And, Bobyk adds, equipment manufacturers, much like producers, “must continually keep their finger on the pulse and often times, react to sudden consumer demands.”

Operational data

Roesler says collecting and analyzing operational data can help producers achieve and maintain consistent product and improve quality, particularly in continuous mixing applications.

“Gathering of data is a mainstay of continuous mixing,” he remarks. “While collected data can be used to ensure quality, in the case of continuous mixing the data can be used to make process intervention and corrections without the involvement of the operator.”

Hagedorn says in order for a bakery operation to succeed, dough-handling equipment (and other technology in a production environment) need to adapt rapidly, which can be made possible through integration of tech that facilitates advanced monitoring, control, and secure communication.

“At Handtmann, this adaptability is not a big leap but has been designed into our development processes for decades; our Handtmann R&D, engineering and manufacturing teams continuously design and implement a very wide range of adaptable digital solutions to better monitor parameters and control processes as standard equipment in our technologies,” he notes.

Hagedorn adds that keeping tabs on such data can help current equipment and the producers employing it “meet tomorrow’s challenges with regular software updates and system innovations.

Flexibility

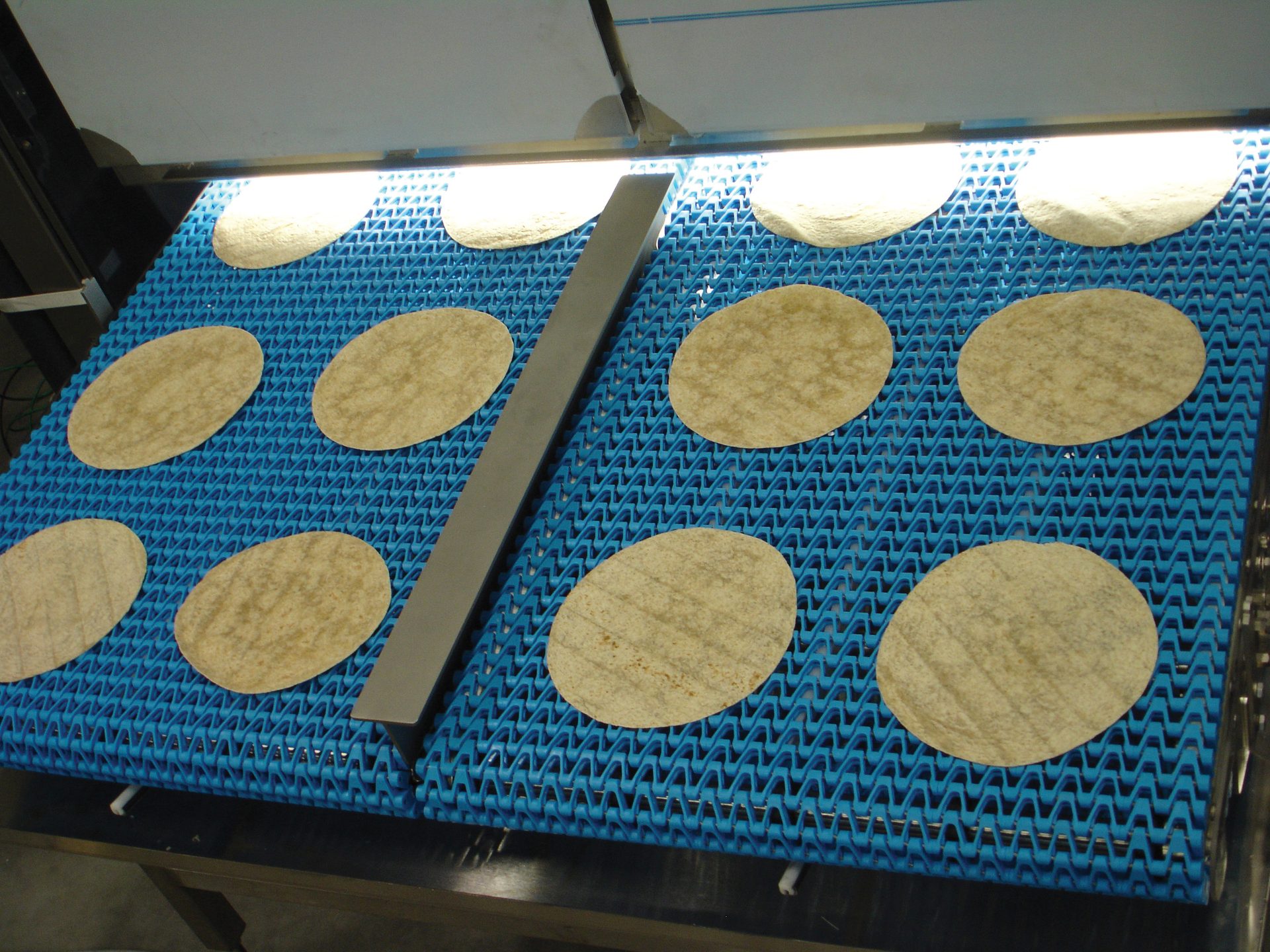

Producers increasingly demand their equipment be able to handle different types of product, and adjust to changes yet to come. Roesler says equipment producers like Reading Bakery Systems are ready to deliver.

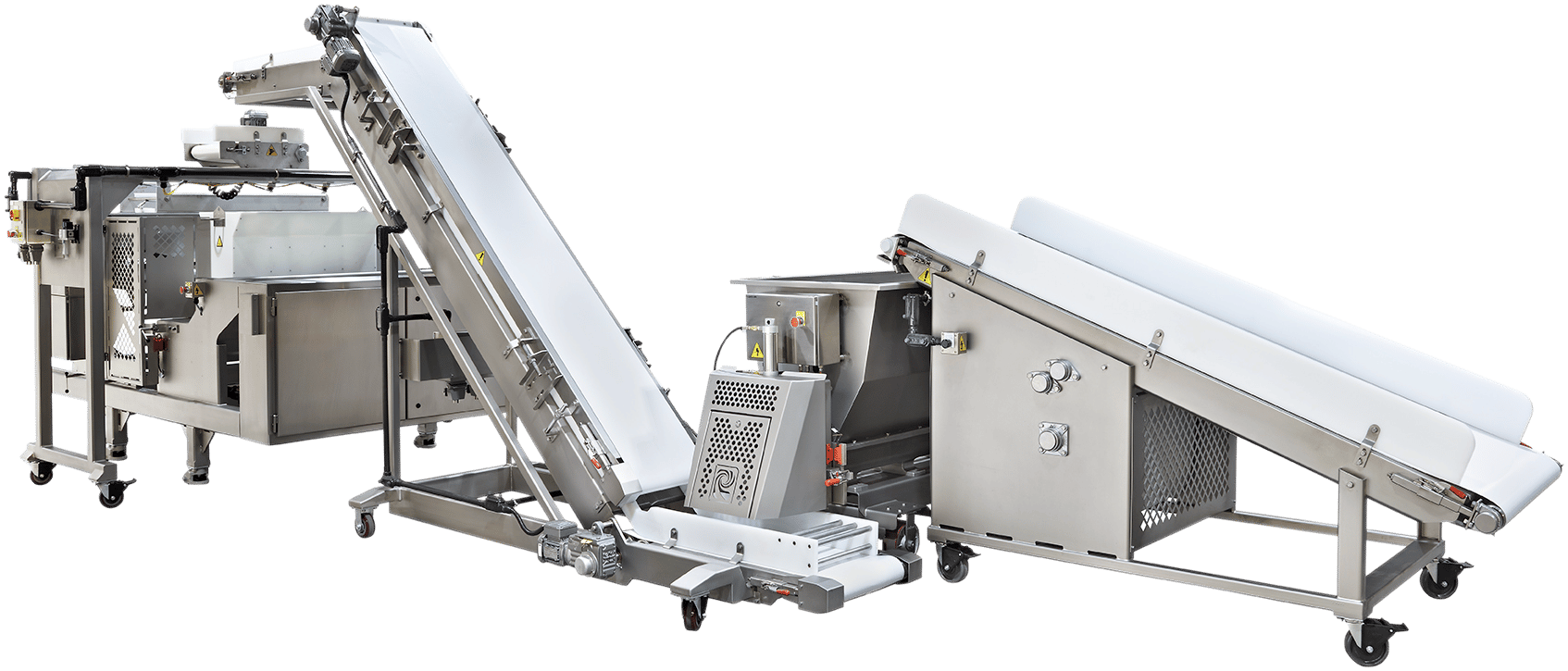

“RBS dough handling equipment is versatile and can handle any type of dough,” he comments. “Laytime conveyors allow dough to sit and ferment if required, or we can create automated dough trough systems for doughs that require many hours of fermentation. The mixer discharge conveyors can be used for multiple dough types and can transport dough to any downstream equipment.”

