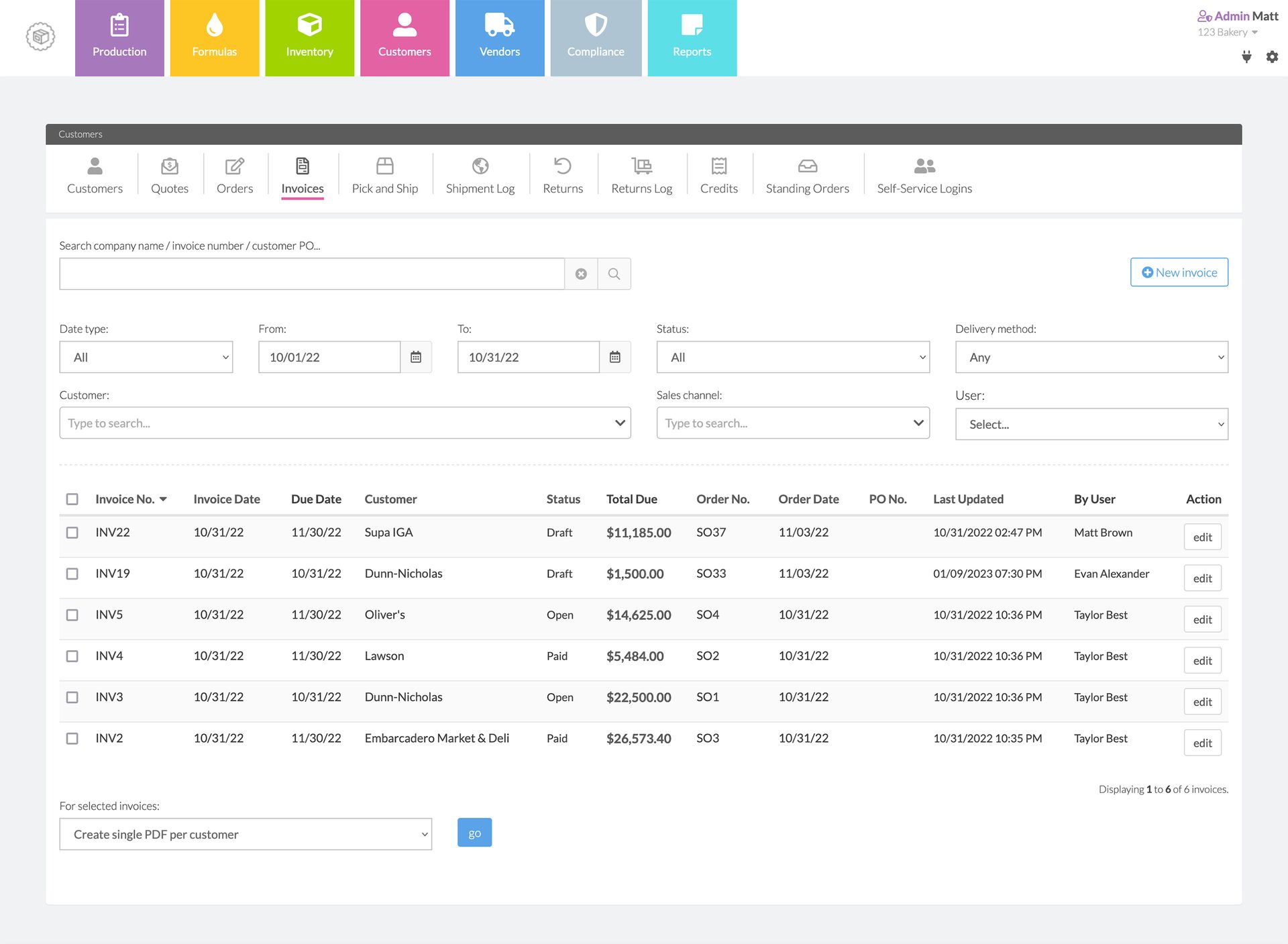

• Imported files

• Can organize orders by delivery route

• Batch-printing invoices or combining into single PDF

• Quick product returns if needed

“Modern software needs to look and feel like the apps that users are accustomed to using in their off-work hours. Their work software could have tons of functionality, but if the users can’t access that functionality, it is useless. Ultimately, great software tools will make the users’ job easier,” Brown predicts.

