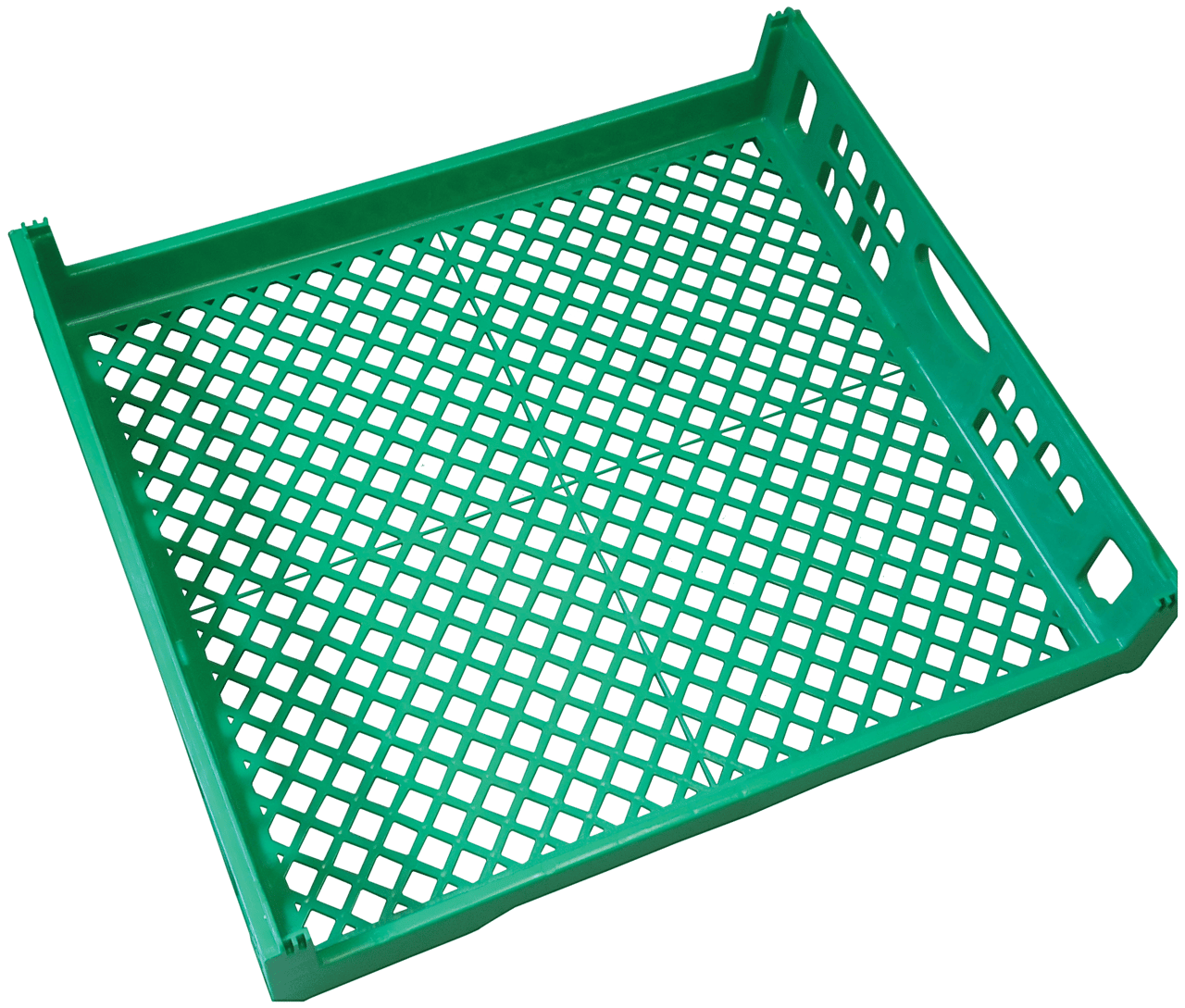

Bakery trays

packaging

The BOTTOM LINE

- RFID tracking and identification

- Improved safety and efficiency

- Sanitation challenges, including COVID-19

Bakery trays and similar items such as pallets and baskets are an essential part of the supply chain for bakery and snack producers in transporting finished goods for direct-store delivery. They are sometimes enabled with tracking and traceability technology such as radio-frequency identification (RFID) to prevent tray and pallet theft.

Safe, efficient transport

RFID tracking, hygienic features, and dimensional consistency improve performance.

Neal Lorenzi, Contributing Writer

Reusable plastic trays, which offer durability and ease of cleaning, are integral to the distribution of baked goods, according to American Bakers Association (ABA), Washington, D.C. Bakeries invest substantially in trays that are circulated between their plants, warehouses, and customers. The trays are collected after the baked goods are delivered to the customer, and the process begins again. The more a company utilizes a reusable plastic tray, the greater the return on investment and overall supply-chain savings.

Product improvements

Product improvements are increasing the benefits of bakery trays. The dimensional consistency of bakery trays and other reusable plastic packaging solutions allows them to integrate seamlessly with automated systems, an important consideration as bakeries continue to adopt more automated processes, according to Ken Rivard, national account manager at ORBIS Corp., Oconomowoc, WI.

“With this in mind, we are working with equipment suppliers to ensure that our solutions interface with their equipment,” says Rivard. “We’re also striving to make our trays more lightweight to help reduce shipping costs, conform to customers’ weight requirements, and improve the overall handling of these solutions.”

“We’re also striving to make our trays more lightweight to help reduce shipping costs, conform to customers’ weight requirements, and improve the overall handling of these solutions.”

— Ken Rivard, national account manager at ORBIS Corp.

