Jon Gilchrist, applications engineering manager, KPM Analytics, Westborough, MA, says that food safety plans will vary between bakeries and typically are tuned to their specific products, customers, and regional requirements.

“Despite these differences, every food safety plan is intended to identify and reduce food safety hazards throughout the production process. A key element of this plan should include the implementation of monitoring checks at critical control points along the process,” he says.

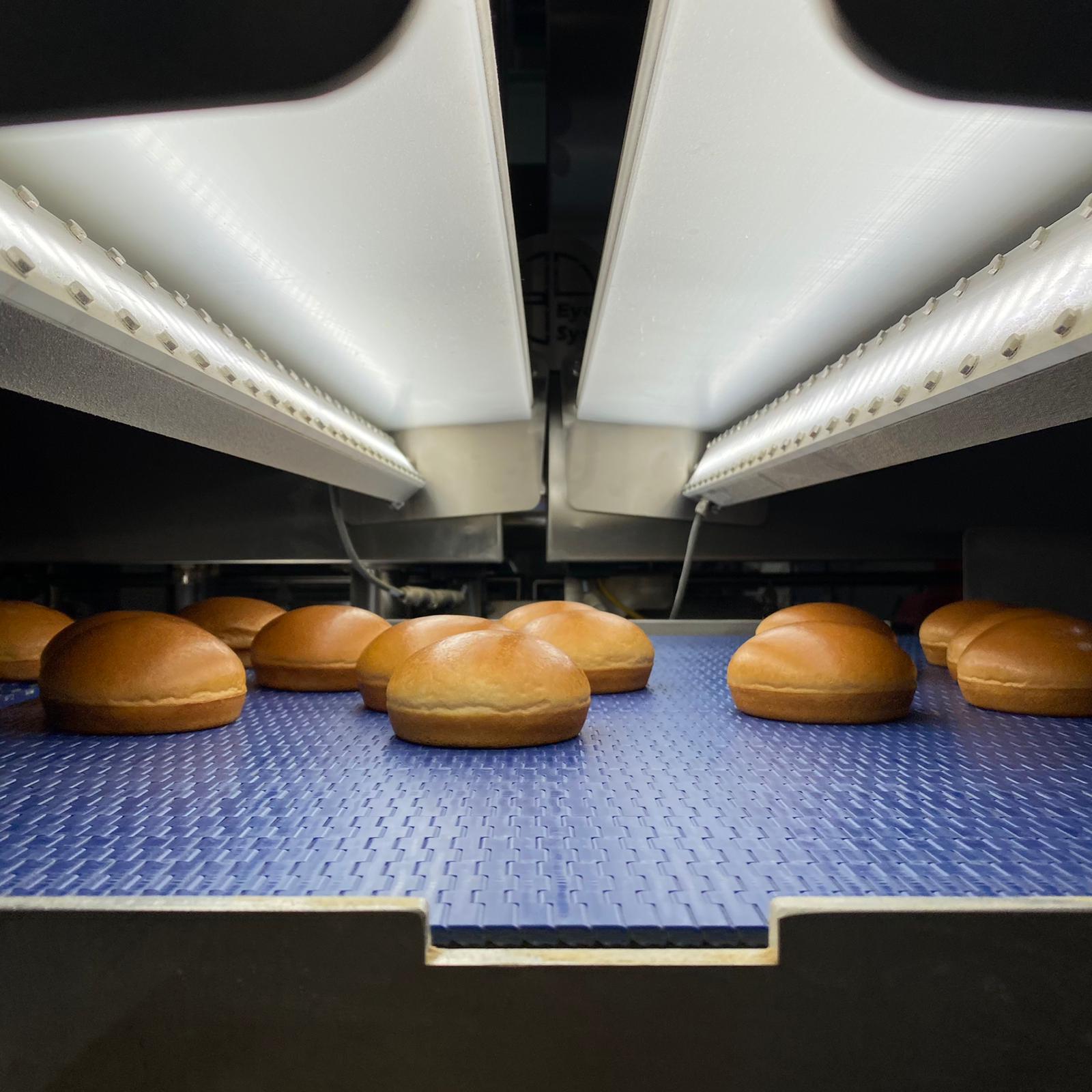

Most bakeries have adopted equipment such as metal detectors and x-ray, but bakers are increasingly turning to vision inspection systems to help fill this need, Gilchrist elaborates.

