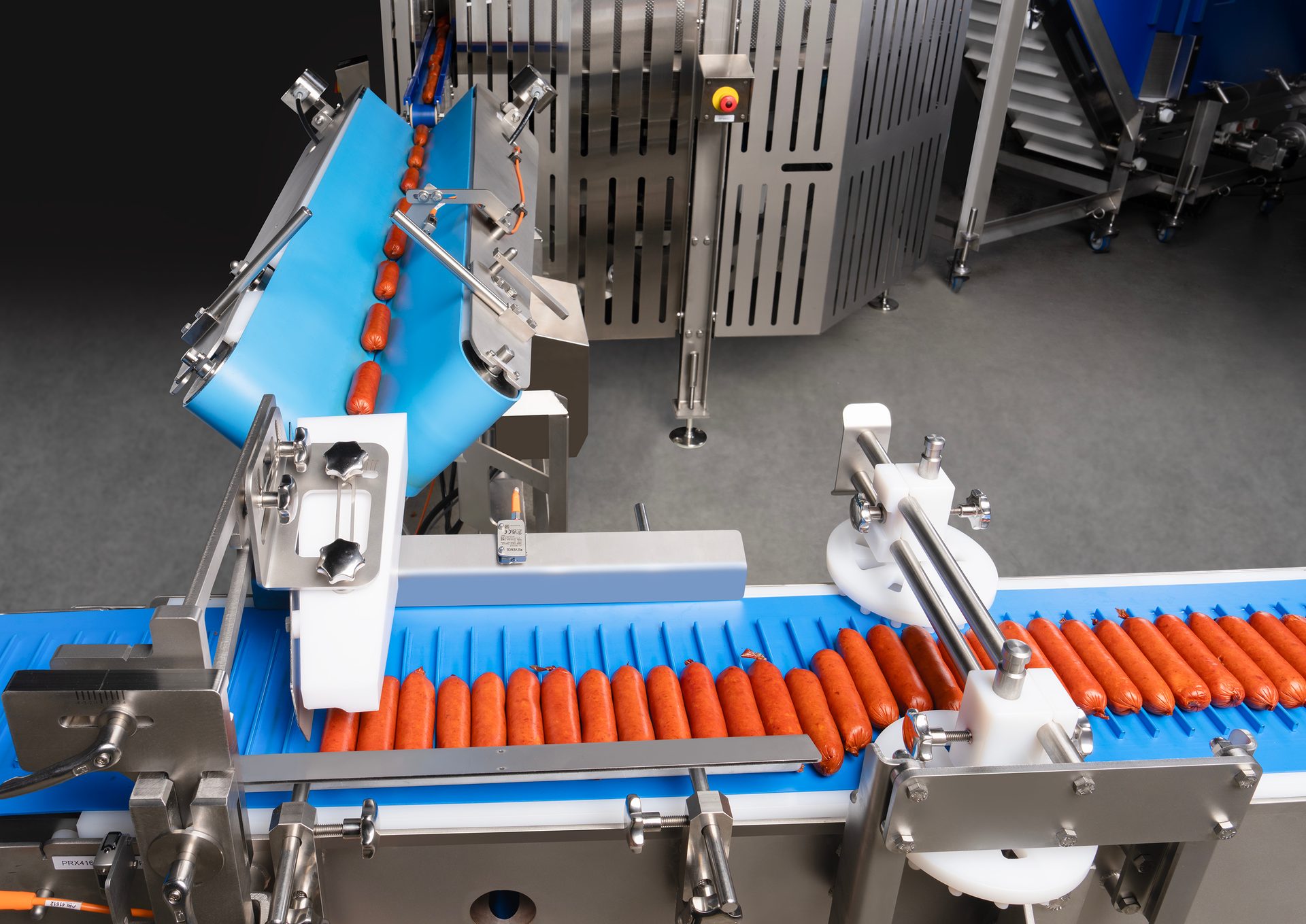

JLS Automation recently introduced robotic technology and enhanced cartoning for snack and bakery producers. The Kestrel high-speed robotic collate-and-load system helps reduce labor, maximize floor space and enhance efficiency while consolidating complex processes. “This hygienic packaging solution transforms bulk product handling into a streamlined, high-speed process and is designed to handle straight, uniform and round food products,” notes Waheed Chaudhry, director of primary packaging and integrated systems.

