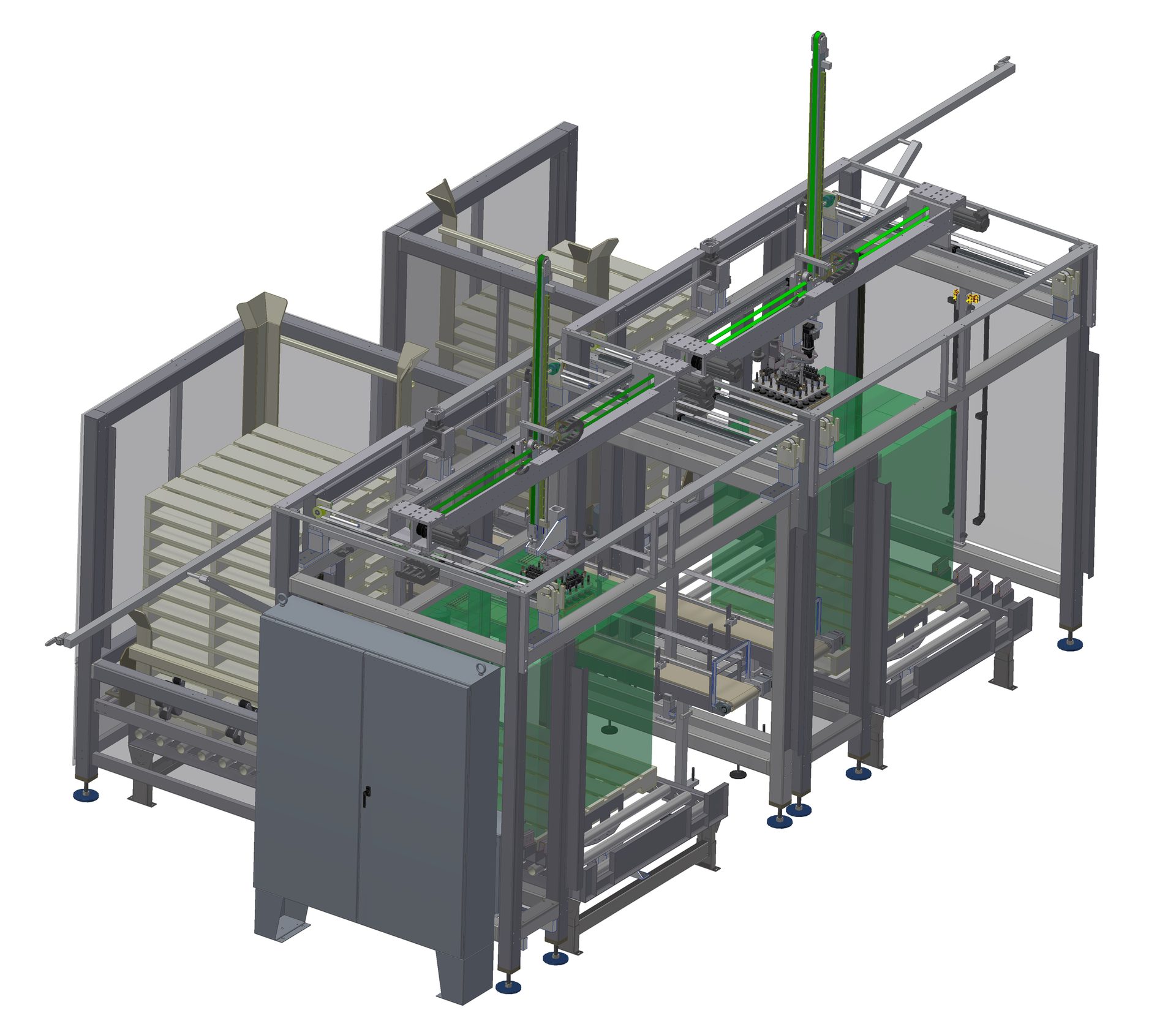

A-B-C Packaging Machine Corp., Tarpon Springs, FL, recently introduced a compact palletizer, the Model 72AN, designed to fit in production areas where space is limited. It is fully automatic and offers all the flexibility and efficiencies of A-B-C’s larger models, but occupies up to 30% less floor space than other floor-level palletizers, the company reports.

Another area of recent advancement: all A-B-C palletizers are now smart machines that offer connectivity to plant-wide control. All operating data, from the drives all the way down to the component and sensor level, can be readily accessed at the HMI as well as the factory control station, according to Bryan Sinicrope, vice president of marketing and integrator sales.

A-B-C palletizers can configure packages in each layer to have “graphics or labels out.” This can increase efficiency at the warehouse or retail outlet, as product contents and ship dates are easily obtained via a quick scan. “Also, our pallet builder enables configuration of new pallet and layer configurations at the HMI,” Sinicrope says. “We can palletize four patterns within one pallet, offering enhanced flexibility for snack and bakery producers who are shipping to retail outlets.”