Shaffer Manufacturing, Urbana, Ohio, which is now a subsidiary of the French company LINXIS Group, also hears from customers who want to automate and simplify their processes so they need fewer people, says Andrew McGhie, director of sales. “Sanitation is related to that as well—they want to be able to clean the mixers easily with minimal intervention by the operators because they don’t have the people,” he says.

Ideally, they want high-pressure cleaning-in-place to ensure that allergens are properly cleaned as quickly as possible for gluten-free formulations, McGhie says. Customers also are looking to collect and share data to monitoring machinery processes, he says, and they would like mixers to come with high-efficiency motors that use less electricity, save money and are more environmentally friendly—which Shaffer, in turn, has been asking of its vendors for these parts.

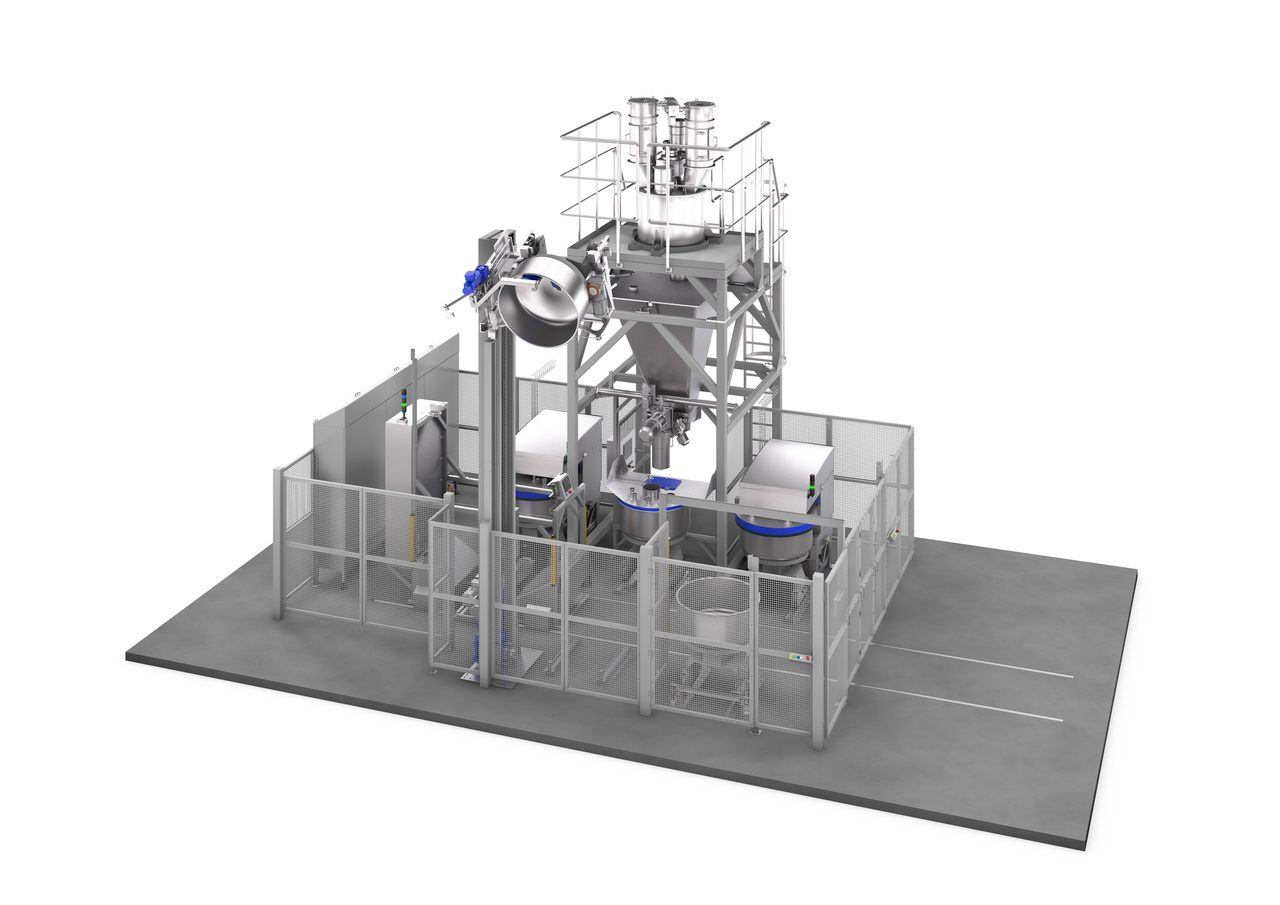

Shaffer has been working regularly with customers to more thoroughly automate their existing equipment, McGhie says. “We need to be able to dump the dough out, automatically, without anybody touching it, into the chunker, the dough pump, or wherever it’s going next,” he says.

Where standard mixers have about a 120-degree tilt, Shaffer has been moving toward 160- or even 180-degree “over-tilt” designs so that the dough discharges automatically, even if it’s sticky, McGhie says. The company also has been automating its machines on the ingredient handling side so that the next batch starts when the current one ends. “The last two years, that’s become huge because people are so hard to get and hold onto,” he says.

Customers also have been asking Shaffer for higher-capacity bagel mixers, which presents a challenge given that bagel dough is particularly stiff, with low water absorption, and thus generates quite a bit of torque inside the mixer, McGhie says. “It’s like mixing concrete,” he says. “Because of the torque and high horsepower required, the structural columns, the tubular stainless steel bowl ends and agitator ends all have to be thicker and stronger.”

In the past, the company hadn’t gone much beyond 2,000-pound machines, and even those customers didn’t typically try to handle more than 1,300 pounds of dough at once. But Shaffer is now handling mixers that can handle up to 2,800 pounds of bagel dough, and customers are exceeding 2,000 pounds in their runs, McGhie says. “We previously had stepped away from projects like that and said, ‘You don’t want to do that; you should have two smaller mixers,’ ” he says. “But customers kept pushing us.”