Efficiency is the name of the game across all aspects of the food industry. For snack and bakery companies managing varying degrees of their product distribution, including direct-store delivery (DSD) routes, streamlining operations can come in many forms, including new technologies.

“In an industry where time and temperature controls are paramount, technology that goes beyond visibility is vital,” says Kendra Phillips, chief technology officer and vice president of new products, Ryder System, Inc., Miami.

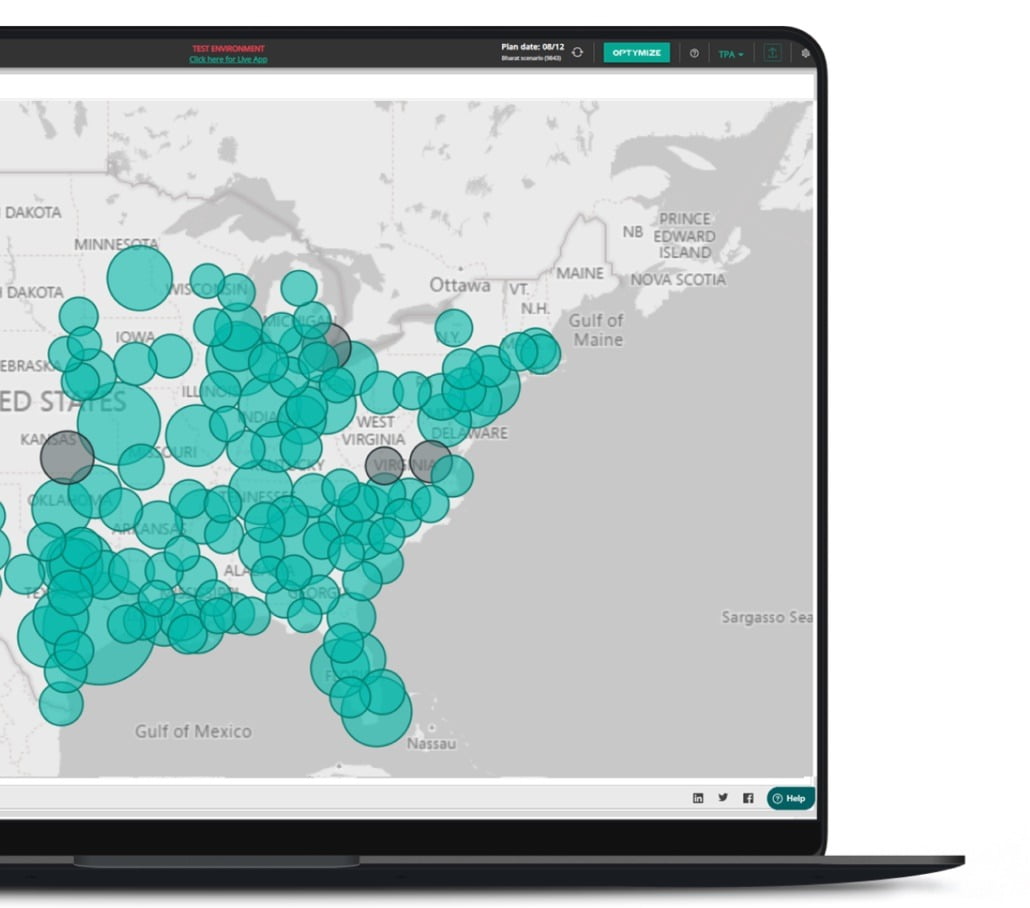

Ryder Systen developed its new RyderShare collaborative logistics platform to bring a straightforward level of visibility to supply-chain operations. Phillips notes the platform lets everyone involved in moving goods through the supply chain, including shippers, receivers, carriers, and service providers, to not only see across their supply chains in real time, but to collaborate and take proactive action to course-correct and avoid costly delays.

“The need for this kind of groundbreaking technology has never been more apparent,” says Phillips. “When the pandemic upended supply chains providing food and other essential goods to homes and businesses worldwide, early adopters of RyderShare proved much more resilient to the disruption. We had one customer, in particular, that experienced a nearly 50 percent increase in sales almost overnight. Before RyderShare, they would have had to rely on phone calls and emails to communicate changes in truckload deliveries to thousands of stores—an impossible task. With RyderShare, the technology automatically calculated the new routes and ETAs and then sent real-time tracking information to the stores, so they could plan accordingly.”