Courtesy of JLS Automation

JLS Automation also offers the updated Peregrine IS robotic cartoner, a vision-guided system that includes carton forming, loading and closing functions in one compact footprint. “With one control architecture for the robot and machine, it enhances operational efficiency and simplifies changeover,” Chaudhry adds.

The ACP-701 automated system from Heat and Control combines case packing, case alignment, bag packing, sorting, closing and sealing in one machine, and handles a wide range of bag sizes, case sizes and pack patterns. Case aligning and closing mechanisms are fully integrated, eliminating the need for additional conveyors. The machine can be set up in three minutes. Also, the ACP-701 is compatible with the complete Ishida product range.

The Ishida INSPIRA vertical form-fill-seal (VFFS) bagmaker from Heat and Control processes 200 bags per minute. “The redesigned machine structure is based on a study of operator behavior with reference to human engineering to improve accessibility to key components, and quick changeover with less labor required,” declares Jeff Almond, senior director, snack food industry.

Courtesy of Heat and Control

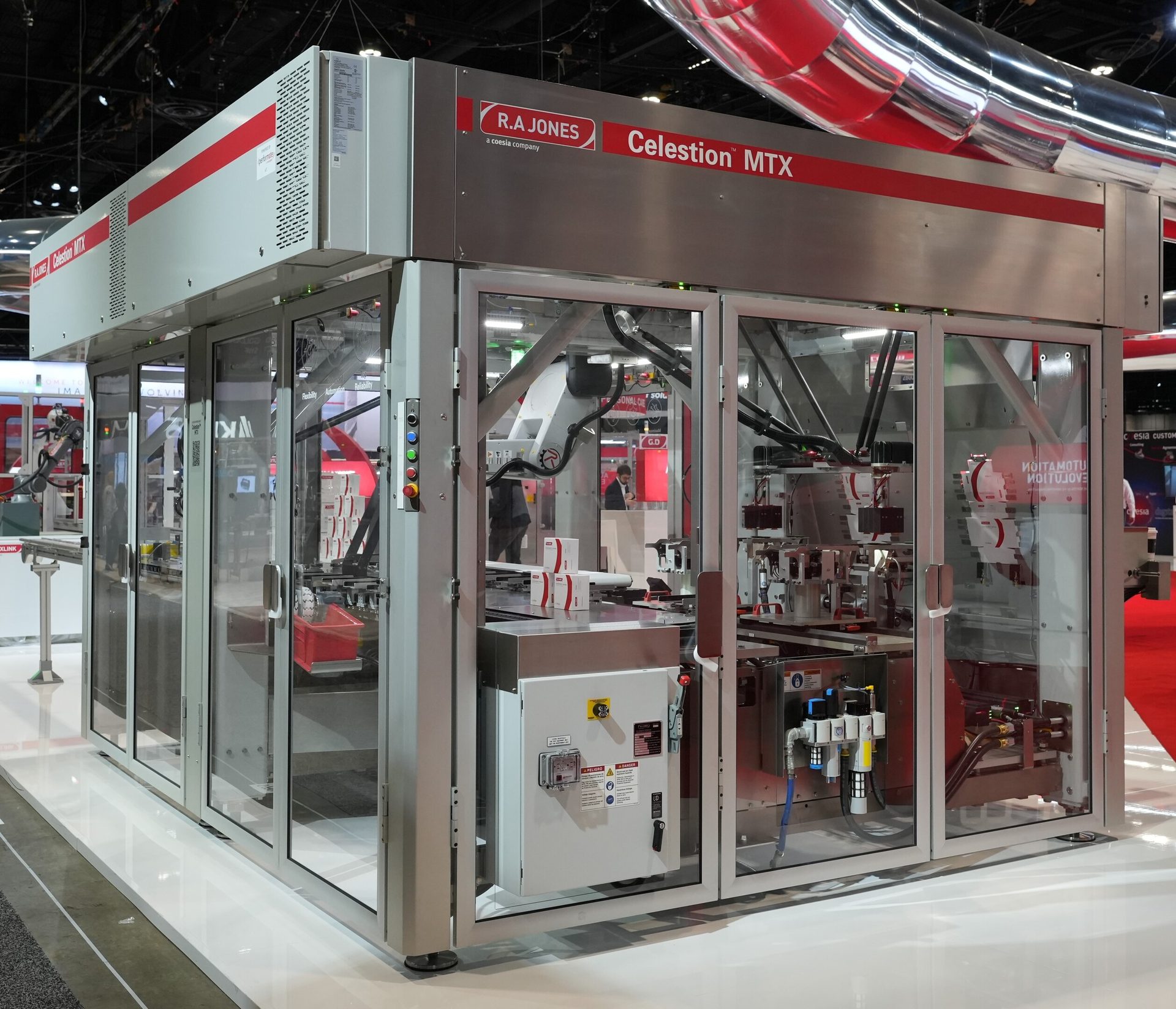

The Celestion MTX from R.A. Jones uses robotics aligned with carton/tray forming and product loading. Features include an Intelligent Carton Transport system for precise carton handling, push button changeover and modular scalability to grow with production needs, and the ability to re-deploy the machine for future product SKUs. “Worker safety and ergonomics are improved by access to both sides of the forming area for easy changeover, improving operator access for maintenance,” says Ricky Low, director of product and marketing.