Bobyk remarks that the public’s hunger for new, different bakery items drives the need for innovative bakery technologies.

“As long as consumer demand is around, equipment manufacturers will keep developing new technologies to accommodate those needs,” he says.

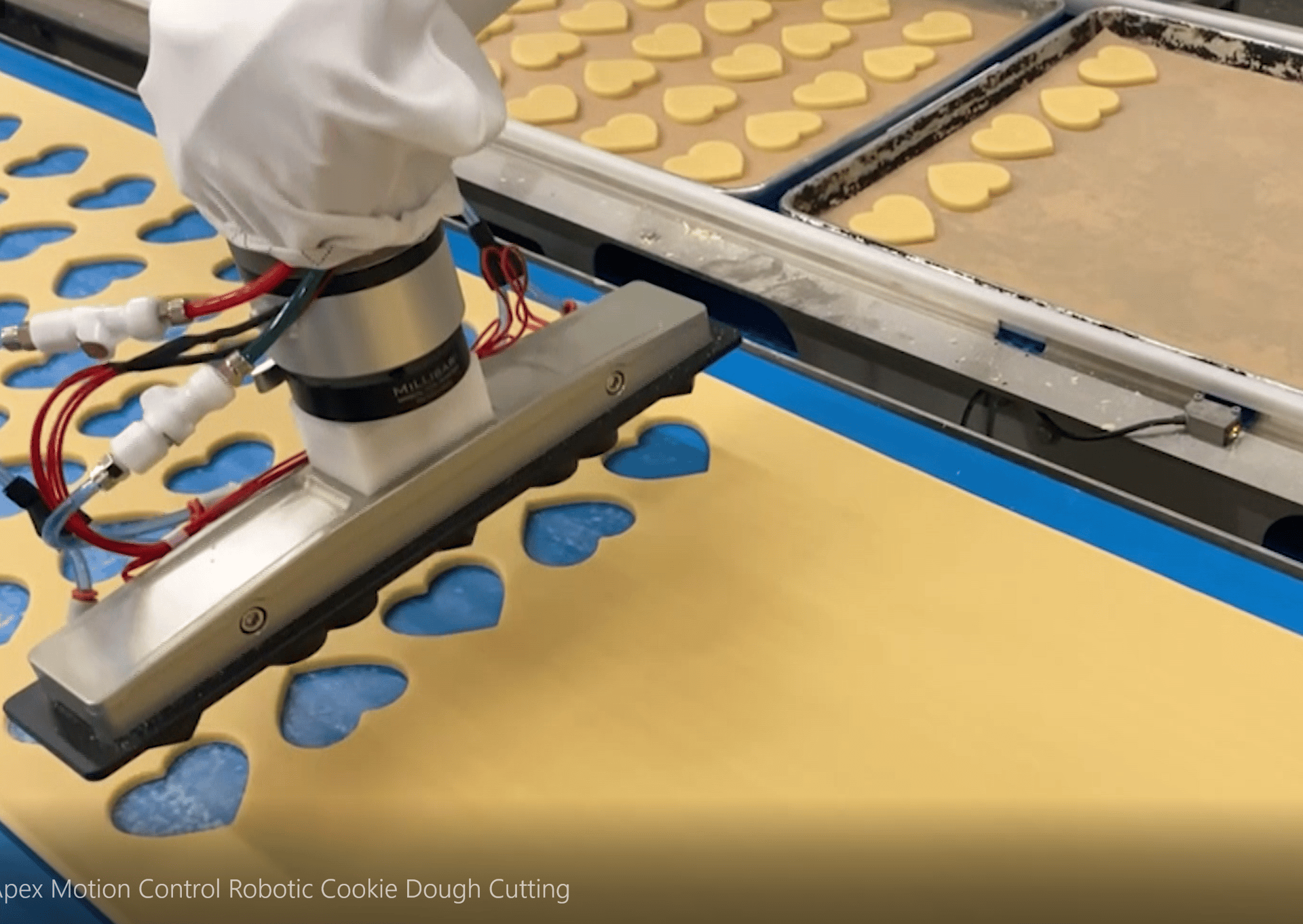

Labor and automation

Labor shortages were a pressing issue before the pandemic; COVID-19 has made such concerns even more of a headache. According to Bobyk, workforce woes inevitably will continue, necessitating increased reliance on automation.