Egan Food Technologies, Grand Rapids, MI, hears from customers who want to form healthier products with fragile ingredients like nuts and seeds without them getting crushed, says John Micelli, who handles sales and business development. He’s also seen more sourcing from organic farms, infusions of hemp into snack products, and molded chocolates. “Natural is the big thing,” he says.

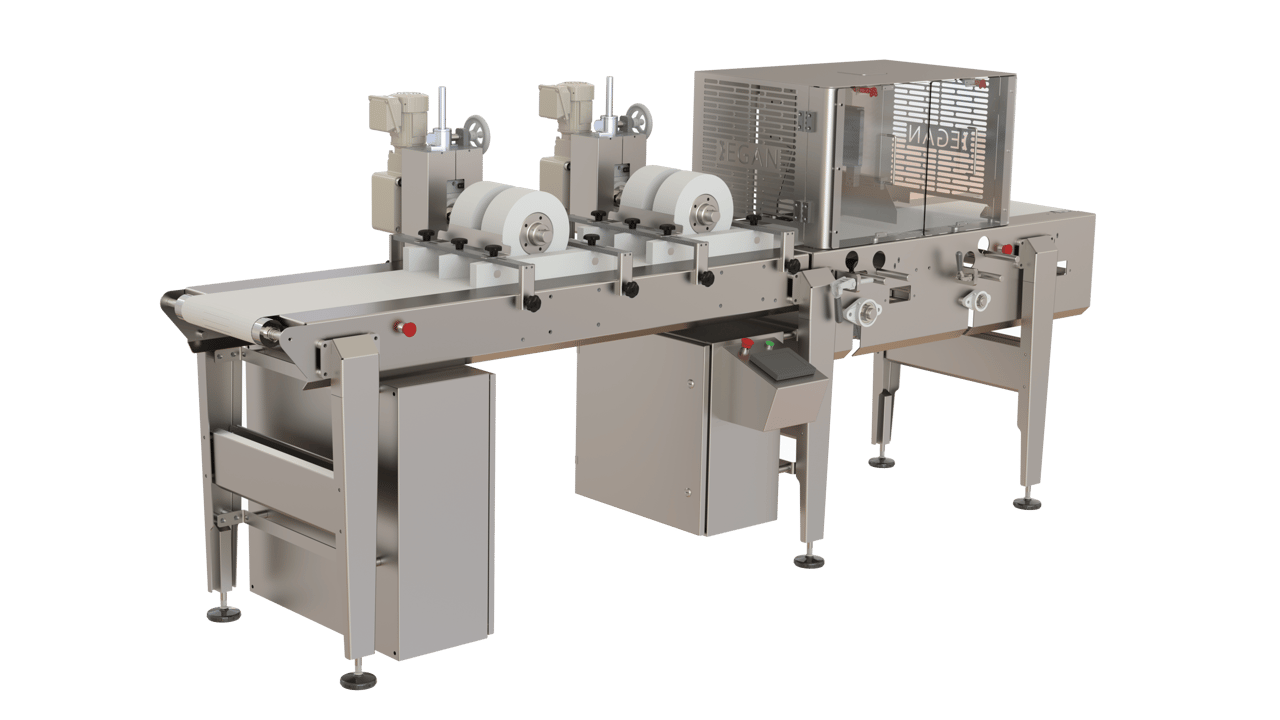

Egan last September unveiled the SlabForm DUO line, which produces granola, nutrition, and protein bars in more efficient fashion for smaller shops, Micelli says. Typically, such bars are formed in a large slab on a moving conveyor belt that might measure 1½ x 2 feet wide, which then has to be slit into, say, 10 “lanes” that then go into the guillotine to be cut to the right length. They also need to be chilled in a cooling tunnel prior to slitting so they’re very firm.

“It’s quite an elaborate process, where a typical line could be 70 feet long or more,” he says. “It’s a rather expensive capital investment. Smaller manufacturers, the artisans, the up-and-coming segment in granola, they typically either can’t afford the capital investment because their volume isn’t high enough, or don’t have the space to put large lines in.”

The DUO aims to solve that dilemma by forming a “mini-slab” that’s only as wide as the bar length, more like 4 inches, Micelli says. “And then all we need to do is guillotine it for the width, for example 1½ inches. There’s no need for slitting, which complicates things,” he says. “The machine is small, approximately 10 feet long, and it’s under $90,000, very low cost compared to the [larger] line that produces finished bars, which would be closer to $400,000.” The SlabForm DUO is geared to the artisan and specialty manufacturer, he notes.