Automated flour fillers are another popular innovation that helps companies reduce staffing, especially useful during a tight labor market, Hagedorn notes. “It automatically monitors the flour hoppers and fills them, so there’s no longer a person walking up and down the laminating line,” he says. “That can be a full-time job for somebody.”

Customers of Baker Perkins, Grand Rapids, MI, and Peterborough, UK, in the biscuit and cracker industry are asking for non-standard equipment that can handle unconventional ingredients and products, according to Keith Graham, business development manager.

“As manufacturers seek innovation in highly competitive situations, attention-grabbing twin-layer crackers involving two distinctive tastes, or two-color products, have become an option,” he says. “They are achieved either by one sheeting machine with a split hopper, or two sheeters mounted one above the other. The two distinct doughs are merged into a compacted sheet ready for the gauge rolls.”

Another choice customers sometimes make is a twin-layer sweet biscuit, with a filling baked between two sheets of dough, such as a Garibaldi biscuit with currants, or a chocolate or praline paste, Graham says. “To add interest and variety, crackers and baked snacks are being developed using non-wheat flours based on lentils, pulses, or chickpeas and from cauliflower or potato dough,” he says. “These are often used to achieve gluten-free products and may also be perceived as being healthier. The possibility of original flavors or textures is another motive.”

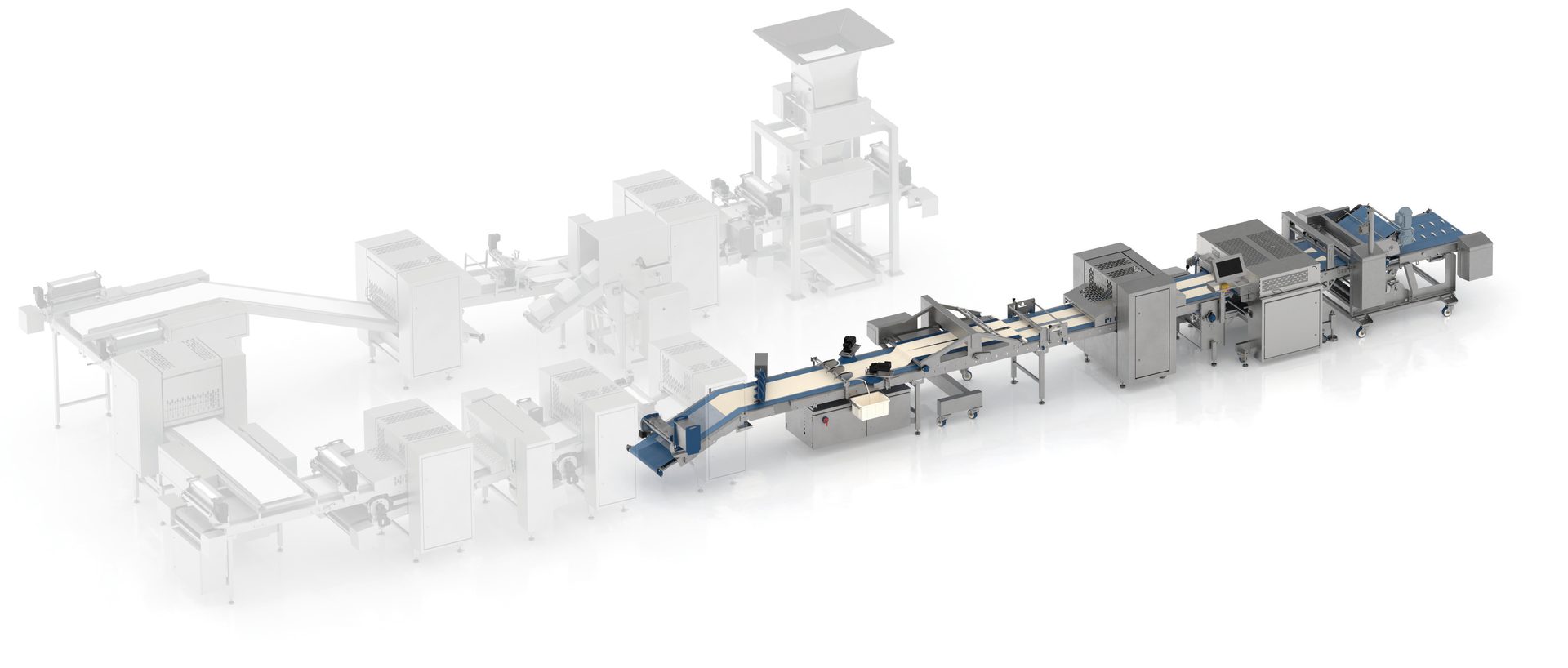

Flexibility, speed-to-market, and automation are top of mind for customers of Rademaker USA, Hudson, OH, according to Nick Magistrelli, vice president of sales. When it comes to flexibility, customers typically don’t want a one-size-fits-all line—they want to be able to “take into consideration a variety of processes,” he says. “To justify this investment, customers don’t want to get pigeon-holed. It makes them a lot more confident when they can pivot down the road and produce new SKUs and fill different needs.”

Speed-to-market is another consideration, although sometimes customers’ timeframes outstrip the manufacturer’s ability to produce, and they need to consider the used market instead, Magistrelli says. “Especially in today’s world, where everybody has ongoing and, in many cases, growing supply-chain issues,” he says. “When your clients can deliver in that speed-to-market scenario, that provides them an advantage over the folks on the other side of the table.”