Ovens and proofers

Tech & Techniques

The BOTTOM LINE

- Energy efficiency is a high-priority item for oven and proofer buyers

- Ease of maintenance, including availability of parts, is another key concern

- Ongoing labor shortages make ease of use and automation appealing

Hot topics

With ovens and proofers, producers choose tech that tackles cost and labor concerns.

Ed Finkel, Contributing Writer

Energy efficiency, ease of cleaning and maintenance, and solutions to labor-related challenges are among the features and benefits most top of mind for snack food and wholesale bakery companies seeking new or improved ovens, proofers and related equipment.

Energy consciousness

Efficient energy benefits, specifically greener energy usage, are high on the list for customers of Reading Bakery Systems, especially larger companies looking to reduce their carbon footprint, says Sam Pallottini (director, cookie, cracker, and pet food sales), who notes that in cookie or cracker lines, the oven is the top generator of carbon emissions, particularly when using natural gas.

“A lot of people are trying to prepare themselves to do what they can to make changes in the future to electric [power],” he says. “You buy an oven now, it’s going to be around for 50 years. Who knows what power requirements are going to be 50 years from now, let alone 10 years, let alone five years. It gives you flexibility, with an electricity initiative to reduce your carbon footprint.”

These climate-related concerns first arose around the time of the Paris Agreement and haven’t instantaneously receded despite the changed political climate in the U.S., Pallottini notes. “The political landscape changes regularly,” he says. “Who knows what will happen in the next election? Having an oven design flexible enough to handle gas or electric is a nice step going forward.”

Courtesy of Reading Bakery Systems

Courtesy of Ashworth

Hybrid ovens with convection zones are the most efficient way to bake with reduced moisture and less energy, providing the option to convert that zone to electric as it makes sense, Pallottini says: “You can take steps going forward to focus the gas where it’s needed, initially, until you can change that out to electric.”

Reading Bakery Systems doesn’t do much with proofing other than pita chips or pretzels, which Pallottini says “are about product placement, so you can consider band-loading. Keep five layers or however many you have for proofing, so you can still maximize band-load into the oven.” Proofing focuses on holding a warm section with humidity and moisture—he’s been told an optimal cracker room should be 80 degrees with 80% humidity—to create the right flavor, he says. That’s also “the best way to maximize energy … [with] more BTUs per product.”

