Inspection & Detection

packaging

The BOTTOM LINE

- Upgraded systems ensure detection of foreign objects

- How to reduce false rejects

- New metal detection technologies

When it comes to new developments in inspection/detection equipment for the snack and bakery industry, consumer demand for variety is driving the need for equipment that is flexible enough to accommodate new product types, packaging materials, and package sizes. Flexibility is the key to allowing food processors to quickly change from one product recipe to another.

X-ray vision

X-ray, metal detection, checkweighing, sorting, and vision systems feature many upgrades.

Neal Lorenzi, Contributing Writer

The latest X-ray, metal detection, checkweighing, sorting, and vision systems reflect this trend. These upgraded systems allow bakery/snack producers to better detect small foreign objects, reduce false rejects, and handle a wide range of products to ensure maximum food safety.

For bakery and snack producers who are striving to achieve this goal, X-ray inspection and metal detection are complementary technologies, experts agree. “Metal detectors have always been a manufacturer’s first port of call as a cost-effective, low-maintenance way to pick up foreign matter in the food production process and they are still vital for food safety,” says Eric Garr, regional sales manager, Fortress Technology, Toronto. “However, X-ray also plays a critical role in food safety and should always be used as a complementary technology to metal detection.”

More food processors are asking for equipment that can detect smaller metal contaminants and soft contaminations as well as inspect incoming ingredients such as nuts and dried fruit. Simply put, an increased emphasis on food safety has producers seeking detection of all contaminants in their product, regardless of the size or the material.

“X-ray also plays a critical role in food safety and should always be used as a complementary technology to metal detection.”

— Eric Garr, regional sales manager, Fortress Technology

“While end-of-line inspection is typically the critical control point, inspection of incoming ingredients may offer benefits, such as protecting machinery and eliminating contaminants before they can be fragmented into pieces that may be too small for detection at end-of-line inspection points,” says Todd Grube, product manager for inspection systems, Heat and Control, Hayward, CA. “The latest metal detection and X-ray technologies make it possible for food processors to choose the most economical detection solution, depending on their products.”

There are many opportunities for contamination to occur before products arrive at a food processing plant. “Even with safety regulations in place, many plant workers don’t check items for contamination upon arrival,” says Ray Spurgeon, product manager for metal detection, Eriez, Erie, PA. “Proactive companies never assume complete cleanliness, so they install magnetic separation equipment and metal detectors at the beginning of their processes.” SF&WB

Bunting, Newton, KS, has introduced triple-frequency technology for its metal detectors, which allows the product learning process to calculate the best frequency for a product. It also returns the sensitivity achievable at each frequency, according to Barry Voorhees, metal detection product manager. “If you have products with different properties, it allows the proper frequency to be utilized for each one. It also allows the user to concentrate on one contamination material type over another when ‘learning’ the products.”

Company:

Bunting

FEATURED PRODUCT:

meTRON 07 CI coil Metal Detector

What advances in inspection/detection do manufacturers see happening in the near future? The Internet of Things (IoT) will play a big role, according to Ray Spurgeon, product manager for metal detection. “For food processors, IoT devices can transmit useful information across multiple process lines and provide valuable data from connected metal detectors. There is significant automation in today’s facilities and consequently fewer people on the production line. Given the lack of personnel, today’s metal detection equipment needs to be smart and proactive. The IoT can help make this happen.”

Company:

Eriez

FEATURED PRODUCT:

