Industrial

packaging

The BOTTOM LINE

Sustainable ingredient packaging

Hygienic equipment is paramount

A look at equipment variations

Sanitary design, high levels of accuracy, easy maintenance and smart technology are features of new ingredient packaging machines, which process snack and bakery ingredients such as spices, flour, grains, and sugar. The equipment also is compatible with sustainable packaging solutions.

Spicing it up

Ingredient packaging machines feature the newest in sanitation, and provide easy maintenance.

Neal Lorenzi, Contributing Writer

Advanced options

Spee-Dee Packaging Machinery, Sturtevant, WI, designs and builds packaging machines that measure, dispense and weigh powders and dry granular products, primarily for the food industry.

The company’s net weight fillers are capable of filling pre-made bags, drums, and boxes with dry ingredients. The sanitary design of the equipment is suitable for these products, as well as for egg powders and dairy/whey-based products. “Our machines incorporate a servo-driven auger filler with a sealed hopper, which reduces airborne dust in the factory. Lately, we’ve seen an increase in demand for high protein nut-based products such as almond flour,” says Mark Navin, vice president of sales, Spee-Dee Packaging Machinery.

The company also offers the Spee-Dee Net Weight Bag Clamp auger filler, which has a small footprint and a hygienic design that makes it easy to clean. “The integration of a weigh cell with the filler means that the highest level of accuracy is achieved,” Navin adds.

Courtesy of Spee-Dee Packaging Machinery

Paxiom Group, Las Vegas, offers ingredient-packaging solutions that range from bulk powder/solids weighing, bagging, pouch filling, and container filling to end-of-line case packing and palletizing.

Paxiom Group engineered its V (vibratory) and T (tote filling) Model 25 automatic weigh filling machines for large-format filling applications. Built to handle 5 lbs. to 50 lbs., the PrimoLinear is suitable for wholesale, institutional, and foodservice requirements. Common packaging applications include weighing and filling of candy, frozen foods, fruits, baked goods, snack foods, and ingredients. Paxiom Group notes the equipment’s PC controls allow for unlimited recipe storage.

Courtesy of Paxiom Group

The PrimoLinear C and IW Series weigh filling machines are designed to weigh/fill sticky, damp, wet, and difficult-to-move products, as well as those that require gentle handling. The series uses conveyor belts as opposed to traditional vibratory feed pans to carry product to the weighing station. “Manufactured in stainless steel, our conveyorized weigh filling machines are available in single- and twin-lane configurations, depending on speeds. Standard features include stainless steel frame, easily removable conveyor belts, and large color touchscreen,” says Val Miller, digital marketing specialist and project manager, Paxiom Group.

