Seasoning and coating equipment

Tech & Techniques

The BOTTOM LINE

- Top concerns include sanitation, ease of operation, and flexibility

- Ease of setup and adjustment appeal to producers

- Other interests include avoiding product breakage and waste

Get it covered

Bakers and snack makers want seasoning and coating equipment that is reliable, flexible, and easy to operate.

Ed Finkel, Contributing Writer

Accuracy, reliability, flexibility, automation, ease of sanitation, and ease of operation are a sprinkling of the features and benefits that manufacturers of seasoning and coating systems say their customers most commonly request in new or improved equipment and technology.

Key priorities

Accuracy, sanitation, and reliability are the top watchwords for customers of General Oil Equipment Co. (GOE), according to Norm Searle, who handles sales and marketing for the company. Regarding the first of those, he says, “Everybody wants to make sure they’re not giving away product, and that they’re meeting their labeling requirements. The cost of the oils and the application of the oils and the slurries, if they’re not on the mark, you have bad product.”

Courtesy of General Oil Equipment Co. (GOE)

Courtesy of Delkor Systems

Delkor Systems plans to introduce a new generation of Combo-line Bread Case Packers designed as an all-in-one solution for single-use shippers and reusable trays in 2025. “Producers can switch between corrugated (one way) shippers and bread tray formats in the same machine,” says Dale Andersen, president and CEO. “Retailers are moving away from direct store distribution (DSD) trays and into corrugated cases due to the challenges and costs involved.”

Delkor Systems recently introduced Smart-Lock, which streamlines packaging size adjustments using a linear bearing slide, LED-based feedback and an automatic locking system. It reportedly eliminates the need for rotary counters, allowing precise, manual adjustments with minimal effort. “It is three times faster, more accurate and designed to virtually eliminate operator errors,” Andersen notes.

“Customers want conveyor belts that can be cleaned more easily.”

— Rudy Sanchez, food handling product manager, Key Technology

When it comes to sanitation, Searle’s admonition is, “If it’s in the plant, it’s in the food. They don’t want to find carryover from prior runs. They don’t want to find a missed spot from when the cleaning folks came through. The drive is toward making a sanitary machine.”

In the current automated environment, Searle adds, operators are handling the verification process more than the cleaning itself: “While the machine is going through that cleaning cycle, it’s unattended.”

And, ramping up reliability means moving away from tiny orifices to convey oils or slurries, Searle remarks.

“A slurry with any type of inclusions would never pass through [smaller] orifices,” he says. “There will be debris coming off the product that will fall into the lower area of the spraying machine. We screen that prior to it going into a reservoir to make sure that any larger pieces that could plug up an open orifice, like we use, is kept out of the reservoir.”

Through inline flow monitoring, companies can measure by volume what’s going through a line and increase or decrease the speed of the pumps if they see a variance, to maintain the desired amount of seasoning or coating application, Searle observes. “The objective is to get an even distribution across the entire width of the spray, and to do so reliably.

In terms of product trends, GOE has seen new liquids and slurries that have “mind-boggling” viscosities, Searle notes.

“It’s almost like applying a powder,” he says. “If you’re going to take a liquid and add some of these super-flavors to them and pieces, chunks of vegetable, cheeses, whatever, and be able to spray it on, that creates a challenge and an opportunity.”

For example, many customers ask GOE to apply butter-garlic mixes to products like garlic bread and Texas toast, Searle shares.

“With garlic pieces, parsley, you can imagine the challenges to spray that,” he states. “The minute it stops flowing, these inclusions want to settle out. That in and of itself creates an opportunity and a challenge. How do you address that? It can easily get contained in some part of the reservoir and out of circulation. We’ve developed new pumping methods to meet the new product requirements.”

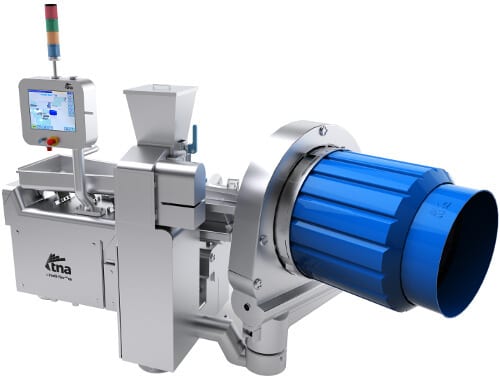

Customers of tna Solutions are moving toward healthier snacks, more unusual flavor profiles and smaller packages in the North American market, according to Steven RS Johnson, division sales manager for North America.

