"The kneading process and the flours might be different for a bun vs. a bread vs. a cookie,” he says. “Depending on the level of complexity of the ingredients—do you put sugar in it, do you put salt it in, the amount of yeast—without some level of quality control, even if the baking process is the same, that might significantly affect the yield of the production. Otherwise, the customer might say, the recipe was the same today vs. tomorrow … but without knowing what’s changed on the material side, the product might turn out completely different.”

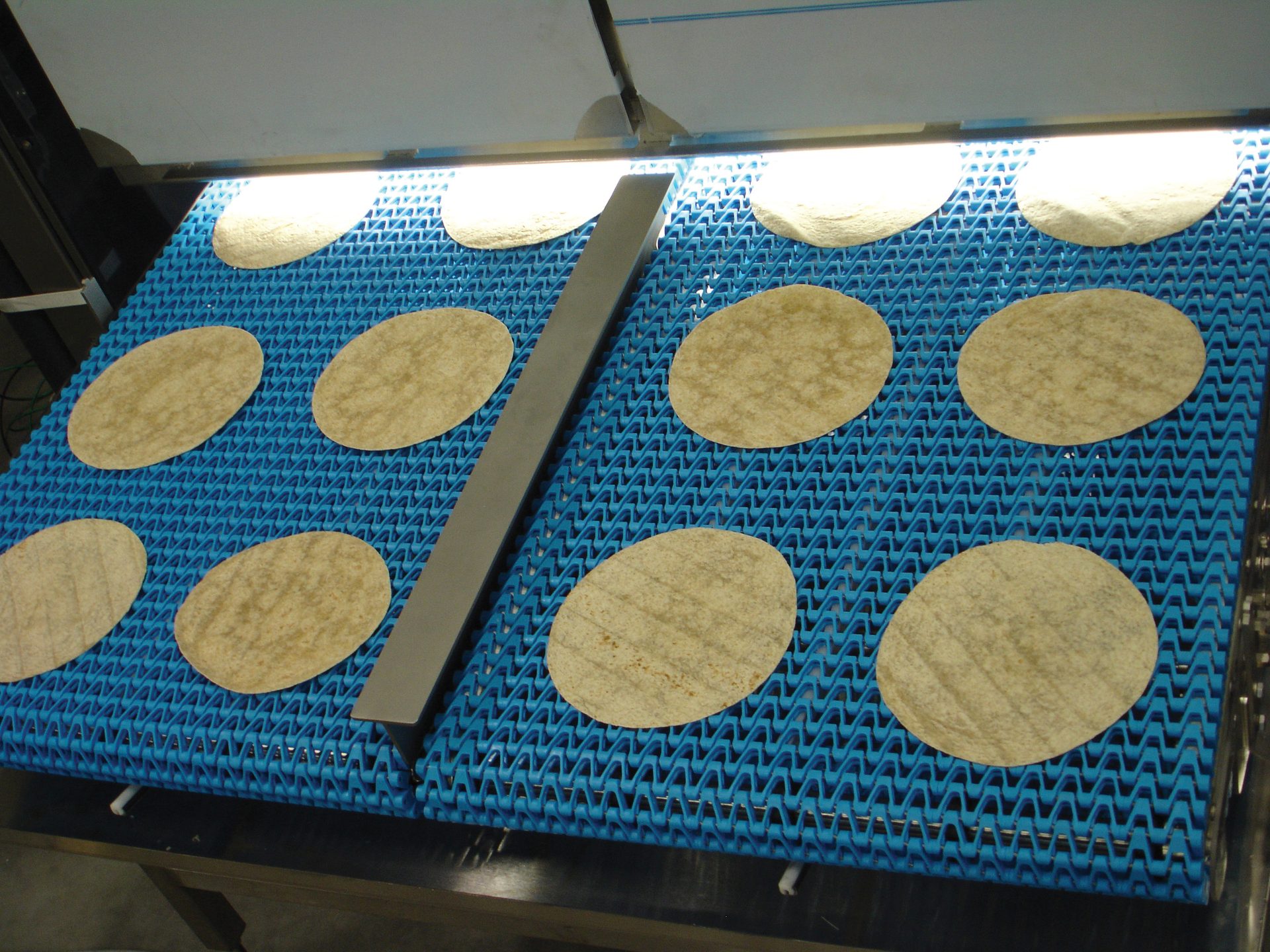

Zhao points to moisture as a particularly important process variable that changes rapidly throughout the process. “For example, a freshly baked cookie, right out of the oven, has a moisture level very different than it does 20 feet down the road before it goes into the freezer,” he comments. “If the process slows down for whatever reason—the packager breaks down, and the cookie must sit on the conveyor belt longer than it’s supposed to—understanding the moisture level throughout the process gives the manufacturer better control.”

Inspecting a product right out of the oven to look at colors, shapes, and volume can help the process engineer to understand whether the oven temperature might be too high, or the baking time too long, Zhao says. “People can feed that information back to the inputs to … have a self-control loop to improve the output of the process,” he advises.

