The BOTTOM LINE

Premiumization strategies

Seasonal and LTO snacks

Mindful indulgence

Mindful indulgences

Consumers continue to indulge in bakery snacks, but some need permission first.

Liz Parker, Managing Editor

Bakery snacks and snack cakes will always be popular, both for their portability as an on-the-go treat and for feeling like a “small indulgence.” Even during the COVID-19 pandemic, consumers are still gobbling up these tasty treats, and if they’re pre-portioned, that’s a plus too.

bakery snacks

STATE of the INDUSTRY

Market data

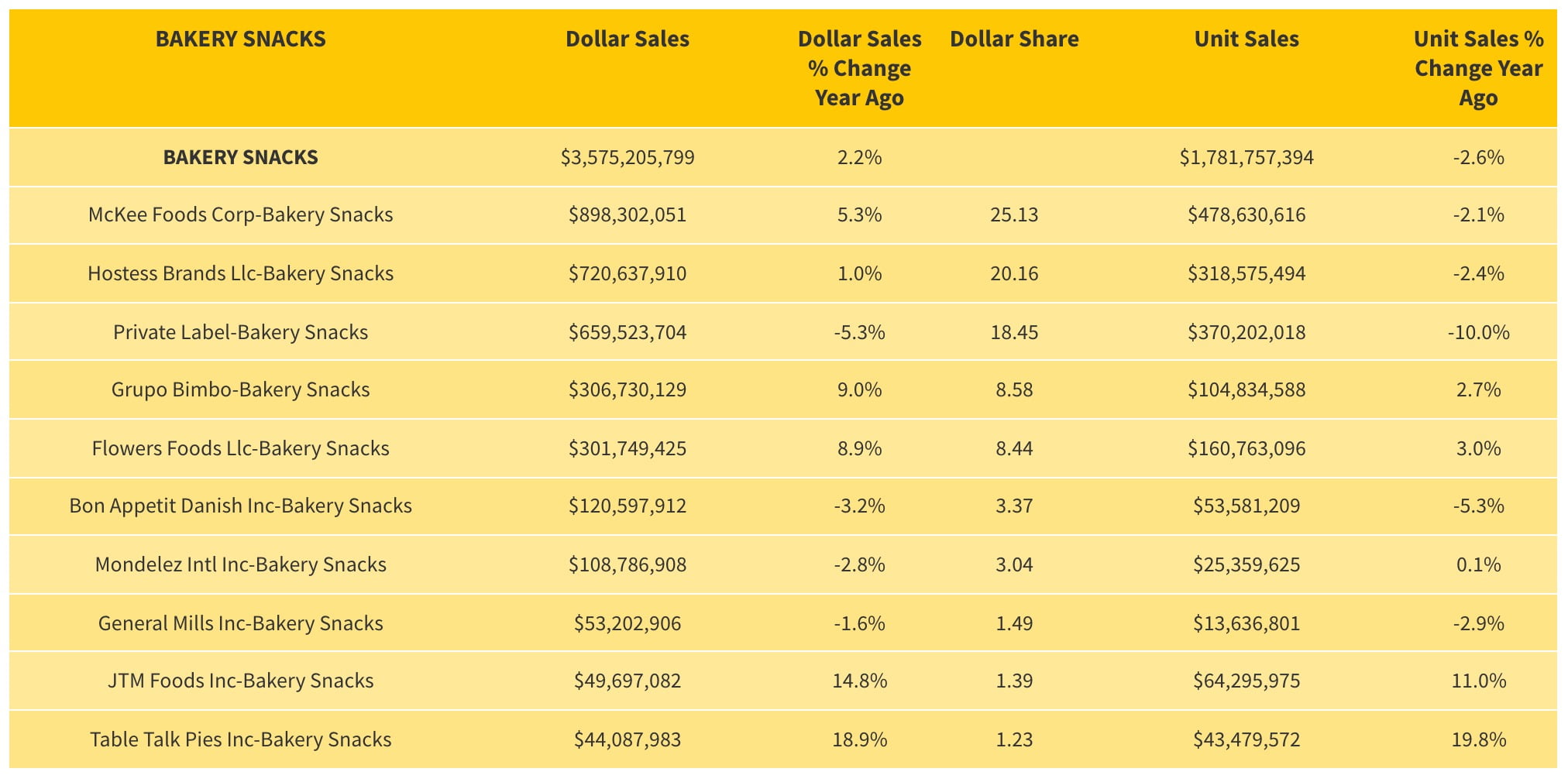

According to data from IRI, Chicago from the past 52 weeks ending April 18, 2021, the bakery snacks category, consisting of snack cakes and snack pies, was up 2.2 percent, with total sales of $3.6 billion.