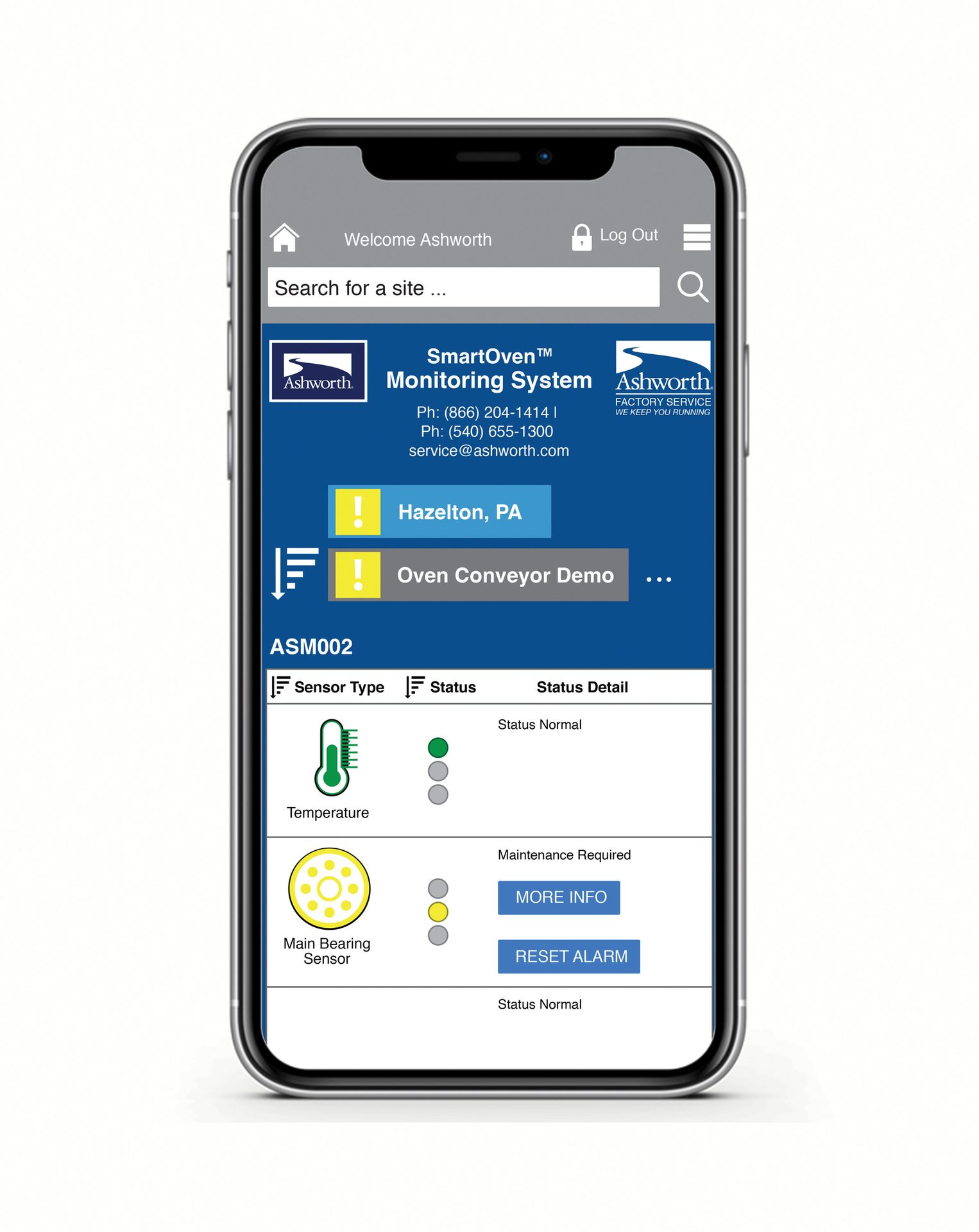

Customers of Ashworth are having growing problems with staffing and are relying on their in-house maintenance staff to be “firemen” who “fix things when they break,” creating roles that equipment companies sometimes fill, says Jonathan Lasecki, director of engineering,

“People are fixing things instead of maintaining things,” he states. “You can hire us to help do things the maintenance guys can’t do,” or don’t have the time to do, given turnover as well as manpower shortages. “Our service group can be contracted to do quarterly inspections, or whatever. We give them a report—here’s what needs to be done—or contract to come out the following week.”

Ashworth also offers training on maintenance and inspection, “so their people can be more effective,” Lasecki adds.

In addition to challenges in labor, the availability of parts for ovens and proofers can be a hurdle, Lasecki says. “You can’t order a motor and get it tomorrow,” he says. “In most cases, it takes four, five, six weeks to get certain parts in.”

Daniel Florencio, sales director, Americas for Revent, says his customers are very interested in automatic startup so that they can start equipment remotely, and be able to go directly and automatically from a cold storage to a hot environment, without anyone needing to control that on-site. “You can store in a cold environment at night, program [a product’s] curves throughout the evening, and it’ll be ready when you need to bake,” he notes.

Courtesy of Ashworth

This feature appeals to bakeries due to the higher costs of and challenges in finding labor, “especially for overnight shifts and challenging hours that are the norm for bakeries,” Florencio adds. “You can avoid some steps and then limit the amount of shifts you have.” In addition, Revent offers an ultraviolet light filtration system that enables bakeries to store dough for longer and “not have to worry about mold spores because of the controlled environment.”

In terms of product trends, Florencio points to the popularity of sourdough bread, helped to some degree by Taylor Swift’s enthusiasm for it, and also by its low glycemic index and people’s interest in being more gluten-conscious.

“Sourdough nails a lot of those checkboxes,” Florencio remarks. “It’s healthy and feels good for people. To make that type of bread, to reel that quality in, you have to let it proof for a long time. That’s what the retarder’s job is—you need to then get it ready from proof to bake, as it transitions from the cold to warm environment.”