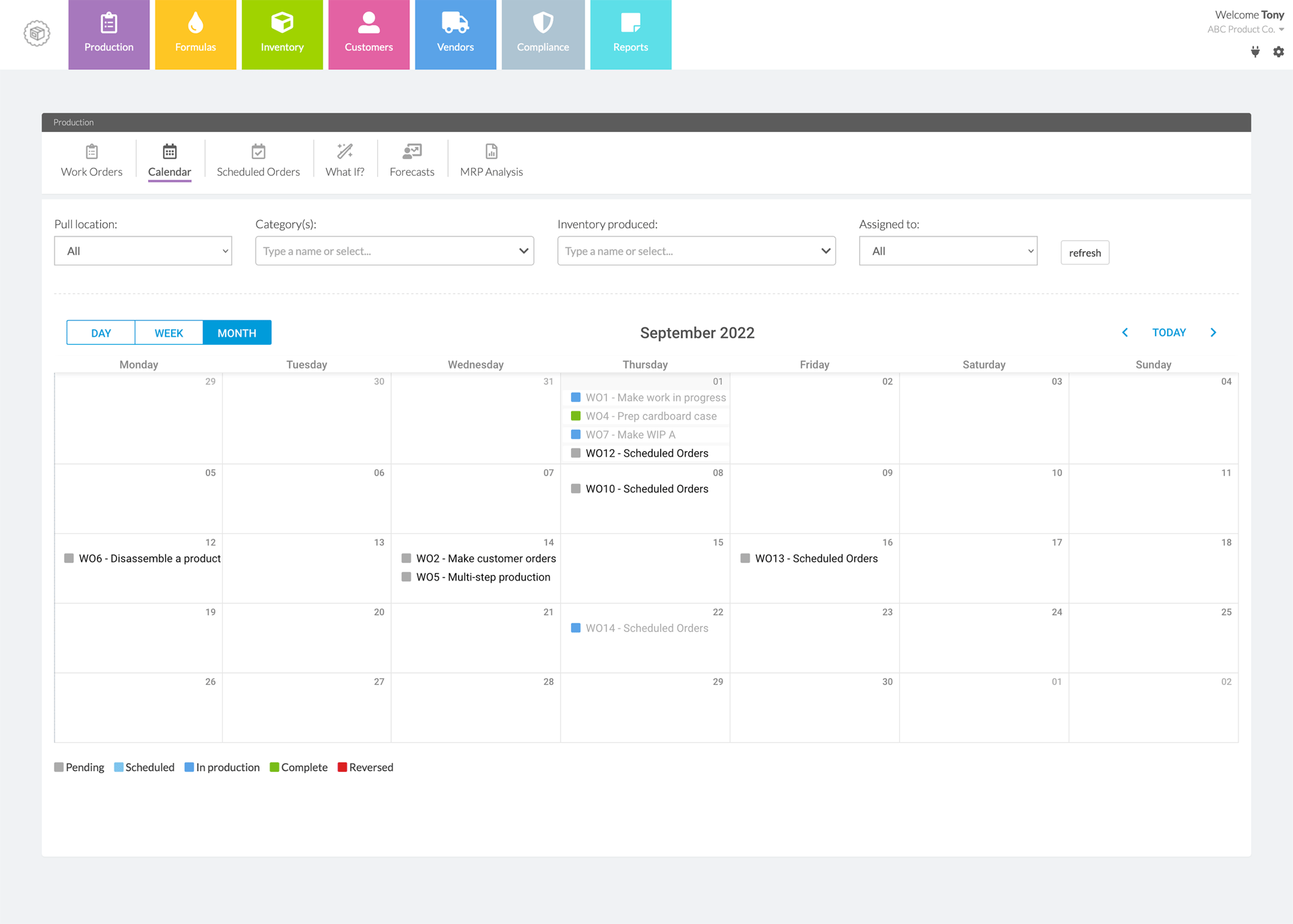

“Vision inspection systems make use of a range of 2D and 3D camera systems to monitor the performance of key processes—such as forming and baking—and to detect the presence of foreign contaminants. Increasingly high-resolution offerings allow detection of smaller foreign contaminants and defects, while new technologies operating in the non-visible spectrum are expanding the range of detectable contaminant types,” he adds.

“One such example is the MultiEye system from KPM Analytics, which uses a combination of Visible and Hyperspectral Imaging to detect a range of contaminants. Some examples of these contaminants include thin plastic films and sheets that otherwise may not be detectable using only metal detectors and x-ray systems,” Gilchrist says.

“Baking industry-focused suppliers of vision inspection systems are producing equipment that meets the high hygienic design standards of food manufacturers, and as an added benefit these systems are often fulfilling a key quality monitoring role that can lead to more efficient processes, waste reduction, and improved customer satisfaction.”

Eric Garr, regional sales manager, Fortress Technology, Toronto, says that, typically, snack manufacturers and bakery facilities will have more than one metal detector between the beginning and end of the production and packing process, corresponding to identified Critical Control Points (CCPs).

“The key is to identify the predominant risk points and install the most appropriate inspection equipment at specific checkpoints most relative to these risks,” he advises.

For loose and raw products, such as potato chips, cereal, corn, popcorn, and snacks, this will often be before the bagging stage, using a Gravity/Vertex metal detector, and then later down the line when bags are sealed, just before packing into boxes for distribution, Garr adds.

The reason for this is leaving it until the end of the production line could result in high levels of false rejects and unnecessary disposal of good product and packaging, he continues.