McKee Foods, owner of the Drake’s and Little Debbie brands, was again the leader in the category, bringing in $898.3 million in sales with a small uptick of 5.3 percent versus the previous year. Hostess Brands brought in $720.6 million in sales, with a 1.0 percent increase. Other notable gains include Grupo Bimbo, up 9.0 percent to $306.7 million, and Flowers Foods, up 8.9 percent to $301.7.

Source: IRI, Chicago, Total U.S. Multi-Outlet w/ C-Store (Supermarkets, Drugstores, Mass Market Retailers, Gas/C-Stores, Military Commissaries and Select Club & Dollar Retail Chains), Latest 52 Weeks Ending April 18, 2021.

PINCH TO ZOOM IN ON CHART

Source: IRI, Chicago, Total U.S. Multi-Outlet w/ C-Store (Supermarkets, Drugstores, Mass Market Retailers, Gas/C-Stores, Military Commissaries and Select Club & Dollar Retail Chains), Latest 52 Weeks Ending April 18, 2021.

HOVER OVER CHART TO SCROLL DOWN

“Creamier—and more-abundant—fillings, and rich flavor cues like ‘triple chocolate,’ are all part of today’s snack cake landscape.”

— Jamie Mavec, marketing manager, Cargill

Snack pies also trended forward for the year. JTM Foods Inc. increased sales by 14.8 percent to $49.7 million, and Table Talk Pies increased its sales by 18.9 percent to $44.1 million.

Looking back

“Premiumization and indulgence are two of the big trends in the snack cake space, which means brands must deliver on consumers’ high expectations for taste and texture,” says Jamie Mavec, marketing manager, Cargill, Minneapolis. “Creamier—and more-abundant—fillings, and rich flavor cues like ‘triple chocolate,’ are all part of today’s snack cake landscape.”

Seasonal and limited time offers remain popular, giving brands an opportunity to add excitement and tempt customers with something new, says Mavec.

Pumpkin spice is always popular in autumn, and this year, Hostess released limited time offerings such as Pumpkin Spice Twinkies and Hostess Iced Pumpkin Cupcakes. Similarly, Tastykake usually releases seasonally timed bakery snacks, including its Valentine’s Day offerings in January 2020.

“After a year of pandemic limitations, there’s plenty of pent-up demand for novelty. Whether it’s spring-time lemon flavors or pumpkin-spice for a fall infusion, these limited-run products can strike the perfect balance between consumer desires for new and different, with their need for the comfort of the familiar. Perhaps that’s why we’re seeing these tasty treats push into new dayparts, as some brands position new entrants as a mid-morning pick-me-up,” Mavec says.

Still, there’s a segment of the market looking for “permission” to indulge, Mavec notes. “For these consumers, snack cakes’ prepackaged, portion-controlled nature can help rationalize the splurge or mitigate the guilt. In that same spirit, broader industry trends suggest brands that embrace label-friendly formulation will find a loyal following.”

Courtesy of Puratos USA

Jessica Blondeel, senior product manager, patisserie, Puratos USA, Pennsauken, NJ, points to company research showing consumers are still looking to indulge, but they want to do so in a more-mindful way. “Our Taste Tomorrow research confirms that 87 percent of consumers read the product label, with special attention to front-of-pack claims and the ingredient deck. What is really interesting is that consumers no longer solely define the healthiness of a product by what is removed (e.g., less sugar, fat, or unfamiliar ingredients) but are increasingly looking for ingredients that they consider both tasty and healthy (e.g., more fruit, nuts, and grains).”

A second major trend is everything linked to sustainability, adds Blondeel. “Consumers want to feel good about the products they purchase, resulting in a big uptick in locally sourced fruit fillings, products that guarantee a fair price for cocoa farmers and plant-based baked goods. The trend toward plant-based alternatives is especially relevant in the bakery world, where eggs, dairy, and butter play a critical role in taste and texture,” she says.

Puratos research found 62 percent of consumers have recently purchased and consumed plant-based chocolate and bakery product alternatives, a trial rate that’s significantly higher than that of other plant-based food, Blondeel comments. “Even though affordability has become top of mind for a lot of consumers, we see a trend towards more premium and super-premium items. Consumers want to treat themselves and will are choosing quality over quantity.”

On the ingredients side, proper handling of the oil used in processes such as frying is critical to ensuring the finished product quality and also prolonging the usage life of the oil, says Rick Cummisford, director of quality control, Columbus Vegetable Oils, Des Plaines, IL. “Companies need to consider frequent filtration and even treatment of the oils to remove particulate and even absorb some of the undesirable materials formed as the oil degrades, such as free fatty acids and polar materials. If successfully done, the oil can be used for longer periods of time before needing to be changed,” he suggests.

