“Beyond sanitation and accuracies, snack and baking customers must, of course, be concerned about keeping packages and products free from foreign objects. Having the ability to integrate metal detectors with QA/QC equipment helps ensure the food products are safe to eat,” Peliska finishes.

Barry Voorhees (production manager, metal detection, Bunting, Newton, KS) agrees, saying foreign contamination is always a concern in food production—which is why critical control points (CCPs) are important.

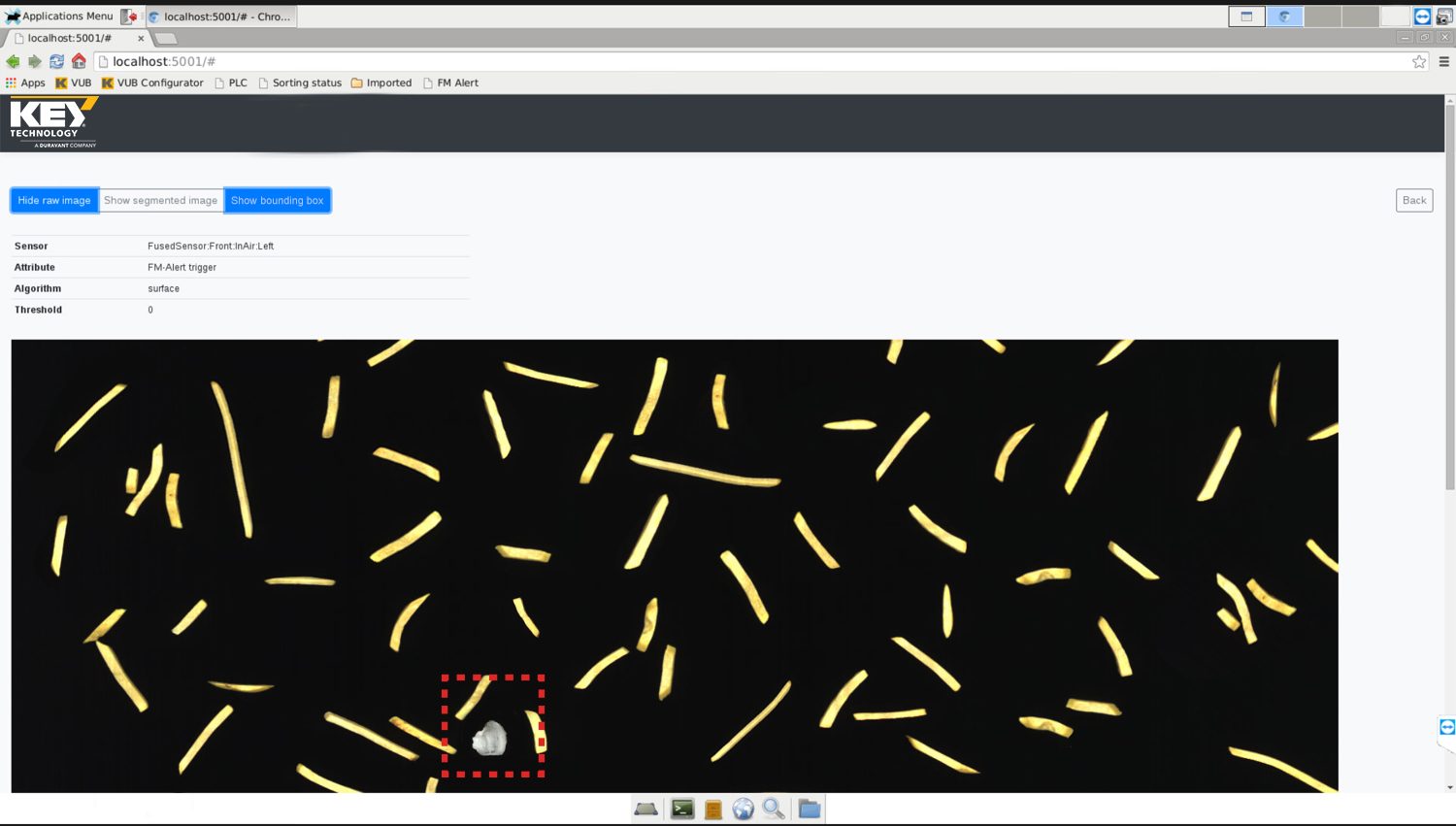

“Having the best sensitivity possible at those CCPs is vital to their operation for consumer and brand protection. The smaller the particle is that can be seen the better. What will vary by aperture size, product signature, etc., which are the typical variables in these applications. It is also critical that they check incoming ingredients and in process as well—not just relying on the end of line CCP locations to check for contamination. Having proper magnetic and metal detection systems in place throughout the process is always best practice,” he explains.