Xtreme Metal Detector

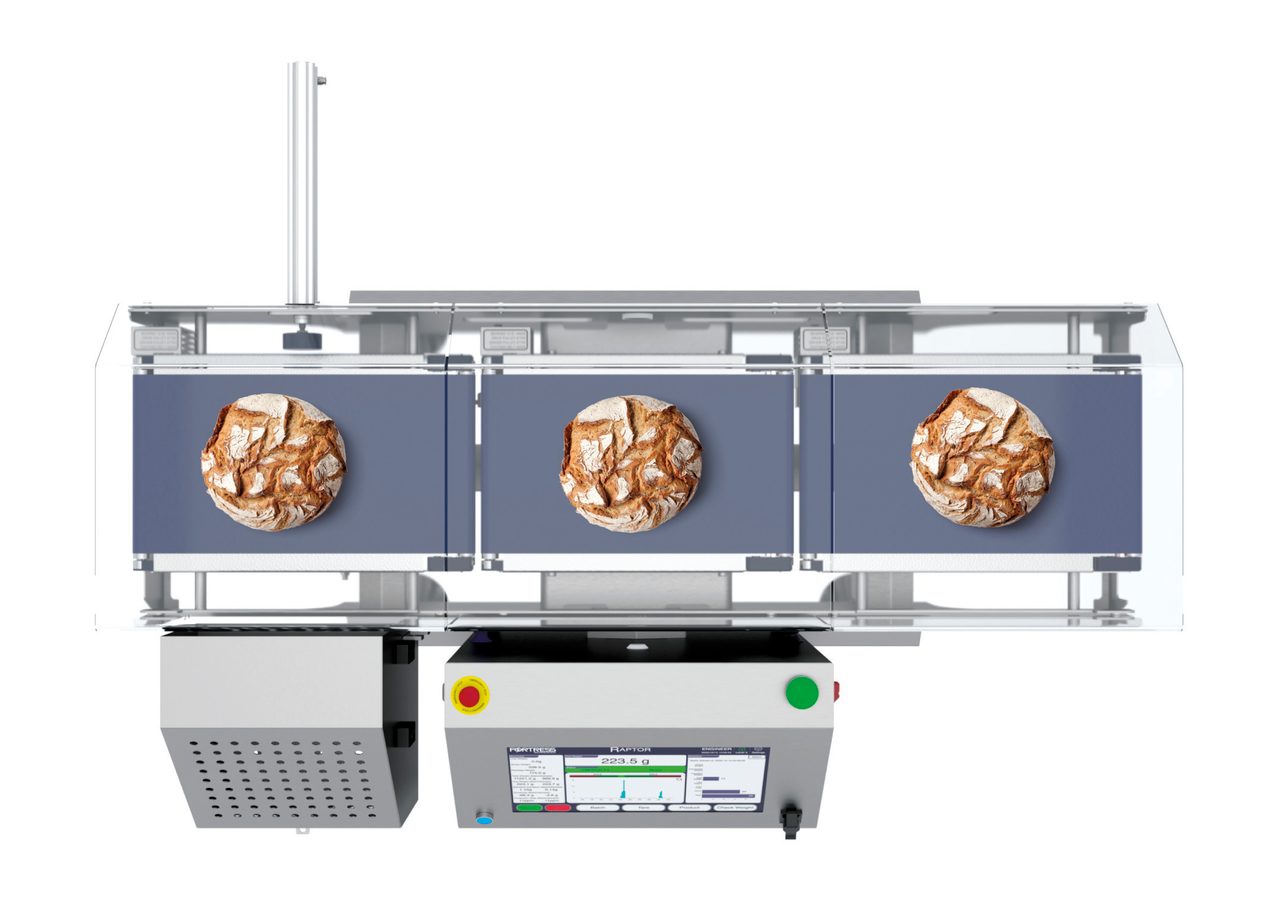

Fortress Technology recently introduced two Raptor Checkweighing systems: a single-frame, standalone checkweigher and an XL case weighing system for ingredient and bulk applications, such as flour sacks weighing up to 25 kilograms. A heavy duty 50-kilogram version also is available. Operating as a standalone product feed and pack weighing unit, the Raptor’s modular electronics suite allows for full integration with a Fortress metal detector to create a combination system, according to Eric Garr, regional sales manager.

Also, the Raptor checkweighing series incorporates a pivoting end roller conveyor concept, which overcomes the challenge of loosening belt tension when sanitizing food inspection equipment. “Featuring quick disassembly of the deck, motor and rollers, the conveyor saves time and labor and provides hygiene peace of mind,” Garr notes. “During the sanitization process, machine operators simply disconnect the conveyor motor and lift out the entire assembly.”

Company:

Fortress Technology

FEATURED PRODUCT:

Raptor Checkweighers

New in the area of X-ray inspection, Heat and Control offers the Ishida IX-GN Series X-ray inspection system, which features seven-step image analysis technology. Features include defect inspection, a masking feature which factors in individual product attributes that may cause false positives, and weight estimation. “The IX-GN Series offers versatile detection settings that cater exactly to inspection requirements,” says Todd Grube, product manager, inspection systems. “Ishida also offers the IX-EN Series X-ray inspection system, which provides reliable inspection for basic level applications with a lower voltage X-ray tube.”