Courtesy of R.A. Jones

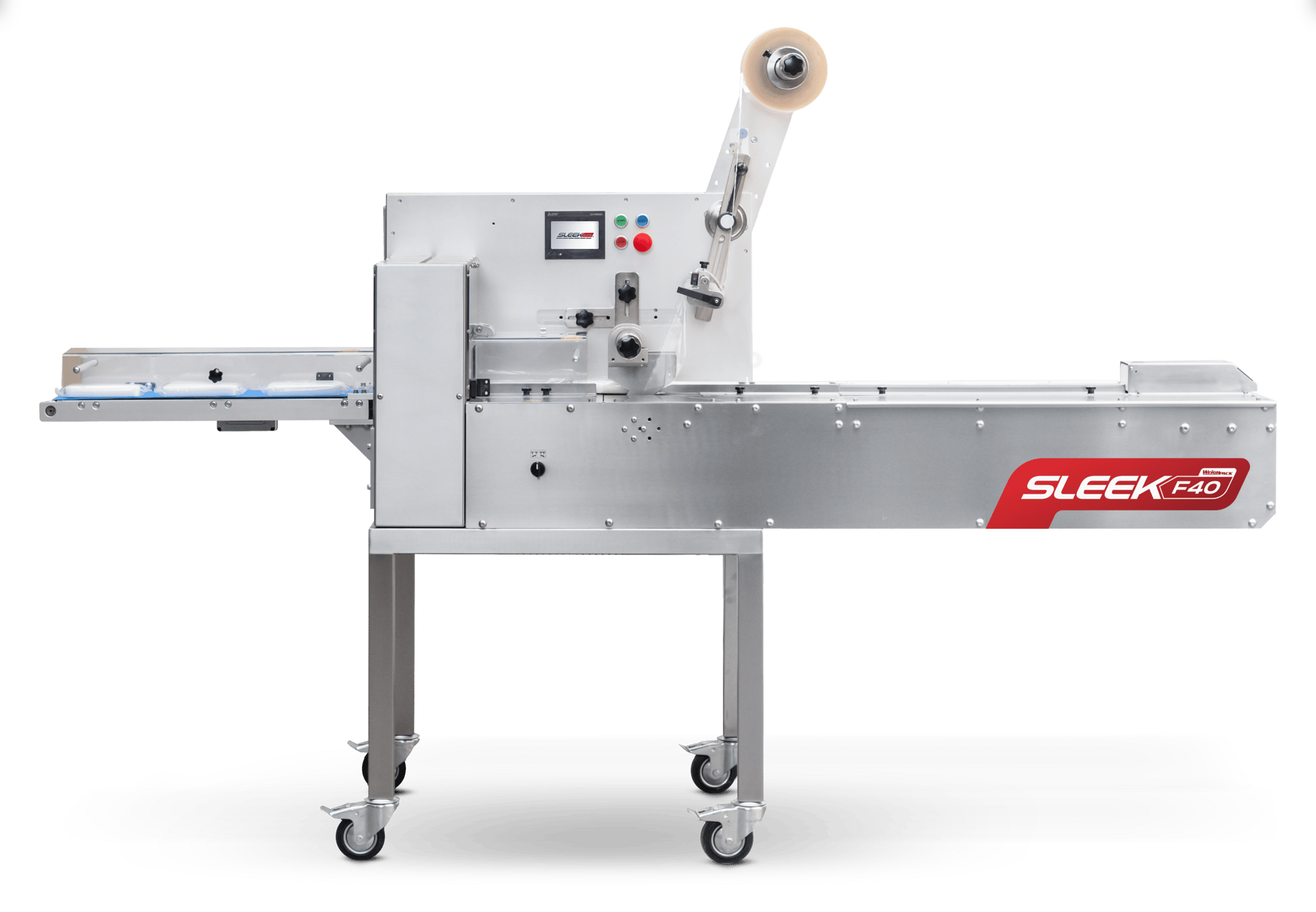

Paxiom offers the SleekWrapper F65 flow wrapper (for bars, cookies and baked snacks) with servo-driven controls and recipe-based changeovers that maintain tight registration and minimize film waste, according to Luis Pilonieta, director of sales. Also available is the VF1200 sanitary VFFS bagger, which offers auto-tuned motion and dynamic seal profiling for consistent output. The company’s new VersaPak bagger is designed to run paper-based films.

“Now, with NCC Automated Systems integrated into our portfolio, we’ve expanded into end-to-end conveying and integration services,” Pilonieta says. “By combining Paxiom’s packaging automation with NCC’s conveying and integration capabilities, we deliver a cohesive, streamlined production solution that reduces vendor handoffs, simplifies technical support and maximizes line efficiency—from product infeed through case packing and palletizing.”

Courtesy of Paxiom

Courtesy of Delkor Systems

Delkor Systems plans to introduce a new generation of Combo-line Bread Case Packers designed as an all-in-one solution for single-use shippers and reusable trays in 2025. “Producers can switch between corrugated (one way) shippers and bread tray formats in the same machine,” says Dale Andersen, president and CEO. “Retailers are moving away from direct store distribution (DSD) trays and into corrugated cases due to the challenges and costs involved.”

Delkor Systems recently introduced Smart-Lock, which streamlines packaging size adjustments using a linear bearing slide, LED-based feedback and an automatic locking system. It reportedly eliminates the need for rotary counters, allowing precise, manual adjustments with minimal effort. “It is three times faster, more accurate and designed to virtually eliminate operator errors,” Andersen notes.

