“Sanitation is absolutely critical in this industry, and there is a real shortage of well-qualified people in today’s market. The industry needs help, especially with the onslaught of mass hiring across the globe,” adds Robert. “Our food safety and sanitation course was created to fill a need in the market, and we used instructional experts who leveraged neuroscience principles for adult learning to help ensure that the training offers highly engaging content that can be reviewed at the participant’s own pace.”

He says that the food safety and sanitation course is an all-encompassing 24-module program designed to help mid-level managers and supervisors in the food supply chain more effectively handle their food safety systems. Due to its unique curriculum and design, participants can select from the 24 modules and complete those that are relevant to their needs or responsibilities.

“Modules were designed to meet the different needs of the food supply chain. For example, pest control companies can benefit from this training by selecting the eight modules that will provide their personnel with the knowledge needed to support an integrated pest management program in a food facility,” he comments. “Additionally, U.S. manufacturers and those exporting to the U.S. can use the content in these modules to gain a greater understanding of FDA regulations, industry best practices, and food safety principles, while those interested in other international markets can choose the non-FDA related modules to expand their knowledge of sanitation and food safety.”

Individuals in different roles within the food supply chain can benefit from the new training by selecting the modules that are most relevant to them. No limit is placed on the number of modules an individual can complete.

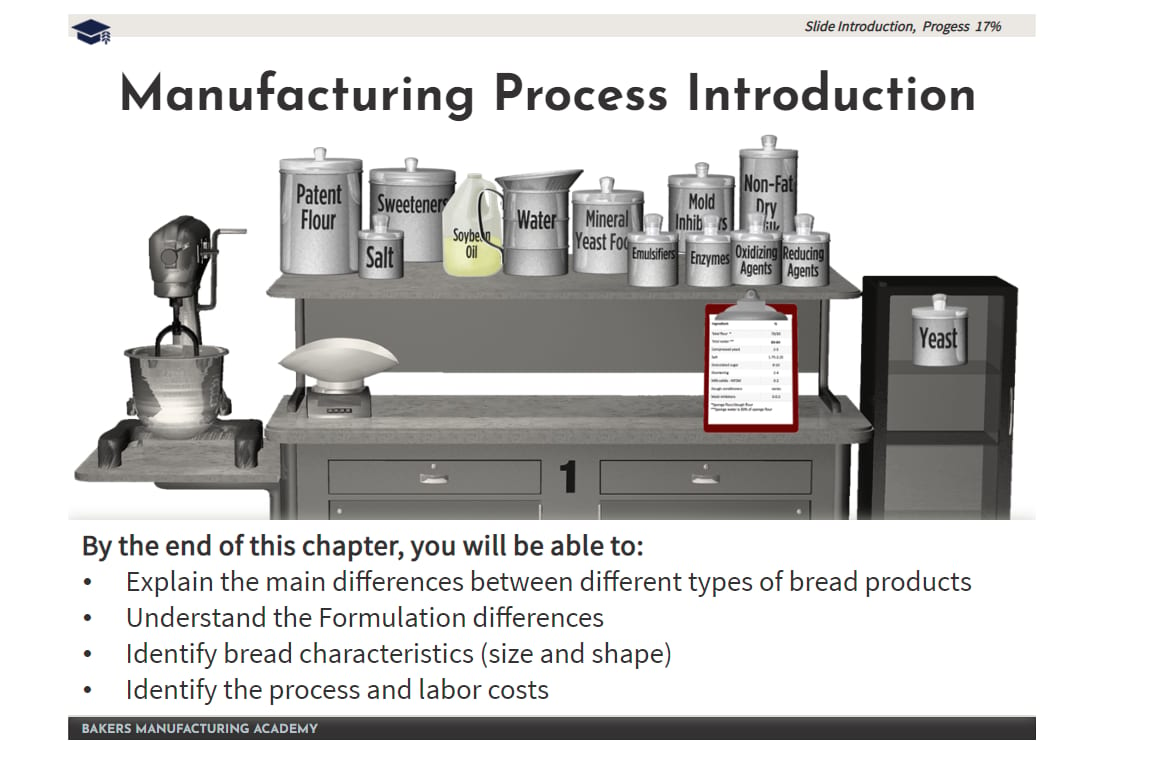

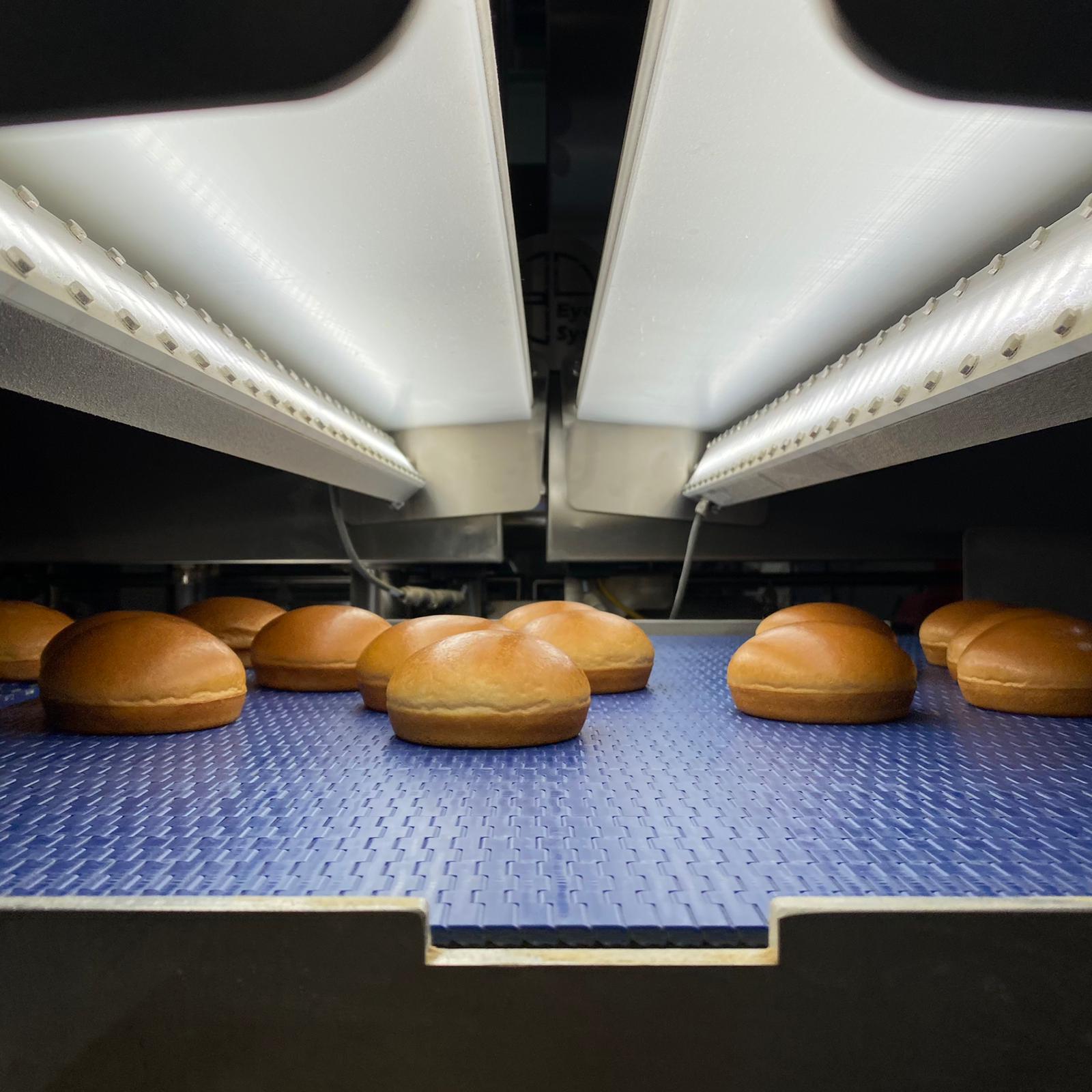

Vanessa Vial, assistant director of education, American Bakers Association (ABA), Washington, D.C., says that this year, ABA’s Bakers Manufacturing Academy launched an advanced training program for bakery’s most common product: white pan bread.