Rivard adds that more bakeries are looking for full transport systems to efficiently move their product from production facility to retail. Combining trays and baskets with plastic pallets and dollies gives customers a full system to quickly move, store, ship and merchandise all types of bakery items. “Designing a full solution allows us to customize our packaging solutions to fit each customer’s unique needs, while providing the durability, sustainability, and accessibility they’ve come to expect from their packaging.”

Manufacturers today are producing more trays that incorporate recycled materials. They also are improving the lifespan of trays and baskets by including additives that allow for higher temperature sterilization without breaking down or wearing out over time, according to Ken Beckerman, product manager, Flexcon Corp., Berkeley Heights, NJ. “Closed-loop tray distribution and use cycles also help with reusability. Of course, plastic is cleaner than cardboard and wooden crates, lasts longer, and doesn’t rot and create dust or debris. Plastic is reusable, recyclable, and washable. Also, stackable open walls provide visibility.”

Among best practices used by bakery tray manufacturers and users, maintaining a hygienic supply chain is important. To that end, the smooth surface and drain holes of reusable plastic trays allow bakeries to easily sanitize and clean their packaging for reuse. “The smooth surfaces and contoured corners also prevent product damage and reduce the risk of dust and wood contaminants that may come with single-use or limited-use packaging. These solutions also use FDA-compliant materials, adding to their food safety benefits,” Rivard says.

Courtesy of SPF Plastic Group

To comply with best practices, keeping track of assets is essential in any closed-loop model. To that end, the ABA’s Fleet & Logistics Committee has developed a website, www.traytheft.org, to help bakeries in the fight against loss rates and illegal recycling.

“The content addresses the key elements in establishing awareness, education, technology, legislation and law enforcement initiatives,” says Glenn Rindfleisch, vice president of sales and marketing, SPF Plastic Group, Byron GA. “The goal is to promote a universal program for all industry associations to adopt. Track-and-trace models and the pursuit of state legislation to deter crime rank high on the priority list.”

RFID tracking

Indeed, RFID tracking systems can help bakeries prevent theft. In the high-speed world of food production, the tracking of trays and dollies is critical to optimizing the distribution network. “RFID can help bakeries find holes in the supply chain to reduce dwell time and prevent loss,” Rivard says. “For example, tracking can help illuminate a potential snag in the timing of the return trip. Knowing this can help improve the supply chain and packaging fleet operation.”

RFID tags store the information being tracked; these tags are easily scanned to track areas of bakery tray loss. The bakeries then perform corrective action to reduce or eliminate the loss. “Often this loss is not intentional and, with some guidance, easily eliminated. The majority of this loss comes from retail outlets and bakery product suppliers,” Beckerman notes.

Courtesy of Orbis Corp.

Technology such as RFID and bar coding acts as a license plate for individual assets. The more information available by using these tags, the better the bakery can track, trace, identify, and manage both product and asset in a closed-loop distribution model, according to Rindfleisch. “For example, collapsible reusable plastic containers (RPCs) used heavily in egg, produce and poultry categories utilize bar codes to sort, repair, wash, inventory and distribute RPC assets via a pooled model. This same technology is applicable to the bakery industry as automation and order selection continues to evolve.”

Among products recently introduced in this market segment, the new Odyssey pallet from ORBIS Corp. is hygienic, easy to clean, and offers anti-slip features to protect heavy product loads and streamline food production, the company reports. Commonly used for the cold and frozen storage of bakery products, the pallet’s smooth, plastic surfaces are free of nails and splinters to protect product and reduce warehouse debris.

Courtesy of Flexcon

Flexcon’s new 29x26x6-inch bread tray features generous heights up to 5.5 inches. It is designed for the efficient flow of bread and baked goods throughout the supply chain, from the bakery to grocery store to convenience store. When full, the trays stack securely for easy transport and merchandising. When empty, they cross-stack and nest for back room and truck space savings. “They can be combined with plastic pallets and dollies for a full system to quickly move, store, ship and merchandise all types of items from bakery to retail,” Beckerman says. “The plastic trays are fully recyclable at the end of their service life and asset tracking systems are available to reduce loss.”

Addressing challenges

Reusable transportation packaging such as plastic trays, collapsible RPCs, dollies, and pallets are constantly evolving to meet the needs of both the manufacturer and the consumer. Sustainability is a driving force in today’s circular economy.

However, external market conditions have created challenges. “Due to COVID-19 and large-scale economic pressure, industries that operate in a closed-loop distribution model are adapting to sourcing delays, labor issues, loss rates, higher raw material costs, freight increases, and rapidly developing E-commerce opportunities,” Rindfleisch says. He adds that these trends have hit the bakery industry particularly hard, given the short shelf life of baked goods. “Yet, we have seen bakeries implement impressive operational standardization and SKU prioritization to meet consumer demand.”

Specific to reusable plastic packaging, increased resin costs as a result of the catastrophic freeze along the Gulf Coast in early 2021 have added to the list of challenges. “Resin production and availability ground to a halt, resulting in a three-fold increase in material costs that persists today,” Rindfleisch adds. “For the bakery industry, where the use of plastic trays, dollies, and pallets is commonplace, the timing leading into the prime bakery season has forced bakeries to manage costs carefully. The availability of tray, dolly, and pallet floats are strained and will need replenishment when raw material prices recede.”

Looking ahead, Beckerman sees multiple potential innovations in bakery trays, including:

- Green materials such as plant-based plastics and packaging

- Additives to increase strength and durability

- Color-changing features for temperature- or humidity-sensitive goods

- More standardized sizes used across industries

- Features that allow for easier load securing and unitization on pallets or trucks without banding or wrapping