Koenig also has noted the popularity of rustic, artisan-style breads, which has prompted more bakeries to turn to stone conveyor ovens to achieve the authentic crust and flavor on an industrial scale, says Julia Kneidinger, marketing manager.

“Today’s baking lines reflect a clear trend: product style drives oven design,” she says. “At the same time, production volumes are rising pushing the need for larger baking surfaces and faster throughput.” Koenig developed its MDI STRATOS tunnel oven for those reasons, she adds.

Kneidinger agrees with Pallottini that energy costs have become a decisive factor in product pricing, prompting bakers to pay close attention to energy use inside the oven—and prompting Koenig to focus on optimizing consumption through intelligent control and heat recovery systems, to ensure every unit of energy boosts productivity.

“As energy markets shift and new regulations emerge, flexibility is key,” she says. “Koenig’s oven designs are built for quick conversion to alternative energy sources such as hydrogen or electricity, helping bakers stay adaptable and sustainable in the years ahead.”

Courtesy of Reading Bakery Systems

On the proofer side, Koenig envisions a future that blends traditional craftsmanship with flexibility and intelligent, data-driven controls, Kneidinger says. “They’re data-driven ecosystems,” she says. “Smart sensors continuously monitor and adjust parameters like temperature, relative humidity, and air velocity to maintain perfectly stable conditions. Modern systems integrate seamlessly into digital production lines, allowing bakers to track fermentation curves and link proofing data with mixing and baking steps. This not only improves quality and repeatability but also creates valuable feedback loops for process optimization.”

Courtesy of Reading Bakery Systems

Courtesy of Reading Bakery Systems

Energy efficiency is important for proofers as sustainability goals ramp up across the industry, motivating companies like Koenig to engineer systems with features like advanced insulation and optimized airflow, to reduce consumption while maintaining the precise micro-climate required to maintain product quality, Kneidinger observes.

“Flexibility also applies to process control,” she says. “Proofing time, speed, swing number, and swing size can all be configured to accommodate different dough weights and product geometries within one system. This makes it possible to process a wide range of baked goods on the same production line without compromise.”

Key questions

When considering a purchase of new or improved ovens or proofers, customers should start by asking what support and service they can expect from a given company, and how quickly, Pallottini recommends. Other questions include how easily the machine allows for maintenance and sanitation, and how energy-efficient it is so that they can reduce their utility bills going forward.

“Efficiency, sanitation, maintenance, service, and support,” he sums up. “These decisions are driven, a lot of times, [by] a knee-jerk reaction based on lowest cost. But your real costs are what happen over the life of the product. Who’s going to be around to support that oven system? What parts can you get to help it run efficiently and effectively?”

Lasecki has certain questions he asks of customers when they’re considering a purchase, starting with what their long-term plan looks like.

Courtesy of Reading Bakery Systems

“They’ll say, ‘I need an oven that goes to this temperature, this wide,’ ” he says, meaning they are very present-tense focused. “We always ask, ‘What are you going to be producing five or 10 years down the road?’” They might answer, “I think I am going to increase production and maybe increase the width of products. Always look to the future, and purchase upfront maybe a little bit more than you need for today but can use later. We offer them check-sheets and things like that” to be able to think through such questions before they purchase.

Courtesy of Reading Bakery Systems

Courtesy of Delkor Systems

Delkor Systems plans to introduce a new generation of Combo-line Bread Case Packers designed as an all-in-one solution for single-use shippers and reusable trays in 2025. “Producers can switch between corrugated (one way) shippers and bread tray formats in the same machine,” says Dale Andersen, president and CEO. “Retailers are moving away from direct store distribution (DSD) trays and into corrugated cases due to the challenges and costs involved.”

Delkor Systems recently introduced Smart-Lock, which streamlines packaging size adjustments using a linear bearing slide, LED-based feedback and an automatic locking system. It reportedly eliminates the need for rotary counters, allowing precise, manual adjustments with minimal effort. “It is three times faster, more accurate and designed to virtually eliminate operator errors,” Andersen notes.

“Manufacturers are always looking at new products, formats, and SKUs, and inspection equipment needs to be flexible enough to support that.”

— Richard Reardon, general manager, Antares Vision Group