Mixers

PROCESSING

The BOTTOM LINE

- Producers want consistency, temperature control, and efficiency in mixers

- Snack and bakery staff also are looking for flexibility in controls

- Ease of cleaning and hygienic design are top priorities

Mixing things up

Snack and bakery producers seek mixers that offer consistency, control, and hygienic design.

Ed Finkel, Contributing Writer

Top of mind for snack food and wholesale bakery companies who in the market for new or improved mixers are qualities like consistency, temperature control, and the ability to distribute raw materials fast and efficiently.

Producer perspective

Aron Pobereskin—head of innovation for Redbud Brands, which produces Cheddies crackers—says that he’s hoping to gain as much control and consistency as possible, given that challenges inherent around variables like temperature, humidity, and raw materials.

“I dream all day about what I want: multiple hoppers, the ability to heat and cool, multiple nozzles, the largest batch size possible, a mixer that has a high capability for dispersion, and high shear, to get the process done quickly and efficiently.”

— Aron Pobereskin, head of innovation, Redbud Brands

“What that means for a mixer is that we want to distribute raw materials quickly, efficiently, and evenly as best we can,” he says. “Raw materials are going to have introduction to water and will be competing for control. If they’re not distributed quickly and evenly, it’s anyone’s guess which is going to take complete control of that water. We want to make sure the hydration is even, so that each one can act in its full function. Each one affects the texture, consistency, taste, the way moisture migrates, and the integrity of the end product.”

Pobereskin wants a mixer that moves the dry product quickly and that can apply water across as vast a surface area, as possible. “If it has one spigot or valve, I’d rather have 10—I’d rather have 100,” he says, perhaps somewhat wishfully. “I’d rather every particle have the best opportunity to come into contact with water.”

Next, Pobereskin focuses on temperature control. “The way the cheese interacts with raw materials and water is completely dependent on temperature,” he relates. “If it’s too hot, fat and protein can break down too quickly, separate, and create an oily or greasy dough. If it’s too cold, that happens too slowly, and it requires greater effort to break down. The flour becomes over-mixed, and we have a tough dough.”

Redbud Brands also would like a mixer that has a variety of settings, Pobereskin reveals. “I would love to have, in the future, a piece of equipment where I can regulate temperature after the introduction of raw materials, whether by increasing shear and torque, or by introducing a heating element,” he says. “Especially as the seasons change; in the summer, you need less water, and water that’s cooler, so that other properties are maintained well. In the winter, that’s going to be too cold and too stiff. Controlling that internally would be advantageous.”

Mixers with multiple hoppers remove the human element from the equation, to some extent, with pre-blended ingredients entered into one hopper, and liquid from another, at a controlled rate to come in contact in a more intentional manner, Pobereskin reports.

But as a smaller brand that works with contract manufacturers, he says, “What they have is what they have. I dream all day about what I want: multiple hoppers, the ability to heat and cool, multiple nozzles, the largest batch size possible, a mixer that has a high capability for dispersion, and high shear, to get the process done quickly and efficiently. My wishes are kind of simple, and the continuing trends are efficiency and consistency.”

Single-arm mixers can result in residual powders and dry materials falling off once the dough is fully mixed, which Redbud wouldn’t want its contractors to try to incorporate at the last minute into otherwise homogenous dough, Pobereskin remarks. That makes a mixer with an internal scraper that’s continuously blending an important feature, to cut down on waste.

“When producing millions of pounds a year, it really adds up,” he says. “A complex piece of equipment to fulfill a simple purpose could have huge implications. All of these things rely on the equipment to minimize loss, and when that’s possible, we can sell products at a better price to consumers, as well. That could be as simple as having a scraper inside.”

Courtesy of Rapidojet

A self-cleaning unit also would be a nice-to-have, Pobereskin adds. “A mixer that is efficient at cleaning itself, adding water and detergent, without too much leaking.”

Focus on hygiene

Ronald Falkenberg, regional sales director, USA and Canada, Diosna, says his customers are most interested in hygienic designs with easy washdown execution and in automation due to the lack of available employees, including automated fermentation systems.

