The snacking business has boomed during the pandemic with people working from home, which has meant the need to be able to handle a greater variety, says Neil Anderson, vice president of business development for PPM Technologies, Newberg, OR. As manufacturers of snacks start to implement those additional varieties, the cheapest way is to maintain the base product and keep coming out with new flavors, he says.

Snack makers also have been more aggressive about crossing into one another’s turf during the pandemic, Anderson says. “Companies that traditionally have done a chip type of product, corn chip or potato chip, now are starting to do popcorn,” he says. “Guys doing popcorn are thinking about an extruded product like cheese puffs or cheese curls. We’re seeing new lines coming in from traditional and nontraditional sources.”

Healthier snacks have been part of the mix, although Anderson doesn’t think they’ve diluted the market share of more standard snacks very much, and he says the former formulations don’t impact the equipment that profoundly. “It often requires a much smaller amount of either liquid or seasoning. That can be a challenge,” he says. “It takes some reengineering of systems to provide that, which we’re pleased to do.”

PPM has been working more with snack makers in Latin America, who Anderson notes tend to have “different standards for flavorings than in the U.S. We’ve had to modify the design of our equipment to accommodate that. The put on a very high percentage of spicy types of flavorings.” Their demands have increased, as well, he notes.

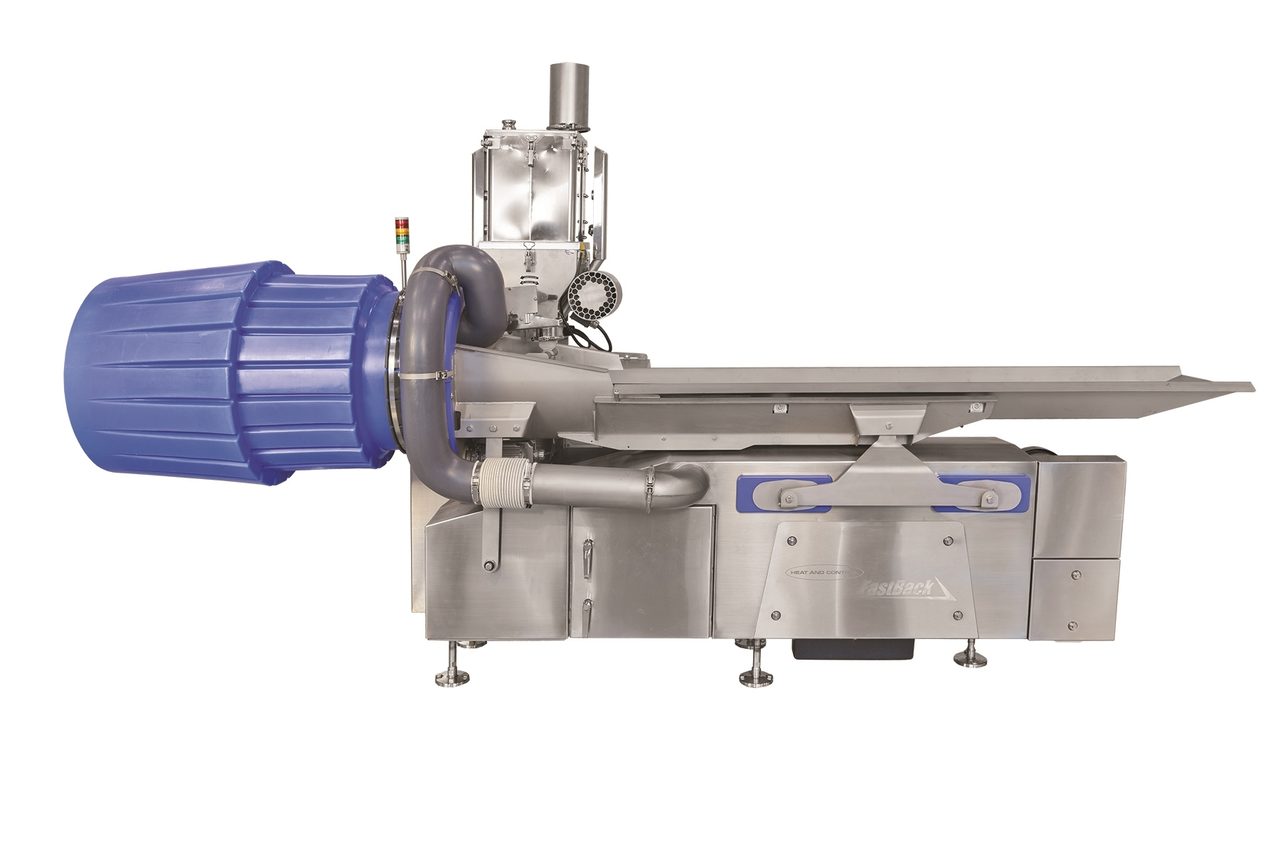

PPM has upgraded its FlavorWright system to offer the FlavorWright All-in-One, a module that incorporates an infeed conveyor, seasoning drum, seasoning applicator, and an oil spray system that work off of integrated controls via a touch-screen display, Anderson says. “It’s a plug-and-play system,” he says, adding that it can be used for all types of snacks, with variations available in the length of the drum and the size of pumps and nozzles used for liquids.

With the greater variety of types of snacks and flavorings, PPM has seen manufacturers who once might have run 5,000 pounds per hour of potato chips through one enormous drum, and then apply nothing but salt for three days, now buying an individual seasoning system for each scale, Anderson says. “And however many scales they have, they have that many flavors,” he says. “We put in an integrated system that would allow you to apply seasoning onto a certain amount of chips as they got fed onto the scale.”

“We work with a lot of the snack companies to integrate their seasoning combinations,” he says. Some might be stickier, some might be more flavor-sensitive, he adds. “We’re able to work with them to apply higher or lower rates, and in some cases modify the equipment, so that it reduces the buildup of seasoning and reduces the waste.”