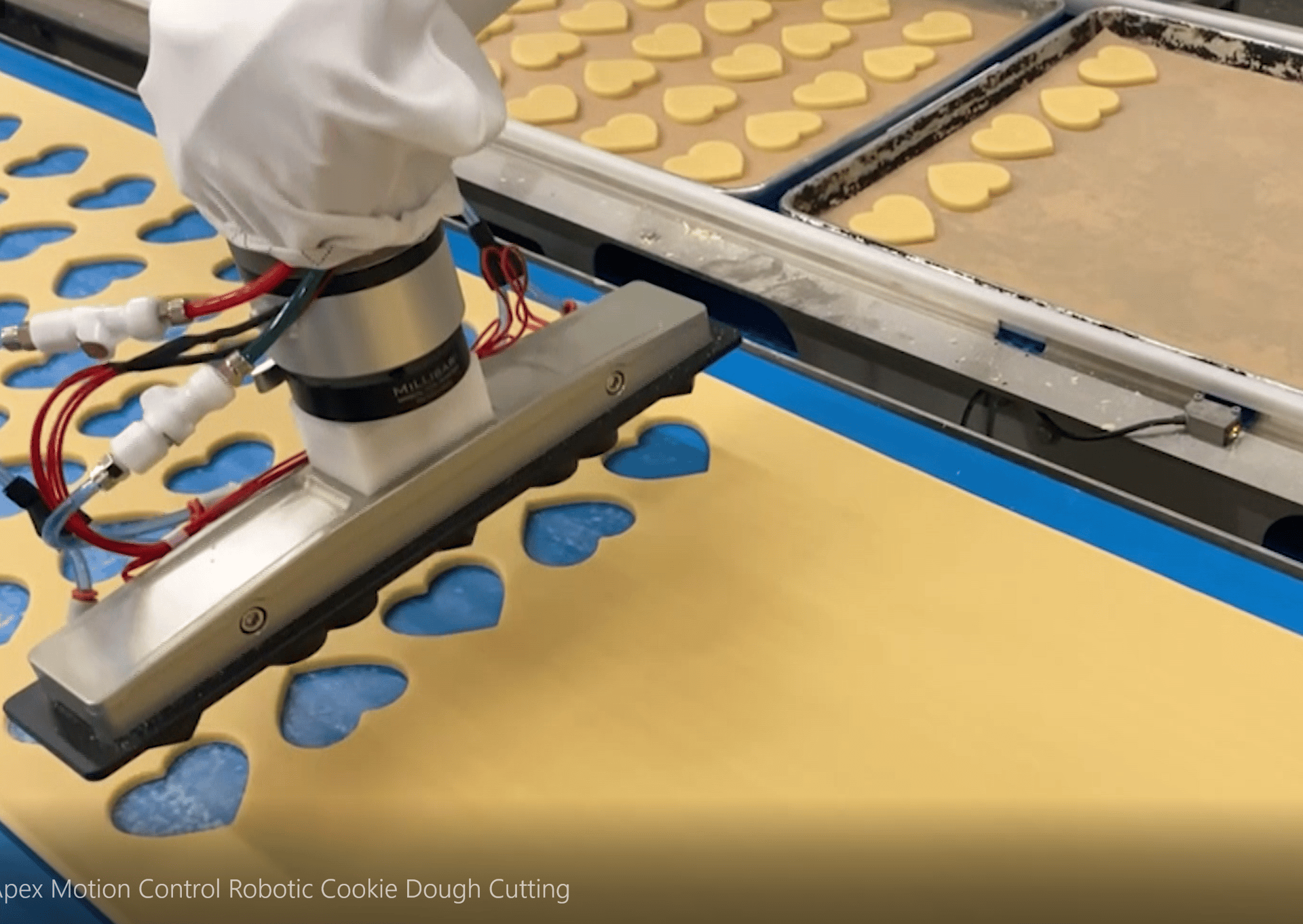

Customers often times experience yields between the mid-80s and low-90s before using automated production line to bring about a leaner process, Zhao says. “But with the automation and the vision and the feedback loop, they can get their yield to at least mid-90s,” he says. “That’s 5% to 10%, which easily translates to millions of dollars of savings every year.”

The Aspire Operational Excellence system at Aspire Bakeries, Northlake, IL, aims at sustainable continuous improvement by focusing on several elements, starting with the alignment of key process indicators (KPIs), which ensures that key indicators and goals align all the way from the bakery management team to the labor operators running the process, says Jody Holder, vice president of operational excellence, safety, and outsourced bakery solutions.

“Everyone should understand how their work contributes to achieving the bakery goals,” he says. “Another important element is monitoring our actual performance. We look to identify any gaps between our performance and the established targets. The more frequent monitoring, the better. At the baking processes, hour-by-hour results are logged and evaluated, with problem-solving efforts initiated, ongoing, if a gap is identified.” The cycle completes when the root cause of process disruptions is eliminated, leading to consistent improvement, she adds.

Overall equipment efficiency (OEE) is a top concern for bakery operations like Aspire, Holder says, noting that process equipment must be maintained effectively to prevent variations that could result in disruptions. “Poor equipment efficiency impacts overall performance in several ways,” he states. “For example, a piece of equipment running with uncontrolled variation could result in waste, reworks, and, ultimately, customer complaints. A significant downtime event could yield the same results, also affecting ability to meet customer demand.”