Company:

Heat and Control

FEATURED PRODUCT:

Ishida IX-GN Series X-ray

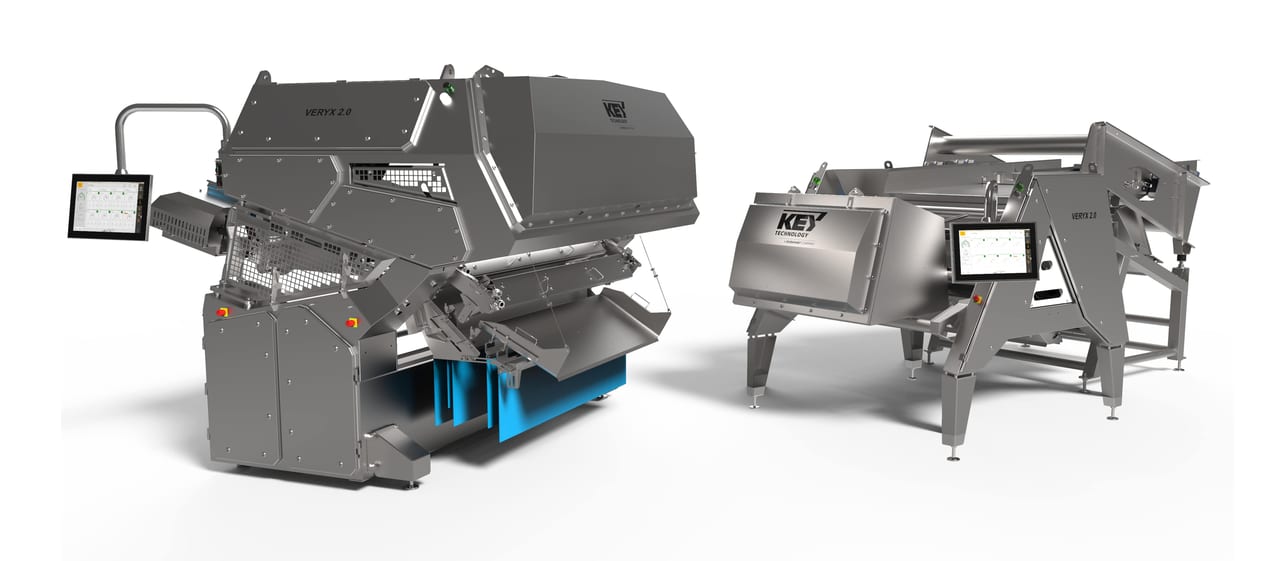

Key Technology, Walla Walla, WA, has introduced the VERYX 2.0 line of digital sorters. Featuring next-generation LED illumination, enhanced laser scanner technology and new software driven by artificial intelligence, the sorters reduce operating costs and improve the accuracy of foreign matter (FM) and defect removal to optimize product quality and maximize yield, according to Marco Azzaretti, director of marketing.

“VERYX 2.0 also includes Key’s enhanced laser scanner technology,” Azzaretti continues. “New digital receivers produce the highest resolution available while delivering a signal that is more accurate and consistent. As a result, VERYX 2.0 laser scanners create more contrast to better differentiate various types of objects, which enables more precise FM and defect removal while reducing good product loss and improving yield.”

Company:

Key Technology

FEATURED PRODUCT:

VERYX 2.0 Digital Sorter

New vision systems are making inroads. They are now being used throughout the production line—after forming, before and after the oven, and final inspection, according to Erica Vannini, customer service manager at KPM Analytics, Westborough, MA. “The data they gather can be used for controlling feedback loops and making decisions to improve processes. With this information, users can act quickly to control and improve production processes.”

KPM Analytics recently introduced the TheiaVu Series Compact Vision Inspection System, a benchtop analyzer for bakery/snack producers that provides fast, accurate and consistent measurement of size, shape, color, and toppings, thus ensuring high-level product quality, according to Jon Gilchrist, applications engineering manager. “The system provides a broad range of data for testing, research, quality assurance and final product inspection. An optional feature is crumb analysis, which produces high-quality images and data of the internal crumb structure of bread products.”