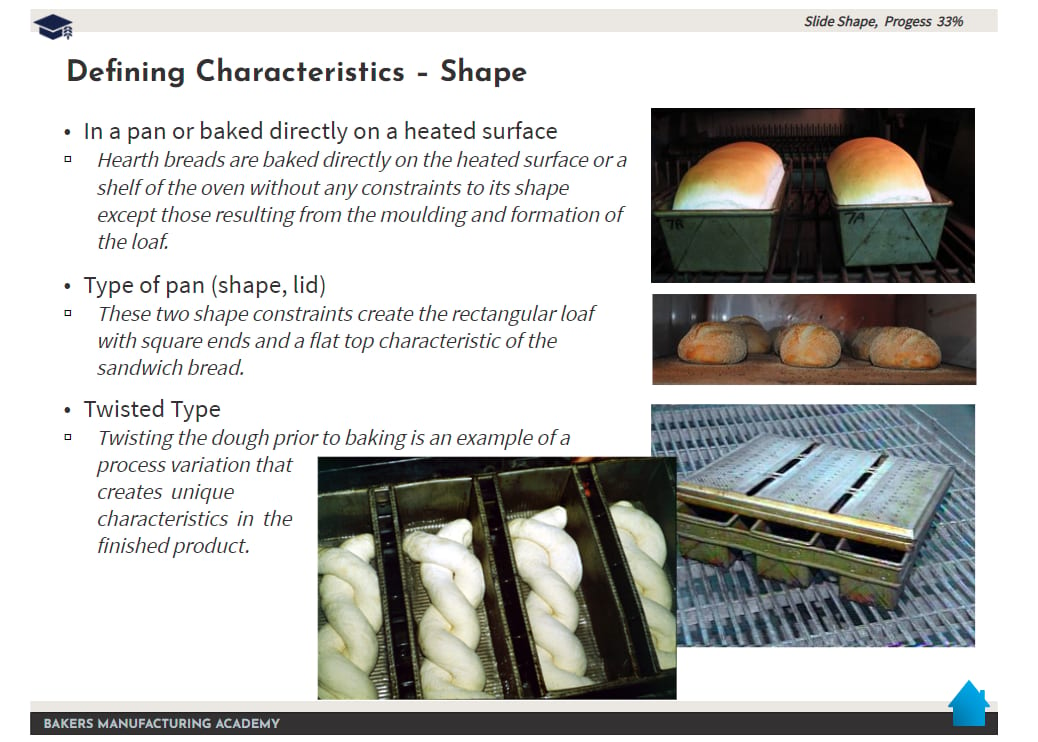

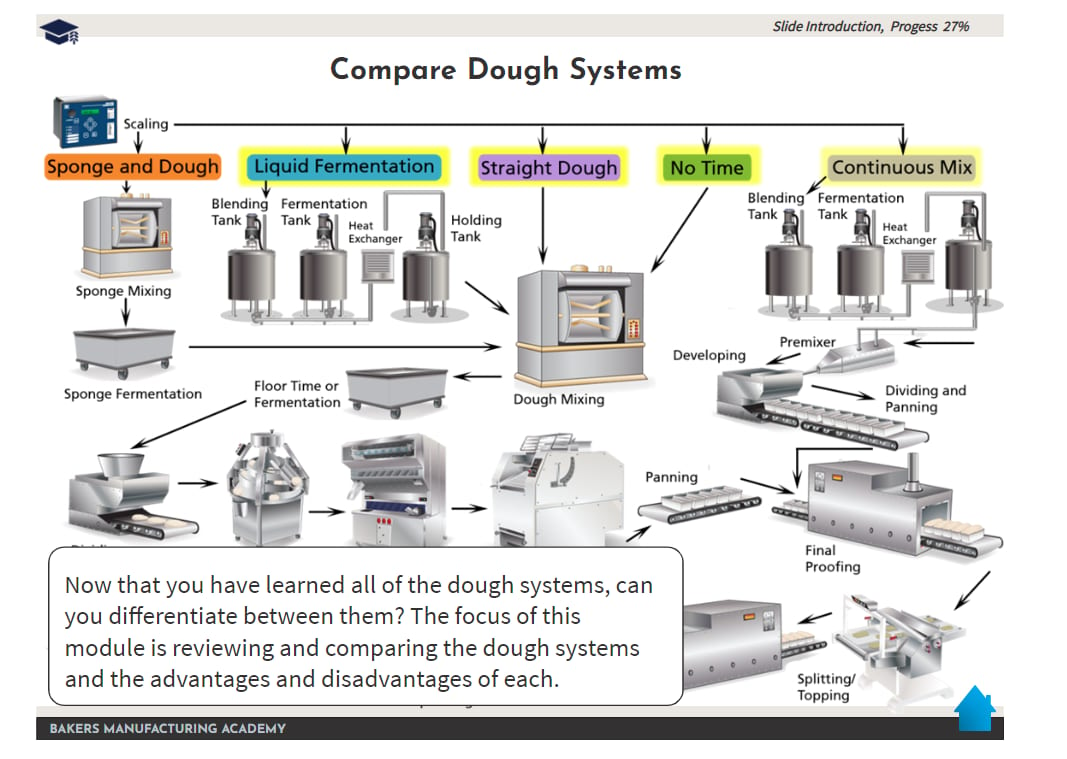

“The online course, available in both English and Spanish, is divided into two sections comprising 20 modules. The lessons focus on each step of the manufacturing process, from scaling through the packaging of the finished product. The ideal students for this course are those who want to manage or supervise and bakery shift, department, or facility,” she explains. “The flexibility of the Bakers Manufacturing Academy (BMA) allows entire corporations to integrate our training enterprise-wide by activating each bakery/facility location and enroll their workforce into programs that work best for their employee training goals.”

Robert says that with all the challenges the food supply chain is currently facing—for example, labor shortages and tight timelines—training should still be a top priority.