Ash Matthews, quality control, development, FlexiBake, Vancouver, BC, says that modern customers know what they want: fast, easy, and transparent.

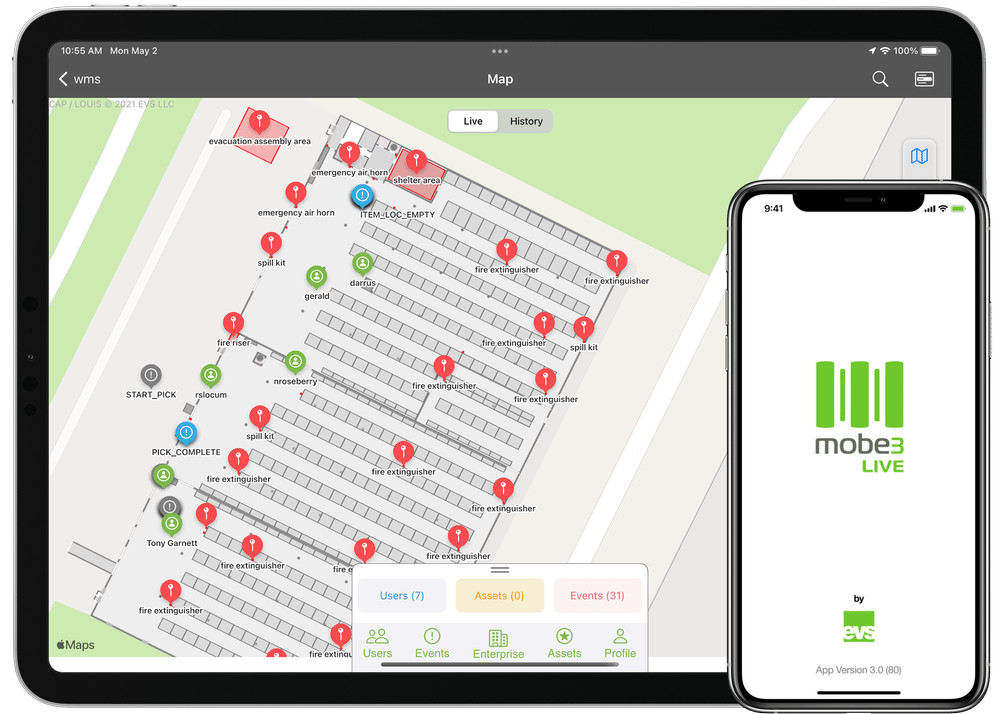

“Moving to digital tools is a great way for businesses not only to keep up with these expectations, but increase efficiency and cut costs. Our MetriX DSD app allows companies to reduce or entirely eliminate paper invoices and manual data entry by moving the delivery process onto a handheld device. Drivers can update invoices to reflect what was delivered, record stale returns and issue credits for them, report payments taken, and take signature on the delivery,” she explains.

Using a data connection, the app can sync immediately, allowing for digital invoices to be sent to the client and their account in FlexiBake’s enterprise resource planning system is updated immediately with the new information in real time, Matthews says.

Ellis notes that the availability of mobile devices that can scan and connect to small, portable printers has made bakery deliveries much easier than before.

“With mobile devices and cloud-based software, drivers can view and make changes with their customers, rather than waiting until they get back to the office,” he comments. “We’ve found this leads to better responsiveness to customer needs and less wasted product or delivery runs, and this ultimately helps our bakery users keep delivery costs lower.” SF&WB