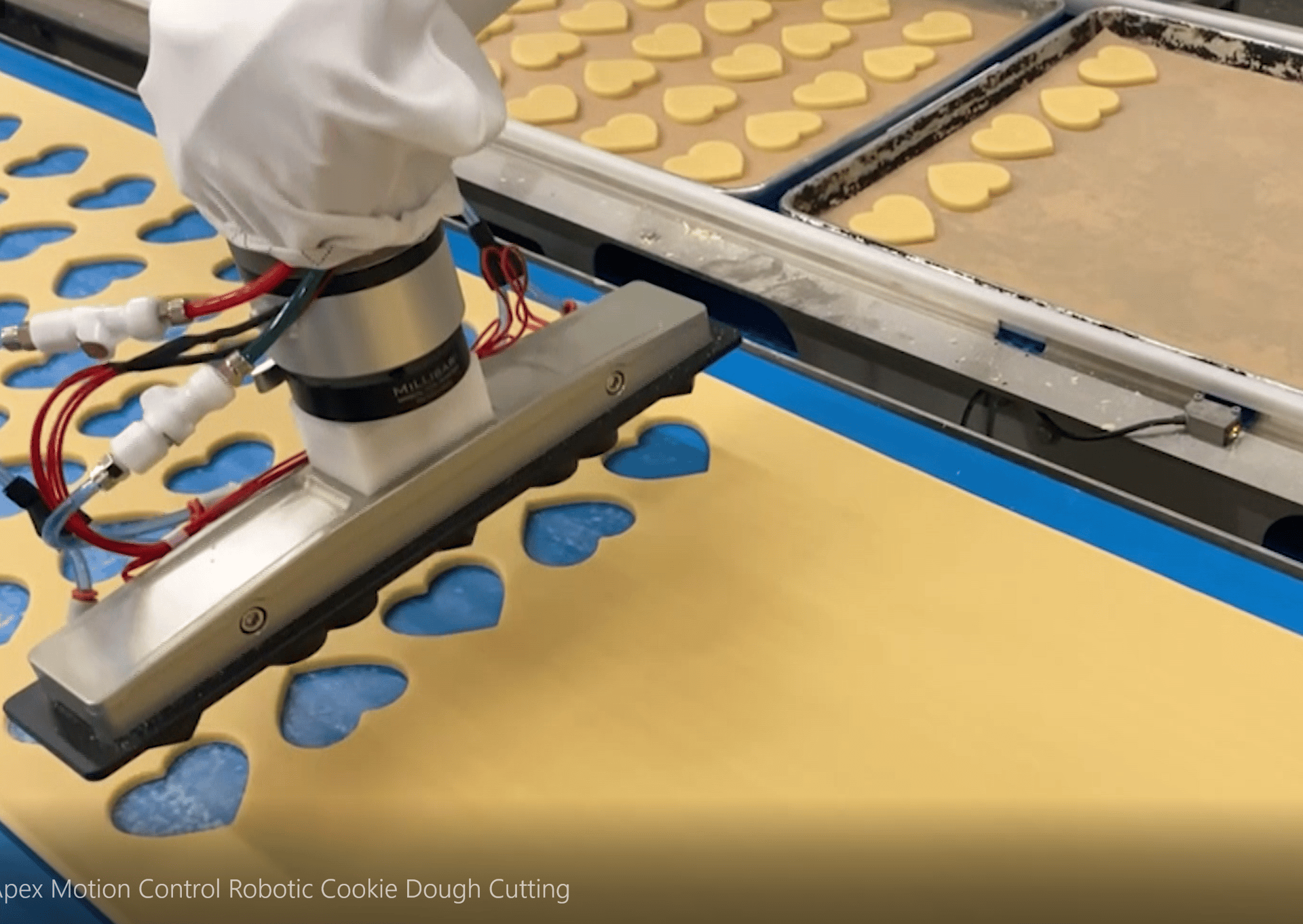

Eric Garr, regional sales manager, Fortress Technology Inc., Toronto, Ontario, says whether it’s gluten-free products, single-serve portions, large packs, or better-for-you products, snack and bakery manufacturers must evolve and meet consumer demands.