Courtesy of tna Solutions

“The look, smell, and taste of these products is really important,” Johnson states. “Combinations of sweet, sour, salty, bitter, umami base flavors, and the precisions with which they put those on, is important to success in the market. Systems that can handle wet or dry injections to add flavors to oil helps our [brand] customers achieve these unique flavor profiles that their [retail] customers are looking for.”

The trend toward smaller packaging puts more demand on machinery to be flexible, Johnson adds.

“There’s still a lot of demand for bigger bags, so systems have to be more flexible on capacity but still season with precision,” he says. “Our machines have to be able to accomplish those levels of seasoning performance that are expected so that our customer, the manufacturer, can be successful. The bag changes put more demands on the machines, too. It’s arguably easier to do higher volumes of products than when you get into smaller packaging.”

Robert Reiser, president of Wilevco, says his American customers all want to network their machines and get data out of them without the company’s assistance, although European customers still expect their machines to be serviced.

“[U.S. companies] don’t want to let us in to service the machine on that network, or monitor it, or do preventive maintenance,” he observes. “But they do want to have machines on their internal network so they can monitor, adjust and standardize, so you don’t have an operator who’s got a screen on every machine. It’s somebody up in a control tower.”

That aversion to outside access isn’t limited to customers of seasoning and coating machines, Reiser says, and it boils down to security concerns in the U.S.—which are not shared in Europe.

“They think we’re going to tell their competition what products they’re making and what hours they’re running,” he states of American companies. “They’re afraid we might put ransomware on there, both our own—you haven’t paid your bills, so we’re locking up your machine—or unintentionally, the Russians have gotten into our system and get into their system. They also think we would change pricing based on what we’re somehow able to monitor from their usage.”

Trends in snack food and bakery products don’t particularly drive the trends in what customers want from seasoning and coating machines, Reiser believes. “They want to make the same products, more efficiently and more consistently, and they want to make new products,” he states. “Sometimes, you make old products more efficiently and more consistently by changing how you do it, tweaking what you do on the plant … If you’re able to network it, you don’t need anybody down on the floor.”

Courtesy of Quantum Technical Services

Quantum Technical Services hears from customers mostly about automation, ease of sanitation and ease of operation, according to Tom Trost, sales manager: “Sanitation is a big deal; sanitary design with no exposed threads, a round bar so there’s no buildup, and requiring no tools.”

In terms of ease of automation, he adds, “We try to make that product as simple as possible. With targeted applicators, we can target specific spots—with trays of muffins, if you’re applying nuts, you can hit those individual pockets with no need for reclaim, which reduces waste.” And automation reduces costs of labor, which is difficult to find, anyway.

Trends in product toppings have partly driven these requests for features and benefits, Trost reports.

“With the variety of toppings that they want to apply to different SKUs, we try to make everything easy to switch out,” he says. “They want to run nuts one day, seeds another, so it has to be easy to change out the rotors on the dry ingredient applicator. You can run different toppings with the same machine, so flexibility is important, quick change-overs. You can do it with the same machine as opposed to multiple machines that they have to switch out.”

The right questions

When considering how to upgrade their seasoning and coating equipment, snack food and wholesale bakery companies should ask to see a demonstration, talk to customers of the manufacturer who have used the equipment, and find out how available parts will be as needed in the future, among other questions, Searle recommends.

“I always say, ‘I’m from Missouri—show me,’” he says, alluding to the state’s motto. “Let me see where you’re currently doing it. … Show me it running, so that I know this is not all smoke that you’re blowing. I’d like to talk to some of your customers to know what kind of reliability I can expect, and what kinds of runs times you are used to living up to. Is this a commonplace part that I can buy across the counter from one of my suppliers? And accuracy: I want to see some actual results, if you say you can hold these kinds of specifications, and you’ve done it already. A lot of that has to do with maintaining temperature.”

Snack and bakery companies need to focus on performance most of all, Johnson says. “How effectively does the machine season the product? What’s the accuracy and quality of coverage?”

Courtesy of Jenni Spinner

“Manufacturers are always looking at new products, formats, and SKUs, and inspection equipment needs to be flexible enough to support that.”

— Richard Reardon, general manager, Antares Vision Group