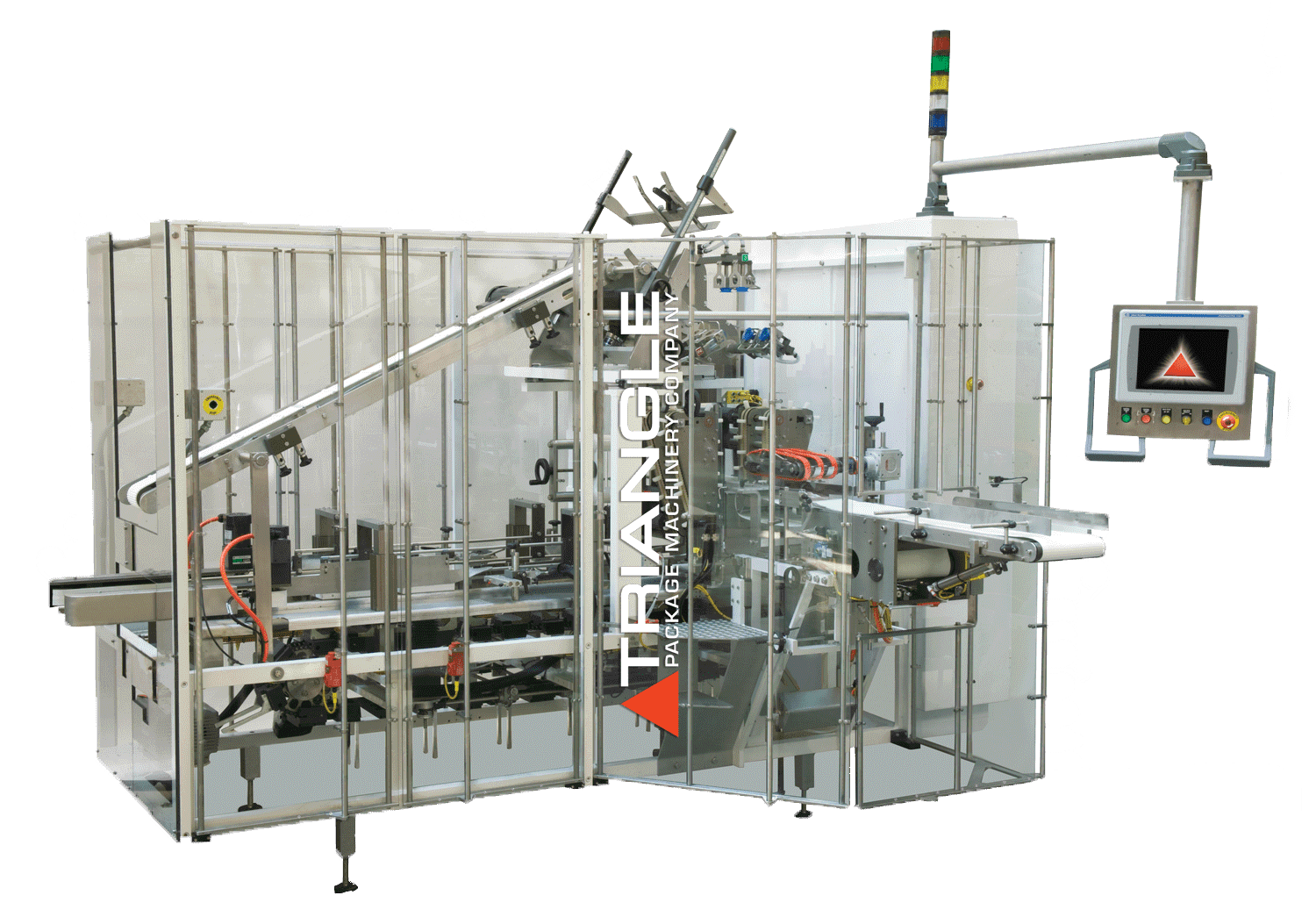

The new Delta bagger is designed for ease of operation, with quick and easy changeover. The Delta also features a solid sanitary design and can make bags up to 15 inches wide and up to 20 inches long in a single pull. “We’ve also added smart technology features, such as IO Link enabled sensors,” says Kim Magon-Haller, marketing manager, Triangle Package Machinery Co.

Courtesy of Triangle Package Machinery Co.

“We’ve also added smart technology features, such as IO Link enabled sensors.”

— Kim Magon-Haller, marketing manager, Triangle Package Machinery Co.

Model CSB (Compact Sanitary Bagger) from Triangle features a compact footprint of 36 inches, and it can run bags up to 13 inches wide. To maximize production, it can be paired in a dual configuration with a split scale, so users can improve product throughput without utilizing a lot of floor space. This option also lets users run each bagger individually, so they can perform routine maintenance without shutting down an entire line.

For bakery and snack producers who run pre-made bags, the Triangle/JDD Rotary Pouch Machine can fill and seal Doy bags, 3-sided seal, flat, and stand-up pouches, as well as zippered bags, at speeds of up to 50 pouches per minute. With the ability to store up to 48 recipes, it allows users to change package styles with the push of a button. “It is ideal for a variety of ingredients, including sugar and powders, as well as baking mixes, granola, and snacks,” says Magon-Haller.

Another machine that offers quick changeover is Triangle’s Flex 1 Cartoner, which is designed for bag-in-box applications that involve baking mixes, sugar, cereal, granola, crackers, and snacks. Servo drives offer intermittent motion control, so no bagger sync is required. “Unlike traditional cartoners, the Flex 1 allows users to run multiple carton sizes and achieve changeover to full production in less than 15 minutes,” Magon-Haller adds.