“Customers want conveyor belts that can be cleaned more easily.”

— Rudy Sanchez, food handling product manager, Key Technology

Syntegon Packaging Technology’s Pack 202 horizontal flow wrapper has been enhanced with a Stacking FIT infeed module. “The module enables precise and gentle slug stacking at high speeds. This solution ensures consistent product quality, reduces breakage and minimizes waste, especially for fragile cookies and pastries,” remarks Brad Baker: senior sales director for food, Americas. Also available is Syntegon’s SVX Agile VFFS machine, which processes up to 300 bags per minute while supporting a wide variety of bag styles and recyclable films.

Courtesy of Syntegon

In addition, Syntegon recently introduced Amplified Heat Sealing technology, which reportedly combines rotary and linear sealing motions, to produce tight, reliable seals at varying speeds, even with sensitive mono-materials. Another innovation is the FGCT High-Speed Count Feeder designed for cookies. It gently groups products into precise counts and places them upright—either into trays or directly into the infeed of a flow wrapper.

Looking ahead

What packaging system innovations do vendors see in the near future? Chaudhry predicts that modular robotic packaging systems that can be reconfigured quickly to accommodate SKU variability and seasonal demand are on the horizon: “Producers will be able to adapt lines in minutes or hours, improving responsiveness and reducing downtime.”

“Smart systems that integrate sensors, vision systems and predictive maintenance will allow machines to autonomously optimize processes.”

— Peter Fox, CEO, Somic Packaging

“Manufacturers are always looking at new products, formats, and SKUs, and inspection equipment needs to be flexible enough to support that.”

— Richard Reardon, general manager, Antares Vision Group