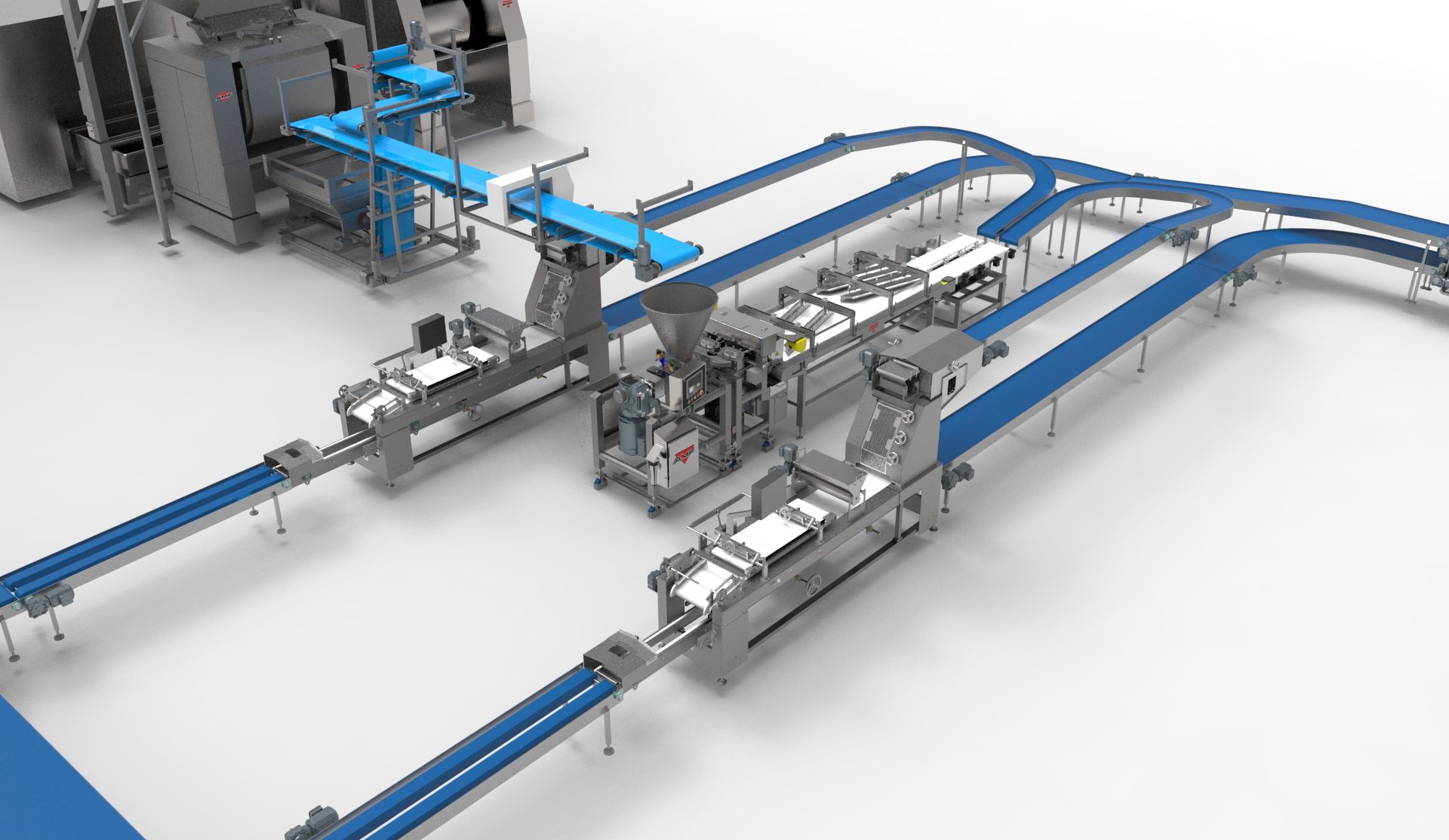

The use of robotic automation where “the software is the magic” is a calling card of Apex Motion Control, Surrey, British Columbia, which works with a number of snack and bakery companies to round and form snack and bakery products.

For example, in one scenario involving pizza balls, “The dough is formed and comes down a conveyor,” says Jamie Bobyk, marketing manager for Apex. “How do they deal with putting it on trays and racks and going from there? Instead of having a person manually lifting trays, standing and waiting there, they can repurpose the staff and put a cobot there.” Once the rack is filled, a person takes it and moves it into the system, he says.

In another, similar use-case, cookie dough comes down into a hopper, it’s cut into “pucks,” and the tray is fed on one end with Apex’s automated tray feeder. At the end of the line, a “baker-bot” with a clamp takes it off and puts it into the rack, Bobyk says. “Once the one rack is filled, it will automatically sense that and move a new rack into place,” he says. “It does this all day.”

With such a semi-autonomous system, a bakery needs just a single person to check up on things, move a couple racks here and there, and keep busy with other tasks, Bobyk says. “We’ve done work with companies in the U.S. that have bagel lines, with a baker-bot at the end of the pan, catching the formed bagels, moving them horizontally or vertically,” he says. “And once you have eight or 10 bagels on that pan, it moves it from there to get proofed and fried or boiled—however they handle the bagels.”