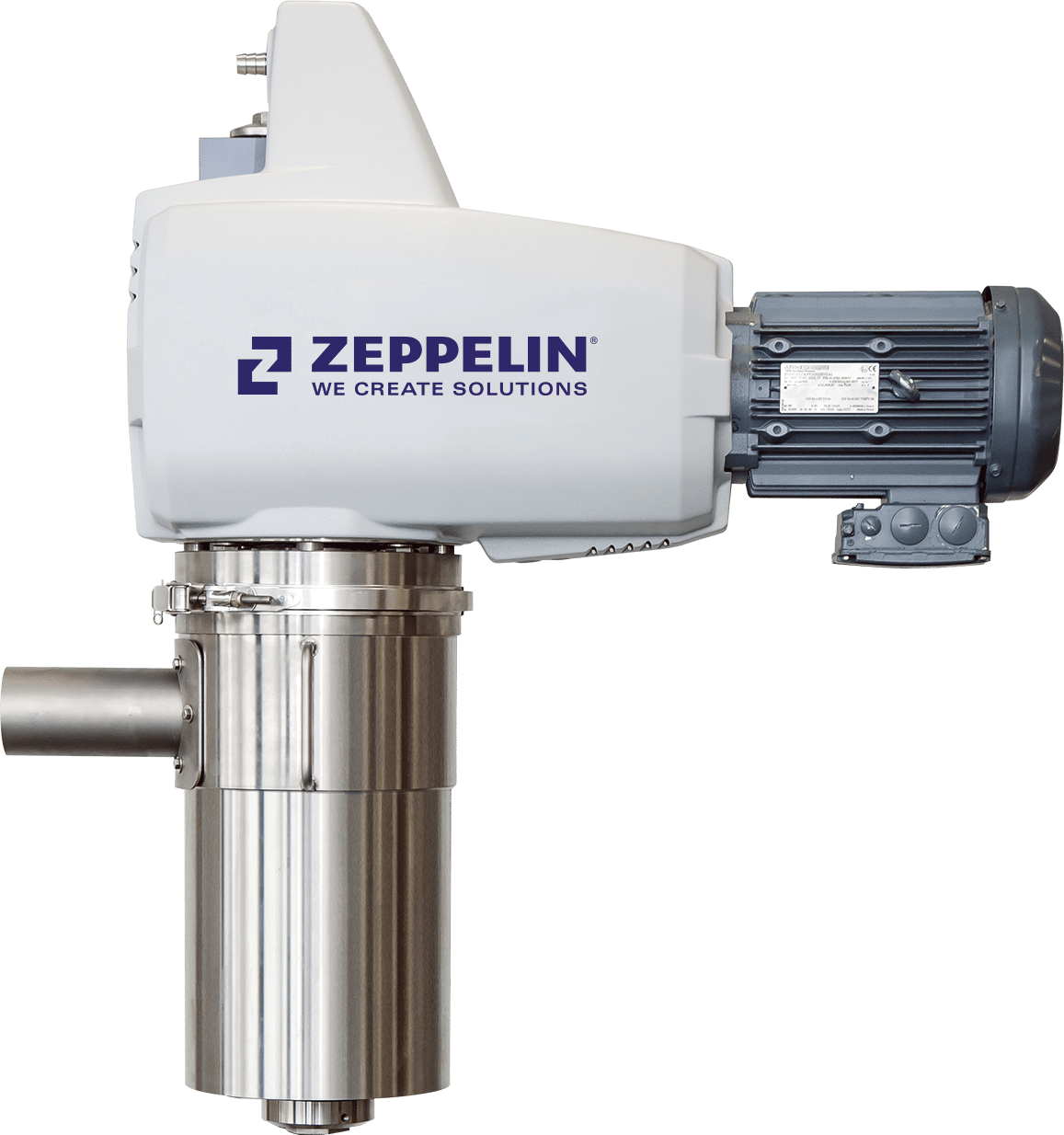

Customers of Zeppelin Systems USA are most focused on consistency and temperature control, says David Rodrigues, application manager. The former revolves around continuous mixing with excellent dosing control of different ingredients into the mixer through a batching process that tracks performance and self-corrects as needed, he says. Temperature control involves both the liquid ingredients like water and solid ingredients like shortening, to ensure the temperature of the dough continuously holds in the desired range during mixing.

The baking industry has moved toward straight dough, which works well for cookies but not so much for breads and buns. Further, the field has it seen spike in the use of whole grains due to the health benefits, which often involves infusing bran, comments Ken Schwenger, president of Bakery Concepts International, manufacturer of Rapidojet. He sees the potential for a resurgence of continuous mixing so long as the mixer eliminates negatives currently associated with that type of process, in terms of energy, coolant, square footage needed, and capital expenditures.

Labor challenges

The biggest complaint Schwenger hears from commercial bakeries at the moment is finding enough labor to run their various processes. “It’s tough to attain [workers], and it’s even tougher to retain them,” he says. Other concerns include equipment usable for as many types of applications as possible, sustainability around the use of water and energy, and equipment that provides ease of sanitation—which also can improve worker safety if it involves less chemical usage, Schwenger adds.

Courtesy of Zeppelin

In terms of product trends, Schwenger points to the quickly growing market segment of tortillas, along with masa for corn chips or corn wraps. Rodriguez of Zeppelin Systems also mentions tortilla dough as an expanding market, along with needs for pizza dough, especially in the realm of continuous mixing. Falkenberg of Diosna says premium breads like sourdoughs are becoming mainstream. “Even in the big players, it’s everywhere,” he says. SF&WB