“Regardless of changing tastes, the primary concern for operators must always be food safety. The addition of new ingredients, flavors, own-label, sub-brands, pack sizes, and nutritional concepts means that a snack company’s average portfolio can easily comprise 100+ stock keeping units (SKUs),” he notes.

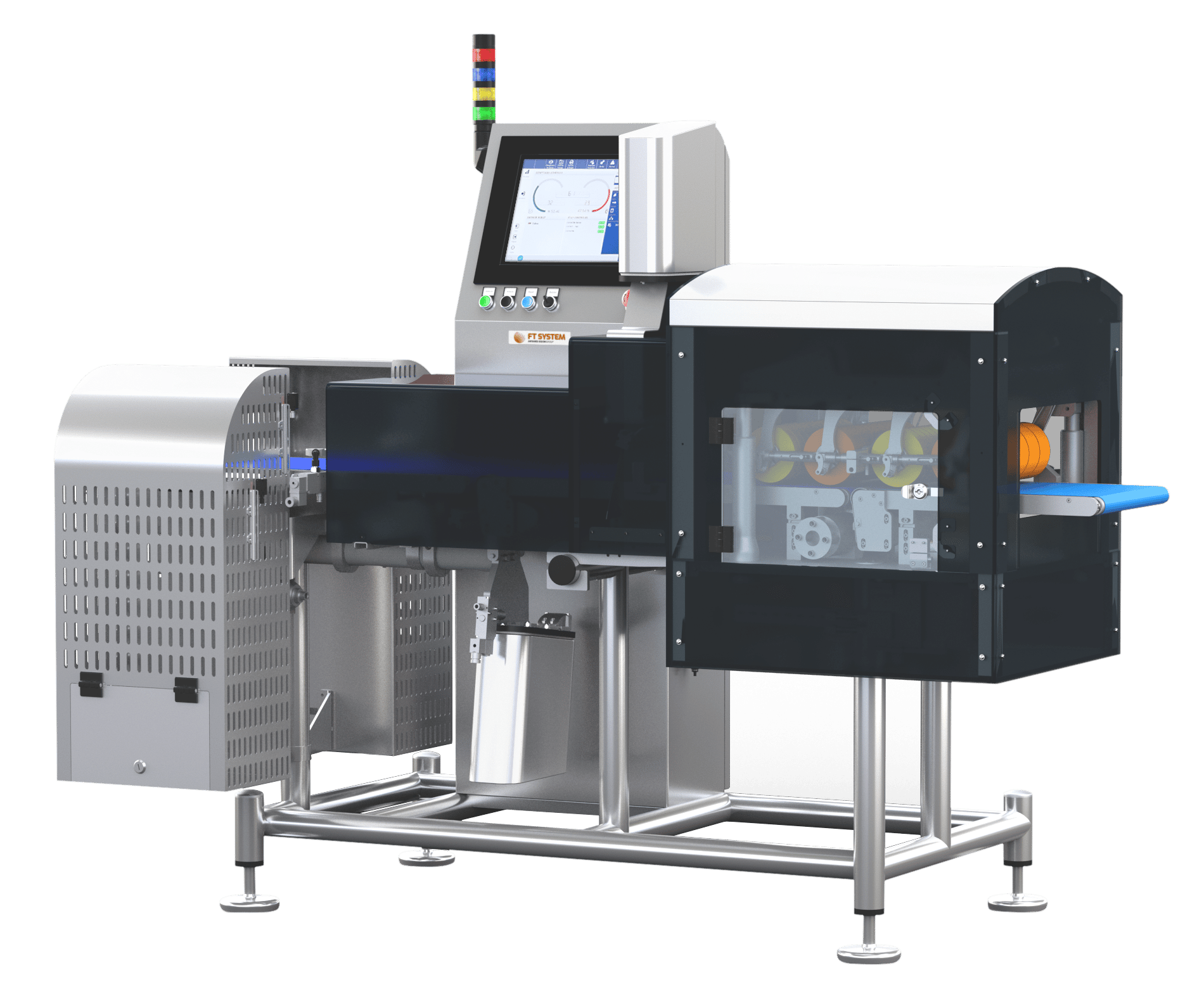

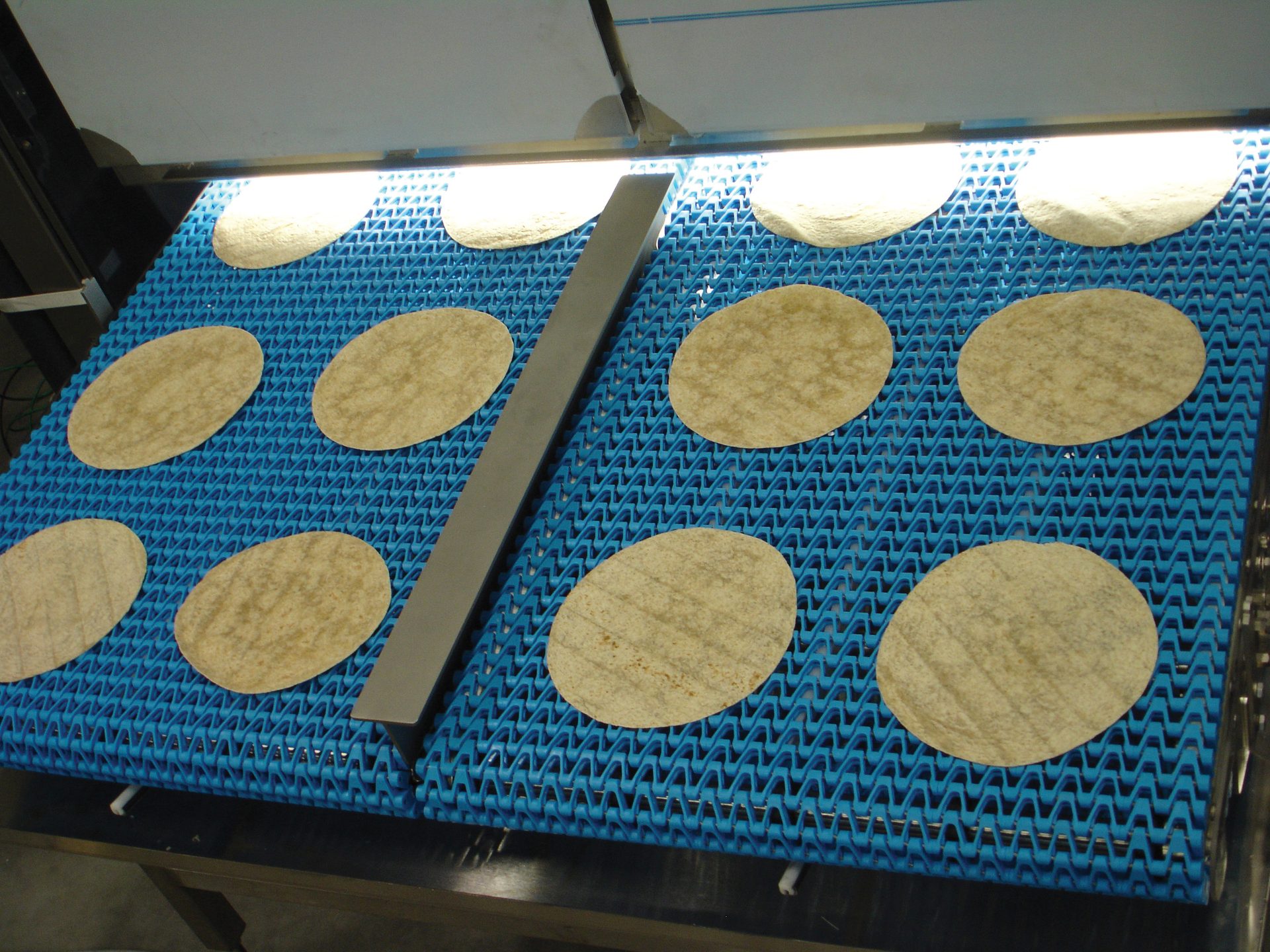

“Metal detectors, checkweighers, and X-ray inspection systems are essential to the production process; however, producers need to ensure their inspection solution is sophisticated enough to inspect different kinds of food products, but also different types of packaging,” Garr recommends.

The ability to efficiently inspect high-value ingredients of varying size, characteristics, and densities within products is always a high priority for purchasing inspection equipment, he says.

“Quality managers on these processing lines need inspection machinery to perform reliably with minimal downtime, yet also reject contaminated products accurately, without incurring high levels of false rejects. For loose and raw products, such as potato chips, cereal, corn, popcorn, and snacks, inspection CCPs will often take place before the bagging stage using a metal detector, and then later down the line when bags are sealed, just before packing into boxes for distribution,” Garr adds. “The reason for this is leaving it until the end of the production line could result in high levels of false rejects and unnecessary disposal of good product and packaging. In addition, packaging for snack foods is typically metalized film, which can limit the performance of a metal detector.”