Cummisford says that routine cleaning of the processing equipment is also important, but make sure that the equipment is thoroughly rinsed and dried prior to adding oil. “The condition of the used oil should also be monitored for Free Fatty acids and polar material, both of these can pose issues to the finished product quality.”

Courtesy of Columbus Vegetable Oils

David Bezenyei, sales manager, Columbus Vegetable Oils, says that food manufacturers creating natural snacking formulation for baked and fried snacks gravitate toward high-oleic oils for that offer properties like a higher heat tolerance, ability to extend fry life, and lengthy shelf life.

“Our oils here at Columbus Vegetable Oils can help manufacturers achieve a more attractive label by way of using healthy oils in their products. Oils like canola, safflower, and sunflower—high-oleic oils—or oils that are GMO-free or organic, help meet the demand for clean and transparent labels that consumers care about. Using these types of healthier oils not only boosts awareness around a product’s health halo, but also helps to diversify flavor qualities.”

Looking forward

“We have had some customers interested in exploring formulas for special diets, primarily around vegan, keto-friendly and gluten-free. In vegan formulas, the challenge is egg removal, which typically requires a mix of starches, other hydrocolloids and plant protein to replicate functionality,” says Allison Leibovich, technical innovation advisor, Cargill.

“For keto-friendly formulations, the key is reducing carbohydrates, including sugars. For these applications, we rely on stevia, erythritol, and chicory root fiber. Stevia replaces sugar’s sweet taste, while chicory root fiber and erythritol serve as bulking agents, enhancing body and mouthfeel in reduced-sugar baked goods. In addition, we may use ingredients like xanthan gum to help bind water, build viscosity and enhance texture,” says Leibovich.

Gretchen Hadden, marketing communications manager, Cargill Cocoa & Chocolate, Minneapolis, says that Cargill has a broad portfolio of ingredients, including many that find their way into snack cakes. “For example, our Gerkens Duchess cocoa powder is designed specifically for baked goods, with an appealing chocolaty smell and taste confirmed by consumers, and an appetizing red-brown color. Going one step further, our Wilbur Duet product functions like cocoa powder, but also includes chocolate liquor, enabling a real chocolate claim. This is a perfect option for customers looking to up the chocolate experience and deliver on consumer desires for premium, indulgent treats,” she recommends.

Mavec says that Cargill’s products also address manufacturers’ needs. “For example, our PalmAgility shortening line helps fill a gap in our bakery customers’ portfolios by providing a single solution to a range of common challenges—including transportation, storage, and performance,” she notes.

Courtesy of Cargill

Most fats are sensitive to temperature swings, so customers need temperature-controlled storage to ensure their shortenings don’t get brittle or too soft, says Mavec. “Shortenings exposed to extreme heat or cool temperatures can impact processing and product quality. Many of our customers have limited space for staging fats to get them ready for processing and so they turned to us for a solution. In response, our research and development teams heavily invested time and resources to design PalmAgilty, a palm-based shortening that is more temperature tolerant, with greater plasticity for a broader working range,” she says. “PalmAgility stores easily, tolerating temperature swings without sacrificing workability or texture. This also helps address issues that can develop in transport due to fluctuations in outdoor temperatures, a variable outside of the customer’s control. In addition, PalmAgility shortenings provides a smoother, creamier texture than standard palm oil shortenings. This aids in faster mixing time and better incorporation of all ingredients, both of which are easier on baking equipment.”

Blondeel says Indulgence is all about taste, but 63 percent of consumers also like to try food with new textures. “Texture has become an integral part of taste, which is why we believe that texture is the new taste. We have unique ingredients to help bakers rethink the role texture can play in sweet goods.” She notes the cake texture collection from Puratos includes unique textures from around the world: from pound cake to chiffon and castella (a Japanese sponge cake).

A second opportunity lies in connecting with consumers on a more-emotional level, Blondeel suggests. “Consumers want to feel good about the items they indulge in, they want to contribute to a better future. Therefore, in my opinion, sustainability and plant-based are primed for growth. 81 percent of consumers are willing to pay more for sustainable products, and plant-based shoppers spend 61 percent more on groceries. A big driver behind plant-based alternatives is that they do not only appeal to vegans, but a much-broader audience of flexitarians. In fact, plant-based is the new vegan, with 36 percent of U.S. consumers embracing a flexitarian diet, and 37 percent considering plant-based options when they dine out. To help create a better future for all, we are strengthening our commitment to Plant Forward and Cacao-Trace,” she says.

Courtesy of Puratos USA