Big data

How do data analytics, artificial intelligence, and lean manufacturing factor into this equation?

“The more data you have at your fingertips, the better it helps to inform decision-making and add human-like elements to robotics and automation,” says Green. “Artificial intelligence can take the data that is fed to it and add more efficiency and capabilities. This helps manufacturers produce better products and meet consumer demands.”

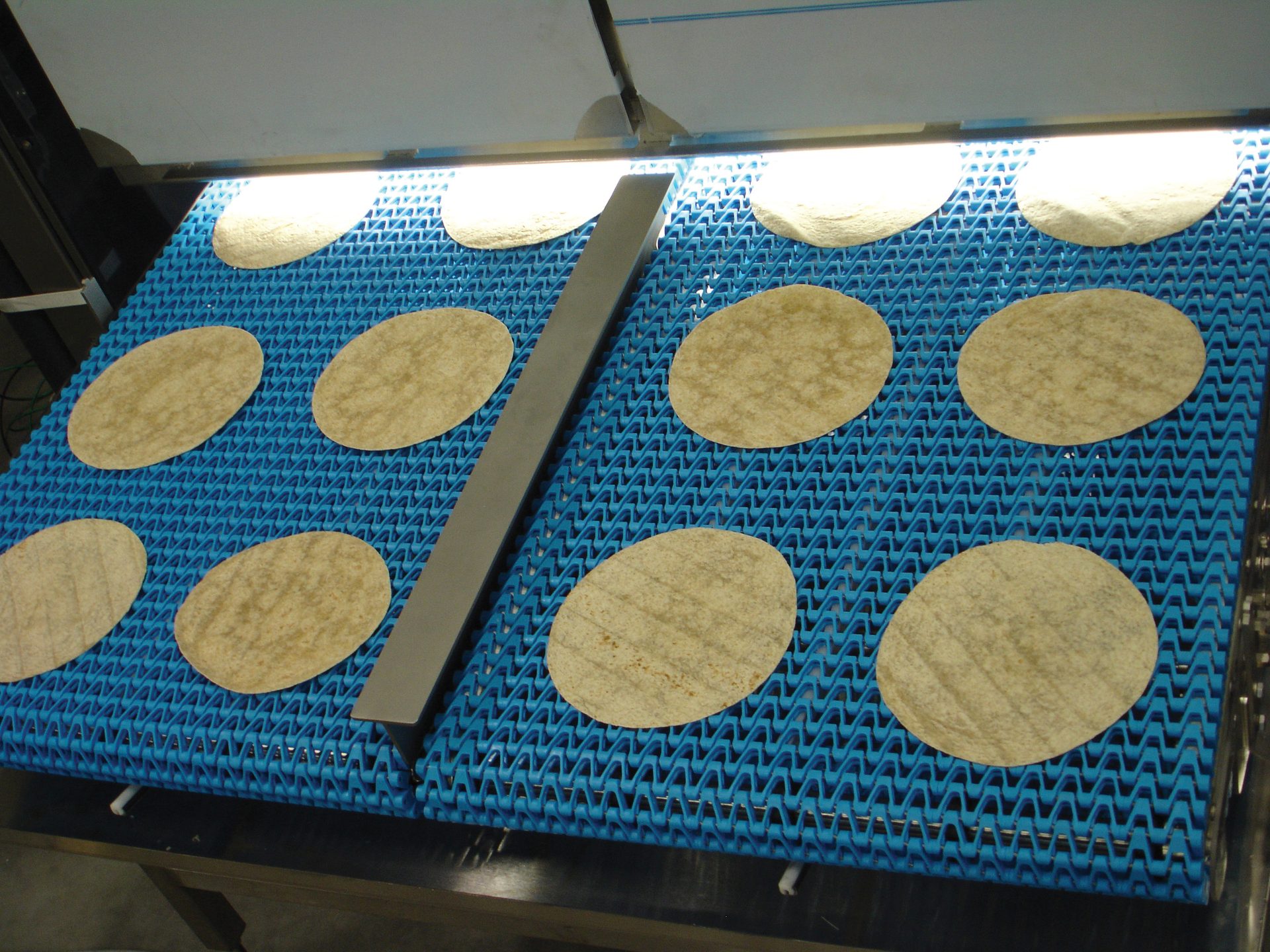

Automation, especially robotics and vision, often brings some level of analytic capability with it, according to Craig Souser, president and CEO, JLS Automation, York, PA. “For example, we use vision sensing on all of our systems, which allows us to report on the number and type of rejects. Artificial intelligence allows automatic changes to be made to a process based on machine learning algorithms, which adjust process parameters based on ongoing examination of the results. With respect to lean, automation will often force the issue when it is properly implemented, eliminating wasted handling of products and packages.”

Jerry Buckley, south central sales manager, BluePrint Automation, Chesterfield, VA, says that robotic vision systems can accurately review product size, shape, imperfections, and color. They can accurately reject out-of-spec items by not picking and placing them into their targeted destination (such as a wrapper infeed chain, tray/carton, or shipping case). It is difficult to accomplish this at high speeds without robotic vision systems.

Artificial intelligence and machine learning software packages are finding more applications. One interesting application for artificial intelligence for bakery and snack producers over the next few years is quality inspection, according to Caldwell. “In the food industry, where labor shortages are becoming more serious while stable quality is required, automating the quality inspection process is one path that can ensure that food is safe to consume.

“Since many food goods are produced in different formats, inspection has traditionally been done manually, making it difficult to quantify the criteria for good or bad products,” Caldwell continues. “Via deep-learning artificial intelligence, robotic inspection systems can determine no-good patterns for food products with the same level of accuracy as humans.”