Company:

KPM Analytics

FEATURED PRODUCT:

TheiaVu Series Compact Vision Inspection System

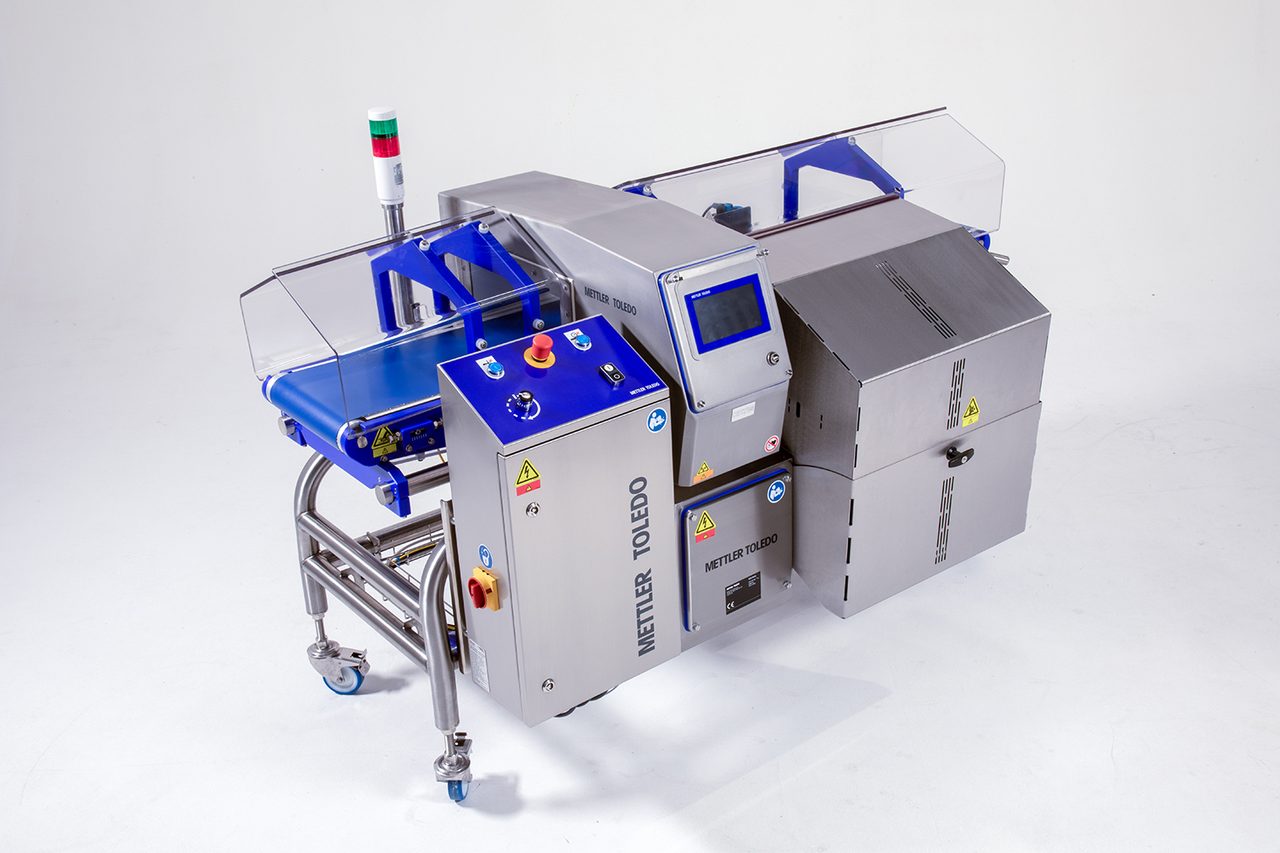

The entry level M31R Standard Line metal detector from Mettler-Toledo Safeline, Columbus, OH, delivers versatile and reliable inspection to help meet global food safety standards in the bakery/snack industry, according to Camilo Sanchez, product manager for metal detection. “With features such as a 7-inch color touchscreen with intuitive software and three discrete operating frequencies, this entry-level machine can easily be upgraded in the future. The M31R is the perfect choice for cost-sensitive applications.”

Company:

Mettler-Toledo

FEATURED PRODUCT:

M31R Standard Line Metal Detector

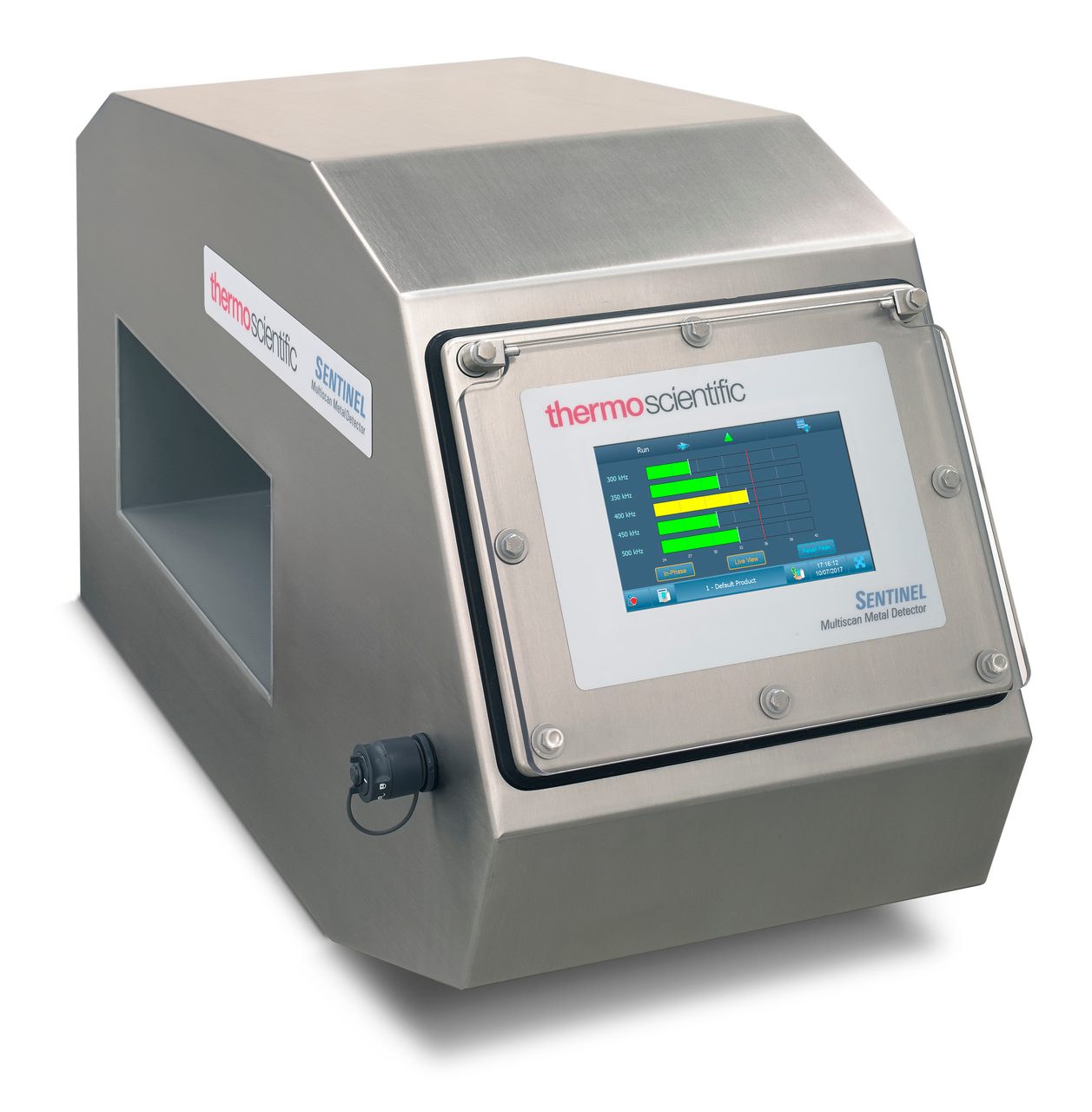

Helping bakery/snack producers in their quest to achieve food safety, new multi-scan metal detectors can inspect products using multiple frequencies, instead of the traditional single frequency. “This enhanced capability allows higher detection probability since most contaminants show responses at various frequencies,” says Yuan Chloe Lu, product application specialist, product inspection, Thermo Fisher Scientific, Waltham, MA. “Even if the contaminant signal at a specific frequency is low, it can still be detected on a different frequency, therefore ensuring detection.”

Thermo Fisher Scientific has introduced the five-frequency Thermo Scientific Sentinel 5000 Multiscan Metal Detector. It comes equipped with a user-friendly Autolearn software feature that can help users set up a product in less than 10 minutes. The software actually “learns” the product signal and background noise while products pass through the metal detector; it then determines the best frequencies to use for this type of product and the smallest contaminant size it can detect. “This Autolearn setup speeds up the training period of new employees,” Lu says.

Company:

Thermo Fisher Scientific

FEATURED PRODUCT:

Sentinel 5000 Multiscan Metal Detector

Yamato Corp., Grafton, WI, offers the Checkweigher J Series, which features force balance technology. Suitable for inspecting small packages, pillow packs and pouches, the machine provides accuracy down to +/-0.015g at speeds up to 450ppm, according to James Lubow, product manager. It also features an air blast rejection system and tool-less conveyor removal.